INSTALLATION

6

6914838 EN

IN0019.eps

IN0018.eps

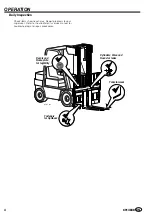

Truck Requirements

GA0082.eps

Auxiliary Valve Functions

Check for compliance with ANSI (ISO) standards:

Sideshift

Left

Hoist Up

Tilt Back

Tilt Forward

Sideshift

Right

Hoist Down

Open Forks (if equipped)

Close Forks (if equipped)

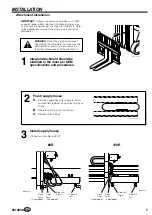

Hydraulic Supply

Fork Positioning and Sideshift function:

No. 8 hose/

No. 8 fittings with 10 mm minimum ID.

Refer to Cascade

Hose & Cable Reel Selection Guide

,

Part No. 212199 to select the correct hose reel for the

mast and truck.

A

Fork Positioning & Sideshifting

A

Mast Double Internal Reeving

OR

C

Mast Single Internal Reeving and Hose Reel

B

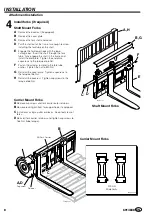

Truck Relief Setting

152 bar Recommended

241 bar Maximum

Truck Flow Volume

➀

Min.

➁

Recommended Max.

➂

80R/100R-IFS

80R/100R-ISS

4 L/min.

7.5 L/min.

12 L/min.

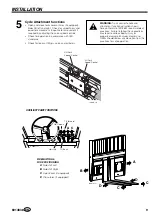

➀

Cascade R-Series Integral Attachments are compatible with

SAE 10W petroleum base hydraulic fluid meeting Mil. Spec.

MIL-0-5606 or MIL-0-2104B. Use of synthetic or aqueous base

hydraulic fluid is not recommended. If fire resistant hydraulic

fluid is required, special seals must be used. Contact Cascade.

➁

Flow less than recommended will result in slow fork positioning

and sideshift speed.

➂

Flow greater than maximum can result in excessive heating,

reduced system performance and short hydraulic system life.

Sideshifting

A

Mast Single Internal Reeving

OR

B

Hose Reel

C

Содержание 100R

Страница 17: ...Blank...