On machines with independently operated wheel brakes, lock the brake pedals together when roading to provide

equalized brake applications.

Dual brake pedals (if equipped) should be locked together for road travel.

Use the safety chains for trailed equipment.

Lift implements and attachments high enough above the ground to prevent accidental contact with road.

When transporting equipment or machine on a transport trailer, ensure the machine is properly secured. Ensure the

Slow Moving Vehicle sign (SMV) on the equipment or machine is covered while being transported on a trailer.

Be aware of overhead structures or power lines. Ensure the machine and/or attachments can pass safely under.

Travel speed should be such that complete control and machine stability is maintained at all times.

Slow down and signal before turning.

Pull over to allow faster traffic to pass.

Follow the correct towing procedure for equipment with or without brakes.

Fire and Explosion Prevention

Fuel or oil on hot surfaces or electrical components can cause a fire.

Trash, debris, or flammable material can ignite on hot surfaces.

Always have a fire extinguisher on or near the machine.

Ensure the fire extinguisher(s) is maintained and serviced according to the manufacturer’s instructions.

At least once each day and at the end of the day remove all trash and debris from the machine. Ensure no debris is

near hot components such as engine, transmission, exhaust, battery, etc. More frequent cleaning of your machine

may be necessary depending on the operating environment and conditions.

At least once each day, remove debris accumulation around moving components such as bearings, pulleys, belts,

gears, cleaning fan, etc. More frequent cleaning of your machine may be necessary depending on the operating

environment and conditions.

Inspect the electrical system for loose connections or frayed insulation. Repair or replace loose or damaged parts.

Do not store oily rags or other flammable material on the machine.

Do not weld or flame cut any items that contain flammable material. Clean items thoroughly with non-flammable

solvents before welding or flame-cutting.

Do not expose the machine to flames, burning brush, or explosives.

Promptly investigate any unusual smells or odors that may occur during operation of the machine.

General Battery Safety

Always wear eye protection when working with batteries.

Do not create sparks or have open flame near battery.

Ventilate when charging or using in an enclosed area.

Disconnect negative (-) first and reconnect negative (-) last.

When welding on the machine, disconnect both terminals of the battery.

Do not weld, grind, or smoke near a battery.

1-7

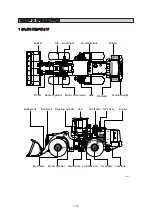

Содержание 1221F

Страница 13: ......

Страница 41: ...This as a preview PDF file from best manuals com Download full PDF manual at best manuals com ...