9

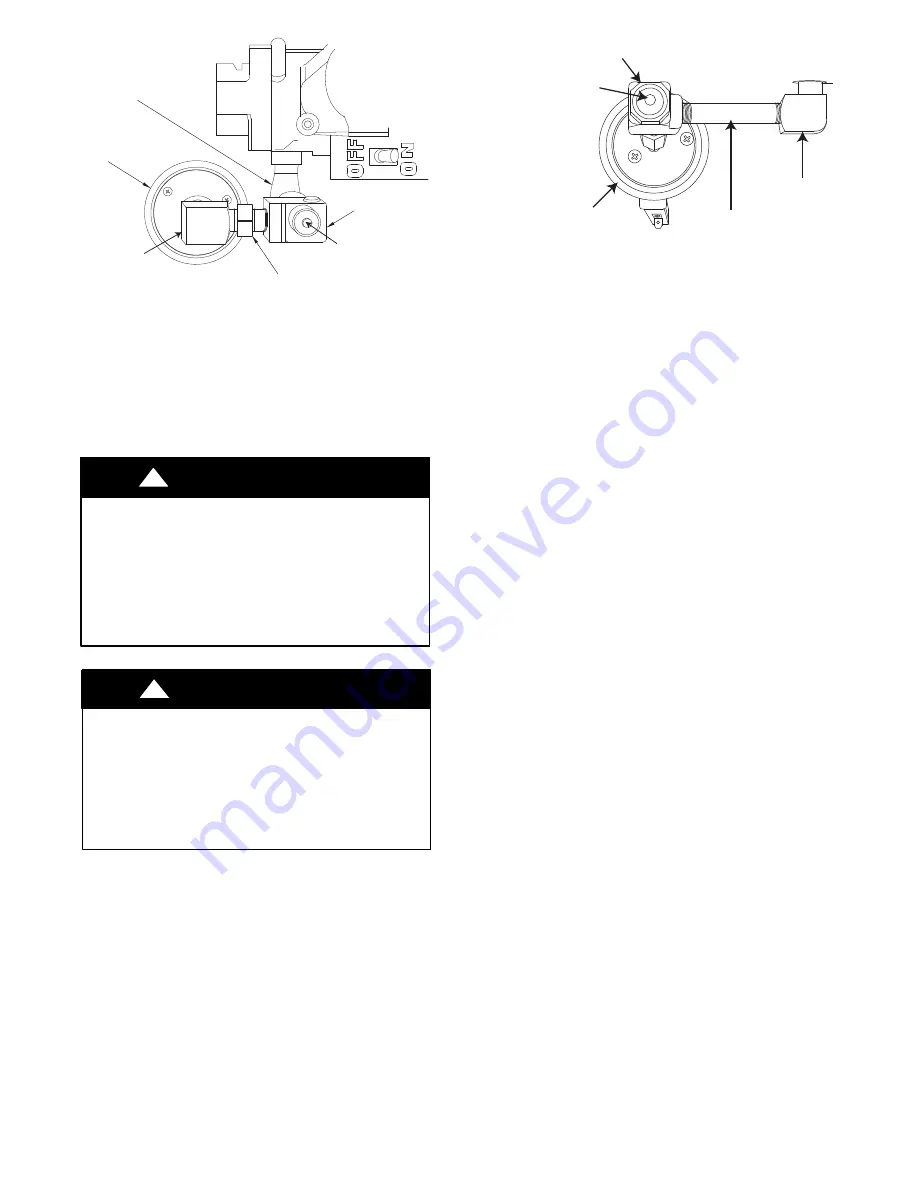

Brass Street Tee

Brass Hex Nipple

Brass Street 90

Low Gas Pressure Switch

Black Iron Street 90 Pointing

Inlet Pressure Tap with

A11367

Fig. 10 -- LGPS for 14--3/16 (360 mm) Casing or When Vent

Passes Between Inducer and Burner Assembly

NOTE

: Use pipe dope approved for use with Propane gas.

2. Apply pipe dope sparingly to the 1/8--in. NPT pipe plug

(provided in kit) and install in the 1/8--in. tapped inlet--

pressure tap opening in the gas valve. DO NOT over--

tighten. Check for gas leaks after gas supply has been

turned on.

FIRE AND EXPLOSION HAZARD

Failure to follow this warning could result in personal injury

and/or death.

NEVER test for gas leaks with an open flame. Use a

commercially available soap solution made specifically for

the detection of leaks to check all connections. A fire or

explosion may result causing property damage, personal

injury or loss of life.

!

WARNING

RISQUE D’EXPLOSION ET D’INCENDIE

Le fait de ne pas suivre cet avertissement pourrait entraîner des

dommages corporels et / ou la mort.

Ne jamais examiner pour les fuites de gaz avec une flamme

vive. Utilisez plutôt un savon fait specifiquement pour la

détection des fuites de gaz pour verifier tous les connections.

Un incendie ou une explosion peut entrainer des dommages

matériels, des blessures ou la mort.

!

AVERTISSEMENT

Casings Wider Than 14 3/16-in. (360 mm) /Vent Does Not

Pass Between Inducer and Burner Assembly

If the vent pipe does not pass between the inducer and burner

assembly, or the furnace is wider than a 14 3/16-in. (360 mm)

wide casing, the switch may have been installed as follows. (See

Fig 11.)

Brass Street

Brass Nipple

Low Gas Pressure Switch

Inlet Pressure Tap

with Plug

Brass Street Tee

A11517

Fig. 11 -- LGPS for Casing Wider Than 14--3/16 (360 mm)

and Vent Does Not Pass Between Inducer and Burner

Assembly

1. Remove low gas pressure switch, brass street 90

_

elbow,

brass Hex nipple, brass Tee and brass nipple from the gas

valve inlet pressure tap. (See Fig 11.)

NOTE

: Use pipe dope approved for use with Propane gas.

2. Apply pipe dope sparingly to the 1/8--in. NPT pipe plug

(provided in kit) and install in the 1/8--in. tapped inlet--

pressure tap opening in the gas valve. DO NOT over--

tighten. Check for gas leaks after gas supply has been

turned on.

INSTALL MANIFOLD

1. Align the orifices in the manifold assembly with the sup-

port rings on the end of the burner.

2. Insert the orifices in the support rings of the burners. Man-

ifold mounting tabs should fit flush against the burner box

NOTE

: If manifold does not fit flush against the burner box, the

burners are not fully seated forward. Remove the manifold and

check burner positioning in the burner box assembly.

3. Attach the green/yellow wire and ground terminal to one

of the manifold mounting screws.

4. Install the remaining manifold mounting screws.

5. Connect the wires to the flame sensor and hot surface ig-

niter.

6. Connect the connector harness to gas valve.

7. Rewire unit low pressure switch (LPS) as follows:

a. Trace one of the orange wires previously disconnected

from the LGPS back to the NO terminals of the LPS.

b. Trace the other orange wire previously disconnected

from the LGPS back to its splice connection with the yel-

low wire of the furnace wire harness. Disconnect and dis-

card this orange wire and the splice connection.

c. Connect the yellow wire of the furnace wire harness (see

“b” above) to the NO terminal of the LPS.

d. Refer to the furnace wiring diagram to ensure proper loca-

tion of wires.

NOTE

: Use only Propane-resistant pipe dope. DO NOT use

Teflon tape.

8. Insert the gas pipe through the grommet in the casing. Ap-

ply a thin layer of pipe dope to the threads of the pipe and

thread the pipe into the gas valve.

NOTE

: Use a back-up wrench on the gas valve to prevent the

valve from rotating on the manifold or damaging the mounting to

the burner box.

9. With a back-up wrench on the inlet boss of the gas valve,

finish tightening the gas pipe to the gas valve.

10. Turn gas on at electric switch on gas valve.