24

Evaporator

30XW-VZE/30XWHVZE chillers use a flooded multi-tube

evaporator. The water circulates in the tubes and the refrigerant

is on the outside in the shell. One vessel is used to serve both

refrigerant circuits. There is a center tube sheet which separates

the two refrigerant circuits. The tubes are 3/4” diameter copper

with an enhanced surface inside and out. There is just one water

circuit with two water passes.

The evaporator shell has a polyurethane foam thermal insulation

and a water drain and purge.

It has been tested and stamped in accordance with the applicable

pressure codes. The maximum standard relative operating

pressure is 2100 kPa for the refrigerant side and 1000 kPa for the

water-side. These pressures can be different depending on the

code applied. The water connection of the heat exchanger is a

Victaulic connection.

The products that may be added for thermal insulation of the

containers during the water piping connection procedure must be

chemically neutral in relation to the materials and coatings to which

they are applied. This is also the case for the products originally

supplied by Carrier.

Condenser and oil separator

The 30XW-VZE/30XWHVZE chiller uses a heat exchanger that

is a combination condenser and oil separator. It is mounted below

the evaporator. Discharge gas leaves the compressor and flows

through an external muffler to the oil separator, which is the upper

portion of the heat exchanger. It enters the top of the separator

where oil is removed, and then flows to the bottom portion of the

vessel, where gas is condensed and subcooled. One vessel is

used to serve both refrigerant circuits. There is a center tube sheet

which separates the two refrigerant circuits. The tubes are 3/4” or

1” diameter internally and externally finned copper tubes.

There is just one water circuit with two water passes. For the Heat

Machine units the condenser shell can have a polyure-thane foam

thermal insulation (option 86) and a water drain and purge.

It has been tested and stamped in accordance with applicable

pressure codes. The maximum standard relative operating

pressure is 2100 kPa for the refrigerant side and 1000 kPa for the

water-side. These pressures can be different depending on the

code applied. The water connection of the heat exchanger is a

Victaulic connection.

9.7 - High Pressure SRMCR safety loop

9.7.1 -

General description

The unit is equipped with a high pressure safety loop, known as

the SRMCR (Safety-Related Measurement Control and

Regulation) loop, comprising

-2 high pressure switches (HPS) that require resetting with a

tool at the outlet for each compressor called PZHH

-The speed regulator which supplies the compressor is

equipped with the Safe Torque Off (STO) function.

Refer to the wiring diagram and the nomenclature for the machine

(references).

This SRMCR device is designed in accordance with standard EN

61508 for SIL (safety integrity level): 2.

Demand mode: bottom and top.

The mission time is 20 years.

Periodic testing: the test must be performed at least once a year

during the normal periodic pressure test. Refer to the description

in section 11.9.

9.7.2 -

Description of operation and resetting

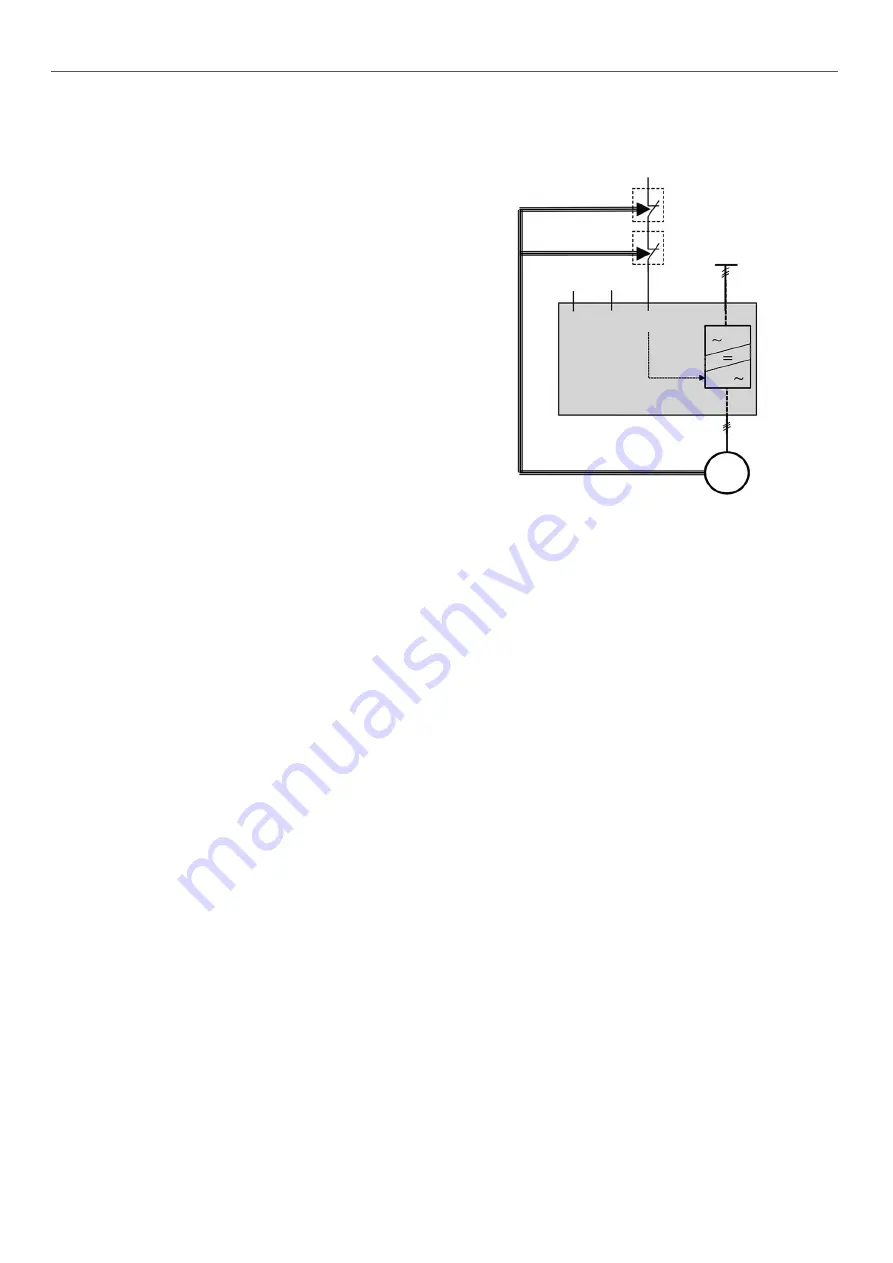

The image below is intended to illustrate the operating description:

refer to the detailed machine drawing for the precise wiring

diagram.

HPS SP_F

Pressure increase

Direction of operation

Pressure increase

Direction of operation

Normal

start-stop

Com bus for

frequency

setting

STO Input

PLd- SIL2

Compressor

06T

HPS SP_F

GS_1 drive

400Vac

HPS :

High pressure switch SP1F(A)/SP2F(A)

GS_1 :

Power drive for compressor GSA1/GSB1

During normal operation, the speed regulator supplies and controls

the compressor once the control signal is received via the digital

on-off input (normal on-off) and the communication bus (setting

the frequency).

When one of the HPS sensors opens, the STO (Safe Torque Off)

digital input opens, which instantly suppresses the control

command for the thyristors which manage the supply for the

compressor, independently of the on-off commands and

frequencies: the compressor is no longer supplied and stops

immediately.

9.7.3 -

Verification in case of a safety device failure

If the unit operating pressure appears to have been exceeded at

some point (for example, after the relief valves have been opened),

the unit must be stopped immediately.

The safety loop unit must pass all the periodic verifications before

any restart is possible.

If the test reveals malfunctions likely to have caused overpressure

within the machine, a complete check of all the pressure equipment

must be performed to check their mechanical integrity.

9.7.4 -

Restarting after high pressure is detected

After overpressure is detected, it is necessary to manually reset

the switched HPS. A blunt tool with a diameter of less than 6 mm

must be used for this.

9 - MAJOR SYSTEM COMPONENTS AND OPERATION DATA