36

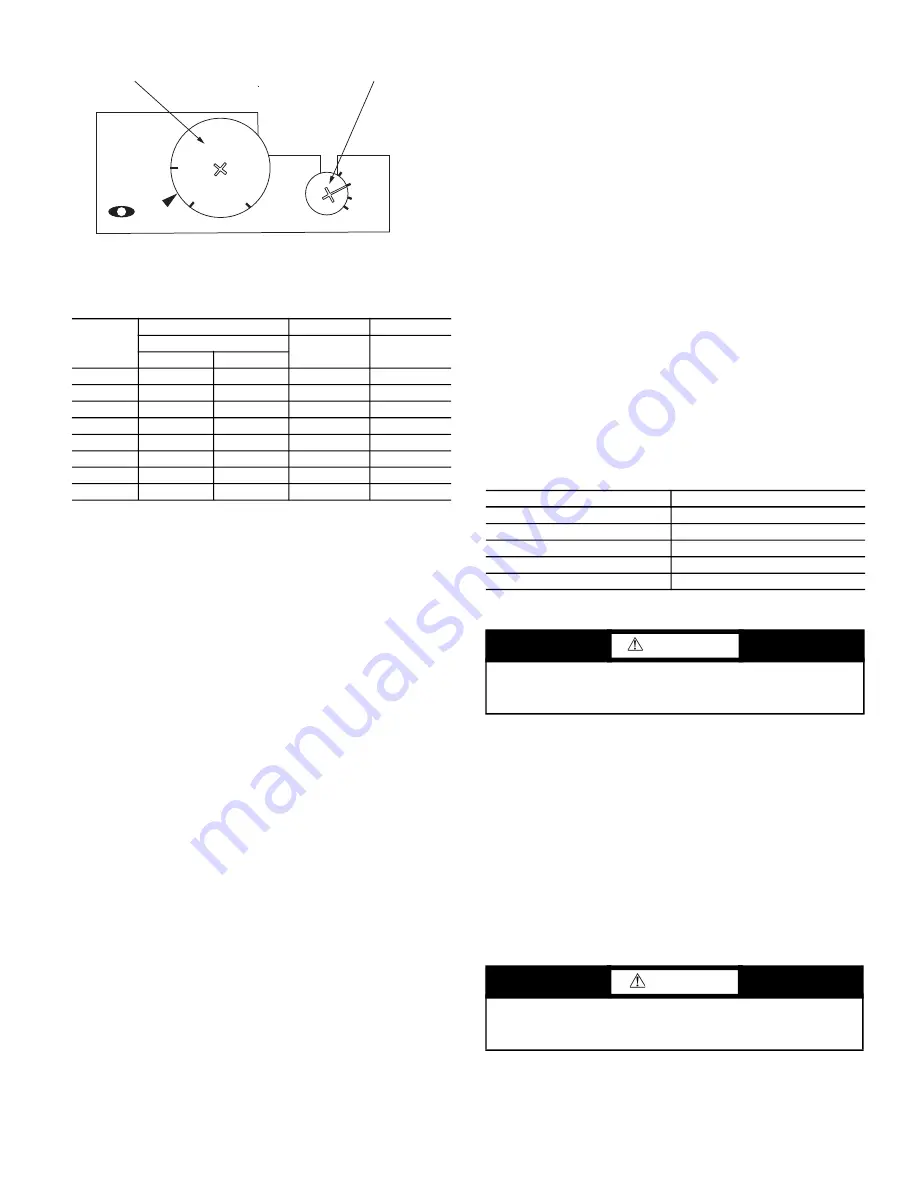

Fig. 24 — Motor Starter Setting

Table 21 — Evaporator and Condenser

Motor Starter Settings

MAINTENANCE

Cleaning

The unit should be thoroughly cleaned inside and out. Frequency

of cleaning will depend on unit location and area conditions.

Drains must be kept free of dirt and trash. Coils can be cleaned

with a stiff brush or vacuum cleaner. Coil can be reached through

access panels.

Inspection

Check coil baffles for tight fit to prevent air from bypassing the

coil. Check panels for air leakage, particularly those sealing the

fan and coil compartments. Check for loose electrical connections,

proper refrigerant charge, and refrigerant piping leaks.

Air Filters

Air filters may be installed on the condenser air inlet. Air filters

should be replaced or cleaned on a regular basis depending on

how dirty the operating environment is. Failure to clean air filters

regularly will result in loss of unit performance and possible nui

-

sance tripping of the high-pressure switch.

Condensate Drain

The drain pan and trap should be cleaned at least twice per year.

After cleaning, test the condensate drain for proper operation by

pouring a bucket of water into the condensate drain pan. The water

should flow out immediately and evenly.

Checking System Charge

NOTE: Condenser and evaporator airflow must be properly set

before checking system charge.

The 50XCA units are shipped with full operating charge. If re

-

charging is necessary:

1. Insert thermometer bulb in insulating rubber sleeve on liquid

line near filter drier. Use a digital thermometer for all tem

-

perature measurements. DO NOT use a mercury or dial-type

thermometer.

2. Connect refrigerant pressure gage to discharge line near com

-

pressor.

3. After unit condition have stabilized, read head pressure on

discharge line gage.

4. NOTE: Operate unit a minimum of 15 minutes before check

-

ing charge.

5. From standard Pressure-Temperature chart for R-410A, find

equivalent saturated condensing temperature.

6. Read liquid line temperature on thermometer; then subtract

from saturated condensing temperature. The difference

equals subcooling temperature.

7. Compare the subcooling temperature with the normal tem

-

perature listed in Table 22. If the measured liquid line tem

-

perature does not agree with the required liquid line

temperature, ADD refrigerant to raise the temperature or

REMOVE refrigerant (using standard practices) to lower the

temperature (allow a tolerance of ± 3°F).

Example:

Head pressure (from gage)416.4 psig

Saturated condensing temp (from chart)120°F

Liquid line temp (from thermometer)100°F

Subcooling (by subtraction)20°F

Table 22 — Subcooling Temperature

*Saturated condensing temperature at compressor minus liquid line tem-

perature.

NOTE: Do not vent or depressurize unit refrigerant to atmosphere.

Remove and recover refrigerant following accepted practices.

Access Panel Removal

TOP PANEL

Remove 3 to 6 screws, pull out panel, and remove.

CONTROL PANEL

Remove 4 screws and remove the panel.

BOTTOM PANEL

Remove 3 to 6 screws in bottom panel and lift up to remove the

panel.

Evaporator-Fan Motor Removal

NOTE: Motor power wires need to be disconnected from control

box terminals before motor is removed from unit.

HP

208-230 V

460 V

575 V

FLA

FLA

FLA

208V

230V

0.50

1.8

2.2

1.1

0.9

0.75

2.5

2.6

1.3

1.0

1.00

3.4

3.0

1.5

1.1

1.50

4.6

4.2

2.1

1.6

2.00

6.0

5.6

2.8

2.1

3.00

9.2

8.6

4.3

3.4

5.00

14.5

13.6

6.8

5.4

7.50

21.5

19.4

9.7

7.5

1.9

1.6

1.3

M

M-O

A-O

A

RESE

T-

O

CLASS 20

TEST

OVERLOAD SETPOINT WHEEL

MOTOR OVERLOAD RESET WHEEL

UNIT 50XCA

SUBCOOLING*

06

20°

08

17°

12-14

21°

16

18°

24

25°

WARNING

To prevent personal injury, wear safety glasses and gloves

when handling refrigerant. Do not overcharge system — this

can cause compressor flooding.

CAUTION

Before attempting to remove fan motors or motor mounts,

place a piece of plywood over evaporator coils to prevent coil

damage.