MODELS 8310HP DIFFERENTIAL

(1+6 and 1+8 ) PRESSURE REDUCING REG U LA TORS

SECTION l

l. DESCRIPTION AND SCOPE

The Models 8310HP-1+6 and 8310HP-1+8 are differential reducing regulators used to control dif fer en tial pressure between

downstream (outlet or P

2

) pressure and a loading (P

Load

) pressure to the spring chamber. Available in sizes 1-1/2" (DN40), 2"

(DN50), 2-1/2" (DN65), 3" (DN80) and 4" (DN100). Widely applied in steam atomization systems using heavy oil (Nos. 3-6,

Bunker C) to fuel burners. Refer to Tech ni cal Bulletin 8310HP-DIFF-TB for design conditions and selection recommendations.

SECTION II

II. INSTALLATION

IOM-8310HP-DIFF

06/16

7. Clean the piping of all foreign material including chips,

welding scale, oil, grease and dirt before in stall ing the

regulator. Strainers are rec om mend ed.

8. In placing thread sealant on pipe ends prior to

en gage ment, ensure that excess material is re moved

and not allowed to enter the regulator upon start-up.

9. Flow Direction: Install so the flow direction match es

the arrow cast on the body. Install an external sensing

line (1/2" O.D. (DN15) tubing minimum) from the 3/8"

(DN10) NPT con nec tion in needle valve (39) to a point

down stream, pref er a bly at gauge location.

10. Install oil loading pressure sensing line to spring chamber

(13) connection.

11. For long operational life with minimum maintenance,

install a strainer in the upstream line. If regulator pipe

line is ex pand ing to a larger pipe line, always connect

sensing line to the larger pipe line.

12. For best performance, install in well drained hor i zon tal

pipe, properly trapped, if a steam service ap pli ca tion.

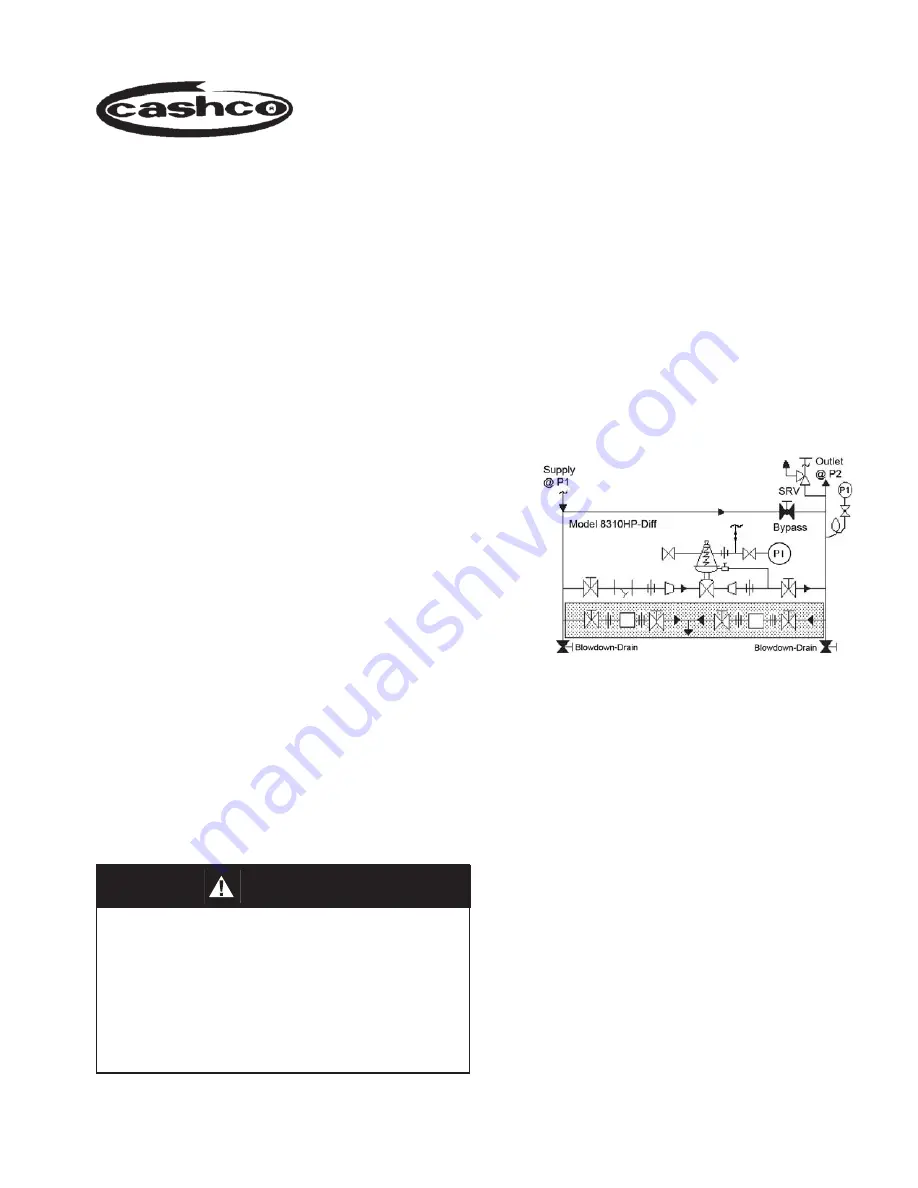

Recommended Piping Schematic For

Pressure Reducing Station

1. An inlet block valve should always be installed. An outlet

block valve is desirable.

2. A manual bypass valve is recommended for “hot piping”

systems to assist in piping warm-up at startup.

3. An isolation valve on the loading line is not recommended.

The threaded port in the diaphragm ring (25) for the

Model 8310HP 1+8 may be piped to a safe drainage

point, but no valve should be installed in the drain line.

4. Pipe unions are recommended for NPT screwed

in stal la tions to allow removal from piping.

5. An outlet pressure gauge should be located

ap prox i mate ly ten pipe diameters downstream, and

within sight. A loading pressure (or differential pressure)

gauge is rec om mend ed.

6. All installations should include a downstream re lief

device if the inlet pressure could exceed the pres sure

rating of any downstream equipment or the max i mum

outlet pressure rating of the unit.

INSTALLATION, OPERATION & MAINTENANCE MANUAL

(Shaded portion for steam/condensate systems)

CAUTION

DO NOT HYDROSTATIC TEST THRU AN IN STALLED

UNIT; ISOLATE REGULATOR FROM TEST. DO NOT

HY DRO STAT IC TEST THE LOADING PRESSURE

WITH OUT PRESSURE IN THE MAIN REGULATOR.

The upper range spring pressure level listed on the name plate

is the rec om mend ed “up per operative limit” for the sens ing

di a phragm (see Section IV. Start-up, Number 7.) High er pres-

sures could cause internal damage. In ad di tion, note on the

name plate that the Inlet and Outlet pres sure and tem per a ture

ratings are at dif fer ent levels.

TR

TR

ISO Registered Company