7

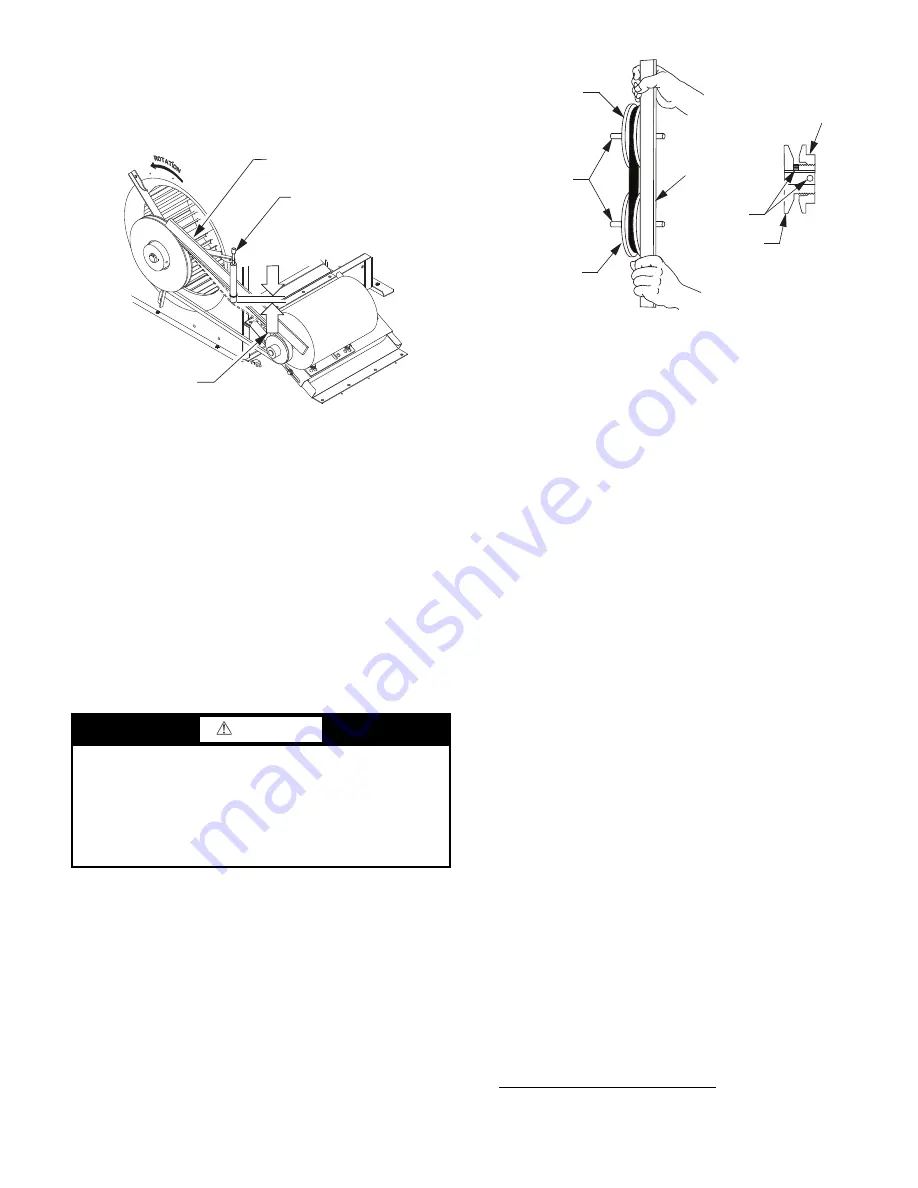

Adjust belt tension by loosening the motor mounting plate

front and rear bolts and sliding the plate toward the fan (to re-

duce tension) or away from fan (to increase tension). Ensure

the blower shaft and the motor shaft are parallel to each other

(pulleys aligned). When finished, tighten all bolts and torque to

65 to 70 in.-lb (7.4 to 7.9 Nm).

Fig. 12 — Checking Blower Motor Belt Tension

Replacing the Belt

NOTE: Use a belt with same section type or similar size. Do not

substitute a FHP-type belt. When installing the new belt, do not

use a tool (screwdriver or pry-bar) to force the belt over the pulley

flanges; this will stress the belt and cause a reduction in belt life.

Damage to the pulley can also occur.

Use the following steps to replace the V-belt. See Fig. 11.

1. Loosen the front and rear motor mounting plate bolts.

2. Push the motor and its mounting plate towards the blower

housing as close as possible to reduce the center distance

between fan shaft and motor shaft.

3. Remove the belt by gently lifting the old belt over one of

the pulleys.

4. Install the new belt by gently sliding the belt over both

pulleys and then sliding the motor and plate away from the

fan housing until proper tension is achieved.

5. Check the alignment of the pulleys and adjust if necessary.

6. Tighten all bolts and torque to 65 to 70 in.-lb (7.4 to

7.9 Nm).

7. Check the tension after a few hours of runtime and re-

adjust as required.

ADJUSTABLE-PITCH PULLEY ON MOTOR

The motor pulley is an adjustable-pitch type that allows a ser-

vicer to implement changes in the fan wheel speed to match as-

installed ductwork systems. The pulley consists of a fixed

flange side that faces the motor (secured to the motor shaft)

and a movable flange side that can be rotated around the fixed

flange side that increases or reduces the pitch diameter of this

driver pulley. (See Fig. 13.)

Fig. 13 — Supply-Fan Pulley Adjustment

As the pitch diameter is changed by adjusting the position of

the movable flange, the centerline on this pulley shifts laterally

(along the motor shaft). This creates a requirement for a re-

alignment of the pulleys after any adjustment of the movable

flange. Reset the belt tension after each realignment.

Inspect the condition of the motor pulley for signs of wear.

Glazing of the belt contact surfaces and erosion on these sur-

faces are signs of improper belt tension and/or belt slippage.

Replace pulley if wear is excessive.

Changing the fan speed:

1. Shut off unit power supply. Use proper lockout/tag-out

procedures.

2. Loosen belt by loosening fan motor mounting nuts. (See

Fig. 11.)

3. Loosen movable pulley flange setscrew. (See Fig. 13.)

4. Screw movable flange toward fixed flange to increase

speed and away from fixed flange to decrease speed.

Increasing fan speed increases load on motor. Do not

exceed the maximum specified speed.

5. Set movable flange at nearest keyway of pulley hub.

Tighten setscrew and torque to 65 to 70 in.-lb (7.4 to

7.9 Nm).

ALIGNING BLOWER AND MOTOR PULLEYS:

1. Loosen blower pulley setscrews.

2. Slide blower pulley along blower shaft. Make angular

alignment by loosening motor mounting plate front and

rear bolts.

3. Tighten blower pulley setscrews and motor mounting

bolts. Torque bolts to 65 to 70 in.-lb (7.4 to 7.9 Nm).

4. Recheck belt tension.

Bearings

The fan system uses bearings featuring concentric split locking

collars. A Torx

1

T-25 socket head cap screw is used to tighten

the locking collars. Tighten the locking collar by holding it

tightly against the inner race of the bearing. Tighten the socket

head cap screw. Torque cap screw to 65 to 70 in.-lb (7.4 to

7.9 Nm). See Fig. 14. Check the condition of the motor pulley

for signs of wear. Glazing of the belt contact surfaces and ero-

sion on these surfaces are signs of improper belt tension and/or

belt slippage. Pulley replacement can be necessary.

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this CAUTION can result in premature

wear and damage to equipment.

Do not use a screwdriver or a pry bar to place the new V-

belt in the pulley groove. This can cause stress on the V-belt

and the pulley resulting in premature wear on the V-belt

and damage to the pulley.

BROWNING BELT

TENSION CHECKER

STRAIGHTEDGE

1/2”

(1.3 cm)

BELT

DEFLECTION

1. Torx is a registered trademark of Acument Intellectual Properties,

LLC.

STRAIGHT EDGE

MUST BE PARALLEL

WITH BELT

SETSCREWS

MOTOR AND

FANSHAFTS

MUST BE

PARALLEL

FIXED FLANGE

MOVABLE

FLANGE

SINGLE - GROOVE

FAN PULLEY

MOTOR PULLEY

Содержание WeatherMaster 50HC04

Страница 32: ...32 Fig 63 RTU Open Overlay for Economizer Wiring ...

Страница 33: ...33 Fig 64 VFD Overlay for W2770 Controller Wiring ...

Страница 85: ...85 Fig B 50HC A04 A06 PAC Control Diagram 208 1 60 208 230 3 60 460 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 86: ...86 Fig C 50HC A07 PAC Control Diagram 208 230 3 60 460 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 89: ...89 Fig F 50HC D08 D09 PAC Control Diagram 208 230 3 60 460 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 90: ...90 Fig G 50HC D11 PAC Control Diagram 208 230 3 60 460 3 60 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 91: ...91 Fig H 50HC D12 PAC Control Diagram 208 230 3 60 460 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 92: ...92 Fig I 50HC D14 PAC Control Diagram 208 230 3 60 460 3 60 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 93: ...93 Fig J 50HC A04 A06 PAC Power Diagram 208 230 1 60 APPENDIX D WIRING DIAGRAMS ...

Страница 94: ...94 Fig K 50HC A04 A06 PAC Power Diagram 208 230 3 60 460 3 60 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 95: ...95 Fig L 50HC A07 PAC Power Diagram 208 230 3 60 460 3 60 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 98: ...98 Fig O 50HC D07 PAC Power Diagram 575 3 60 6 Ton 2 Stage with Dehumidification APPENDIX D WIRING DIAGRAMS ...

Страница 99: ...99 Fig P 50HC D08 D09 PAC Power Diagram 208 230 3 60 460 3 60 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 100: ...100 Fig Q 50HC D11 PAC Power Diagram 208 230 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 101: ...101 Fig R 50HC D11 PAC Power Diagram 460 3 60 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 102: ...102 Fig S 50HC D12 PAC Power Diagram 208 230 3 60 460 3 60 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 103: ...103 Fig T 50HC D14 PAC Power Diagram 208 230 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 104: ...104 Fig U 50HC D14 PAC Power Diagram 460 3 60 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 109: ...109 Fig Z 50HC D12 PAC Control Diagram 230 460 575 3 60 with Humidi MiZer System APPENDIX D WIRING DIAGRAMS ...

Страница 110: ...110 Fig AA 50HC D14 PAC Control Diagram 230 460 575 3 60 with Humidi MiZer System APPENDIX D WIRING DIAGRAMS ...

Страница 111: ...111 Fig AB 50HC A04 A06 PAC Power Diagram 208 230 1 60 with Humidi MiZer System APPENDIX D WIRING DIAGRAMS ...

Страница 112: ...112 Fig AC 50HC A04 A06 PAC Power Diagram 208 230 460 3 60 with Humidi MiZer System APPENDIX D WIRING DIAGRAMS ...

Страница 113: ...113 Fig AD 50HC A04 A06 PAC Power Diagram 575 3 60 with Humidi MiZer System APPENDIX D WIRING DIAGRAMS ...

Страница 114: ...114 Fig AE 50HC A07 PAC Power Diagram 208 230 460 3 60 with Humidi MiZer System APPENDIX D WIRING DIAGRAMS ...

Страница 115: ...115 Fig AF 50HC A07 PAC Power Diagram 575 3 60 with Humidi MiZer System APPENDIX D WIRING DIAGRAMS ...

Страница 116: ...116 Fig AG 50HC D08 D09 PAC Power Diagram 208 230 460 3 60 with Humidi MiZer System APPENDIX D WIRING DIAGRAMS ...

Страница 117: ...117 Fig AH 50HC D08 D09 PAC Power Diagram 575 3 60 with Humidi MiZer System APPENDIX D WIRING DIAGRAMS ...

Страница 118: ...118 Fig AI 50HC D11 PAC Power Diagram 208 230 3 60 with Humidi MiZer System APPENDIX D WIRING DIAGRAMS ...

Страница 119: ...119 Fig AJ 50HC D11 PAC Power Diagram 460 3 60 575 3 60 with Humidi MiZer System APPENDIX D WIRING DIAGRAMS ...

Страница 121: ...121 Fig AL 50HC D14 PAC Power Diagram 208 230 3 60 with Humidi MiZer System APPENDIX D WIRING DIAGRAMS ...

Страница 122: ...122 Fig AM 50HC D14 PAC Power Diagram 460 3 60 with Humidi MiZer System APPENDIX D WIRING DIAGRAMS ...

Страница 123: ...123 Fig AN 50HC D14 PAC Power Diagram 575 3 60 with Humidi MiZer System APPENDIX D WIRING DIAGRAMS ...

Страница 124: ...124 Fig AO PremierLink System A04 A06 Wiring Diagram APPENDIX D WIRING DIAGRAMS ...

Страница 125: ...125 Fig AP RTU Open System Control A04 A06 Wiring Diagram APPENDIX D WIRING DIAGRAMS ...

Страница 126: ...126 Fig AQ PremierLink System A07 D14 Wiring Diagram APPENDIX D WIRING DIAGRAMS ...

Страница 127: ...127 Fig AR RTU Open A07 D14 Wiring Diagram APPENDIX D WIRING DIAGRAMS ...