Page

18

of

22

3.5

Air cooling

3.5.1 Pressurized air

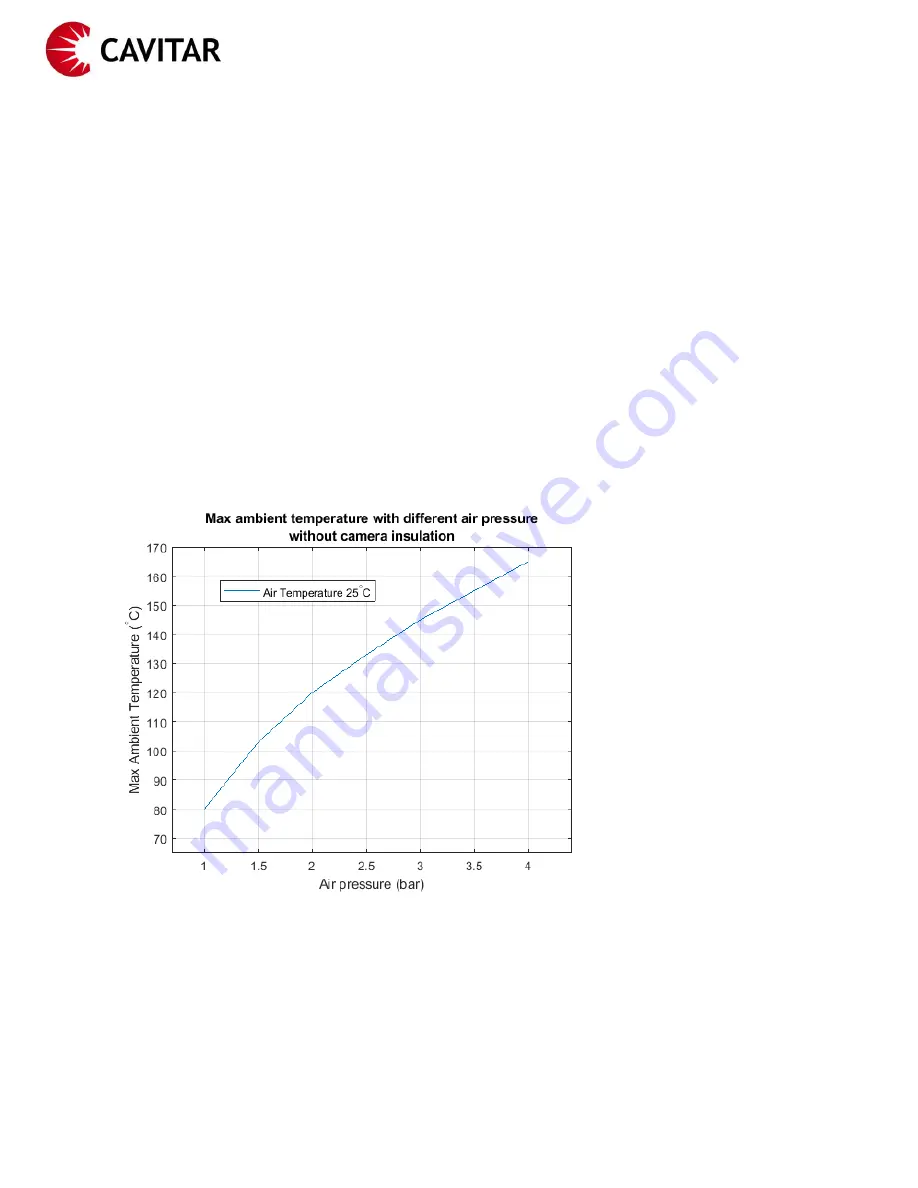

Pressurized air can be applied simply by connecting the incoming air hose to either cooling connector of

the welding camera. The air will come out from the second cooling connector of the camera. This air can

be guided to desired location with a second hose (can also be utilized in air knife). If the camera and cables

are insulated (e.g. inside an air-tight thermally insulating protective sleeve such as pyrojacket), the

exhaust air can also be used for keeping the air inside the protective sleeve cooler. This is very useful in

keeping the cables sufficiently cool. In this case there is no need to connect anything to the second cooling

connector of the camera (the alumini

um foil around the cables shouldn’t be applied in order not to

obstruct the exhaust air flow). The exhaust air can be forced to travel back inside the protective sleeve by

sealing the camera end of the insulation (see Figs. 3.5 or 3.8). Pressurized air should be sufficiently pure

(no water or oil) and the pressure shouldn’t

be excessive. Ideal temperature for the pressurized air is

~25

…30

°C (to avoid condensation and enable efficient cooling). Fig. 3.13 shows the maximum ambient

temperature (camera temperature reaching 55 °C) with different air pressures (cables insulated, camera

not insulated, see Figs 3.2, 3.3 and 3.6-3.8; return air not cooling the air inside the protective sleeve).

Fig 3.13. Maximum ambient temperature with different air pressures.

3.5.2 Vortex pipe

Vortex pipes can improve the efficiency of air cooling substantially. However, special attention must be

paid to avoid condensation and for this reason vortex pipes can only be considered if the user is

experienced with vortex pipes and can be certain that there is no risk of condensation. Otherwise same

principles as with conventional pressurized air apply.