15

CDL Maple Sugaring Equipment Inc.

BOILING

1.

Defoamers are needed to keep the evaporator running smoothly. If the syrup

generates too much foam, the float boxes will be unable to operate properly. This may

lead to unstable water levels and a possible water shortage. The defoamer also

prevents syrup from overflowing.

2.

Pay special attention to the front and rear water levels; adjust as needed using the

crank on each float.

3.

The maple syrup is ready when it reaches 7 degrees above the boiling point of water.

Open the valve when the syrup temperature reaches this level and close the valve once

the temperature drops below 7 again. Do not heat the furnace if the syrup is almost

ready. The temperature beneath the syrup pans will be too high and the syrup may

burn. Heat after you have drawn off the syrup.

4.

Repeat the previous step every time the temperature reaches 7 degrees above boiling.

Your draw may vary over a single day of boiling. This is caused by a change in

atmospheric pressure. Be careful and calibrate your syrup regularly using a

hydrometer, densitometer or refractometer, all available at your local CDL store.

5.

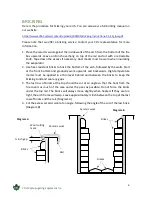

Once you have more experience, you can decrease the sap level in your pans. The ideal

level is 1 inch above the flues in the flue pan and 1½

–

2 inches in the syrup pans. The

lower the level, the faster the boil. However, lower levels also increase the risk of

burning the pans.

IMPORTANT:

Check the door temperature by placing your hand on the door. The door

may be hot to the touch, but

NEVER

burning hot. If it gets too hot, you will need to add

some air. The goal is to keep the door hot, but not burning.

IMPORTANT SAFETY NOTE

IF A POWER FAILURE OCCURS, TURN THE BLOWER OFF AND LEAVE THE EVAPORATOR

DOOR AJAR BY ½ INCH. THIS WILL SUPPLY ENOUGH AIR TO SAFELY FINISH BURNING THE

REMAINING WOOD IN THE EVAPORATOR.

If you have any problems, you can reach one of our technicians by calling 800-883-5158

or your CDL representative.