6028021 Rev. 1

11

ERIODIC MAINTENANCE

P

100-Hour

Maintenance

Every time the lift truck is serviced or every 100 hours of

truck operation, whichever comes first, complete the

following maintenance procedures:

• Check for loose or missing bolts, worn or damaged

hoses and hydraulic leaks.

• Check edges of contact pads for wear or sharp nicks

that could damage or tear paper rolls. Grind edges

smooth.

• Check contact pad pivot joints for wear and replace

or repair if necessary (see Service Manual).

• Check that load holding hydraulic system is function-

ing properly. Clamp Force Indicators 831887, 830141

and 832442 are available for this test.

• Check decals and nameplate for legibility.

500-Hour

Maintenance

After each 500 hours of truck operation, in addition to the

100-hour maintenance, perform the following proce-

dures:

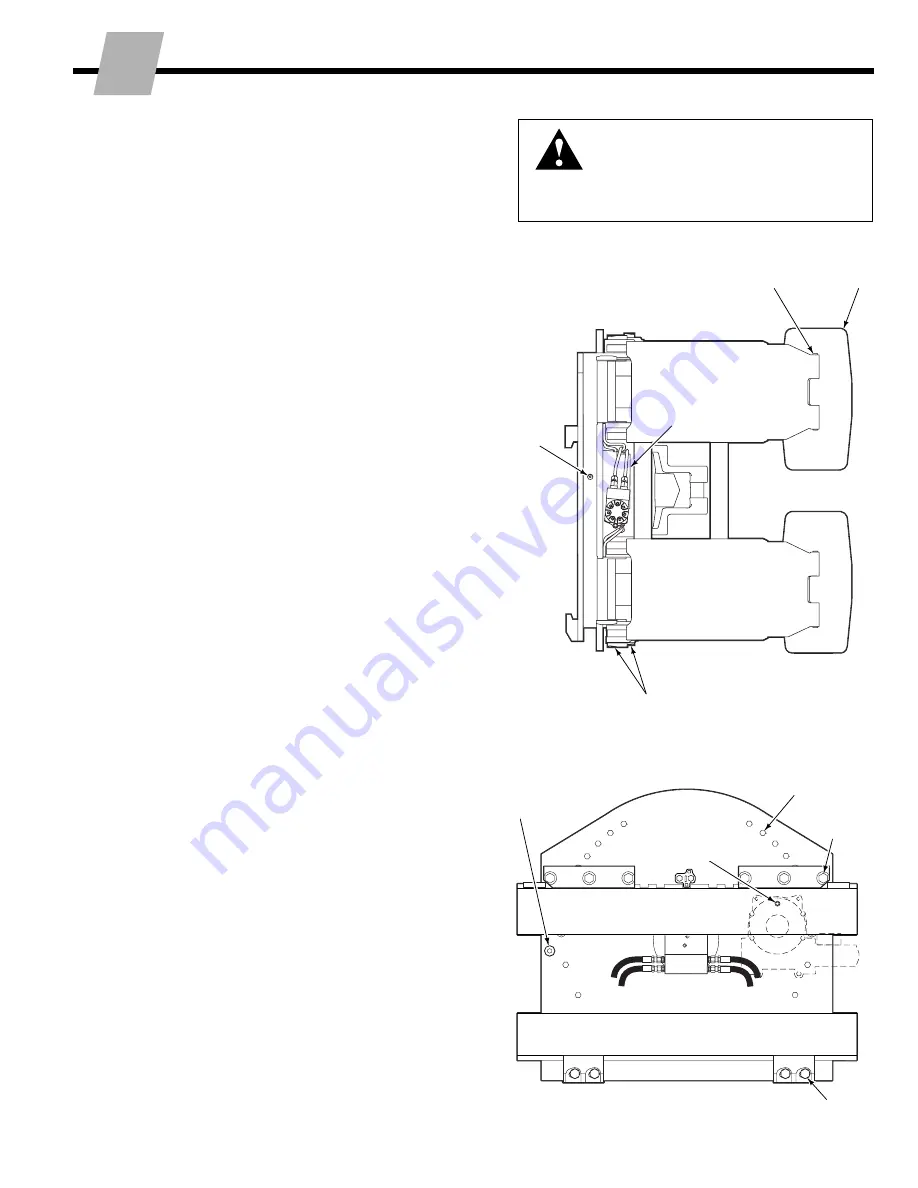

• Tighten baseplate-to-bearing assembly capscrews to

75 ft.-lbs. (95 Nm).

• Tighten faceplate-to-bearing assembly capscrews to

75 ft.-lbs. (95 Nm).

NOTE:

Access capscrews

through plug in baseplate (see illustration).

• Lubricate rotator bearing assembly with wheel bearing

grease. Rotate clamp in 90-degree increments and

grease in each position.

• Tighten all mounting hook capscrews to 260 ft.-lbs.

(350 Nm).

• Check rotator drive gearcase lubricant level. Rotate

clamp so rotator drive is upright and remove small hex

socket plug from top of front cover. Lubricant should

run out of hole. If necessary, rotate Clamp 90

degrees and fill with Cascade Rotator Drive Lubricant,

Part No. 656300, or SAE 90 wt. gear lube (AGMA

'mild' 6 EP Gear Oil).

CAUTION:

Replace check plug using Loctite 271.

• Inspect all arm and cylinder pivot bushings for wear

and replace if necessary (see Service Manual

674512).

• Inspect all load-bearing structural welds on arms,

swing frame pivots, arm pivots and cylinder pivot

areas for visual cracks. Replace components as

required.

2000-Hour

Maintenance

After each 2000 hours of truck operation, in addition to

the 100 and 500-hour maintenance, perform the following

procedures:

• Inspect all arm and cylinder pivot pins for wear and

replace if necessary (see Service Manual 6028021).

WARNING:

After completing any service

procedure, always test the Clamp

through five complete cycles. First test

empty, then test with a load to make sure

the Clamp operates correctly before

returning it to the job.

Arm, Cylinder Pivot Pins, Bushings

RC0957.ill

Rotator

Bearing

Assembly

Grease

Fitting

RC0929.ill

Contact

Pad Edges

Rotator Drive

Contact Pad

Pivot Joints

Long Arm Side

Lower Hook

Capscrews

Baseplate-to-Bearing

Assembly Capscrews

Upper Hook

Capscrews

FX-Series Back (Driver's) View

Rotator Drive

Lubricant Level

Check Plug

(front side)

Access Plug for

Faceplate-to-Bearing

Assembly Capscrews