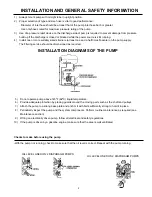

INSTALLATION AND GENERAL SAFETY INFORMATION

1) Always mount pump with oil sight tube in upright position.

2) Proper selection of type and size hose is vital to good performance:

- Diameter of inlet hose should be at least that of the pump inlet hose barb or greater.

- Use only hoses rated for maximum pressure rating of the pump.

3) Use of a pressure relief device on the discharge side of pump is required to prevent damage from pressure

build up if the discharge is closed or blocked while the power source is still running.

4) Install one or more suitably sized strainers (at least one and a half times flowrate) on the pump supply.

The filtering service should be dimensioned as required.

5) Do not operate pump above 145ºF (62ºC) liquid temperature.

6) Provide adequate protection by placing guards around the moving parts such as the shaft and pulleys.

7) Attach the pump to a strong base plate and anchor it with bolts sufficiently strong to hold it in place.

8) Periodically inspect the pump and the system components. Perform routine maintenance as required (see

Maintenance section).

9) Wiring an electrically driven pump, follow all electrical and safety regulations.

10) If the pump is driven by a gasoline engine, make sure that the area is well ventilated.

Checks to make before using the pump

-With the pump not running, check to make sure that the oil level is correct. Repeat with the pump running.

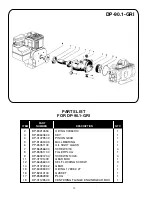

INSTALLATION DIAGRAMS OF THE PUMP

2

OIL LEVEL USED ON 2 DIAPHRAGM PUMPS

OIL LEVEL USED ON 2 DIAPHRAGM PUMPS