5 - AIR CONNECTIONS

Air quality:

Comfort units are not designed to control the humidity of outside

air. Fresh air handling must be provided by an independent

system in accordance with accepted engineering practice (see

CARRIER’s ranges of air handling units).

Warning

: on all models with plenums, all collars must be

connected. None must be capped, either at the supply or return

air.

Fresh air knockout

The fresh return air must be taken from air pretreated by an

air handling unit which complies with European regulation No.

1253/2014.

Under no circumstances may fresh air from outdoors be

connected directly to the unit.

Fitting and adjusting fresh air collars (accessory)

- Remove the washer from the pre-punched panel by

cutting the attachment points.

- Fasten the collar with or without controller using the 4

screws supplied.

- Either remove or leave on the shims needed to obtain the

desired flow rate. The flow rate ranges are given on the

label on the casing.

- 2 shims for minimum flow, 1 shim for medium flow, no

shims for maximum flow.

- The pressure difference must be between 50 and 100 Pa

in order to obtain the desired flow rate.

- Maintain the controller in the “BAS” (down) position.

6 - HYDRAULIC CONNECTIONS

The coils are fitted with a ‘female’ hydraulic connection, a turning

nut with a flat face (1/2” and 3/4” in diameter, depending on the

size) and an O ring (supplied with the unit), an air bleed valve

and a drain valve.

Water always flows into the bottom of the coil and exits at the

top.

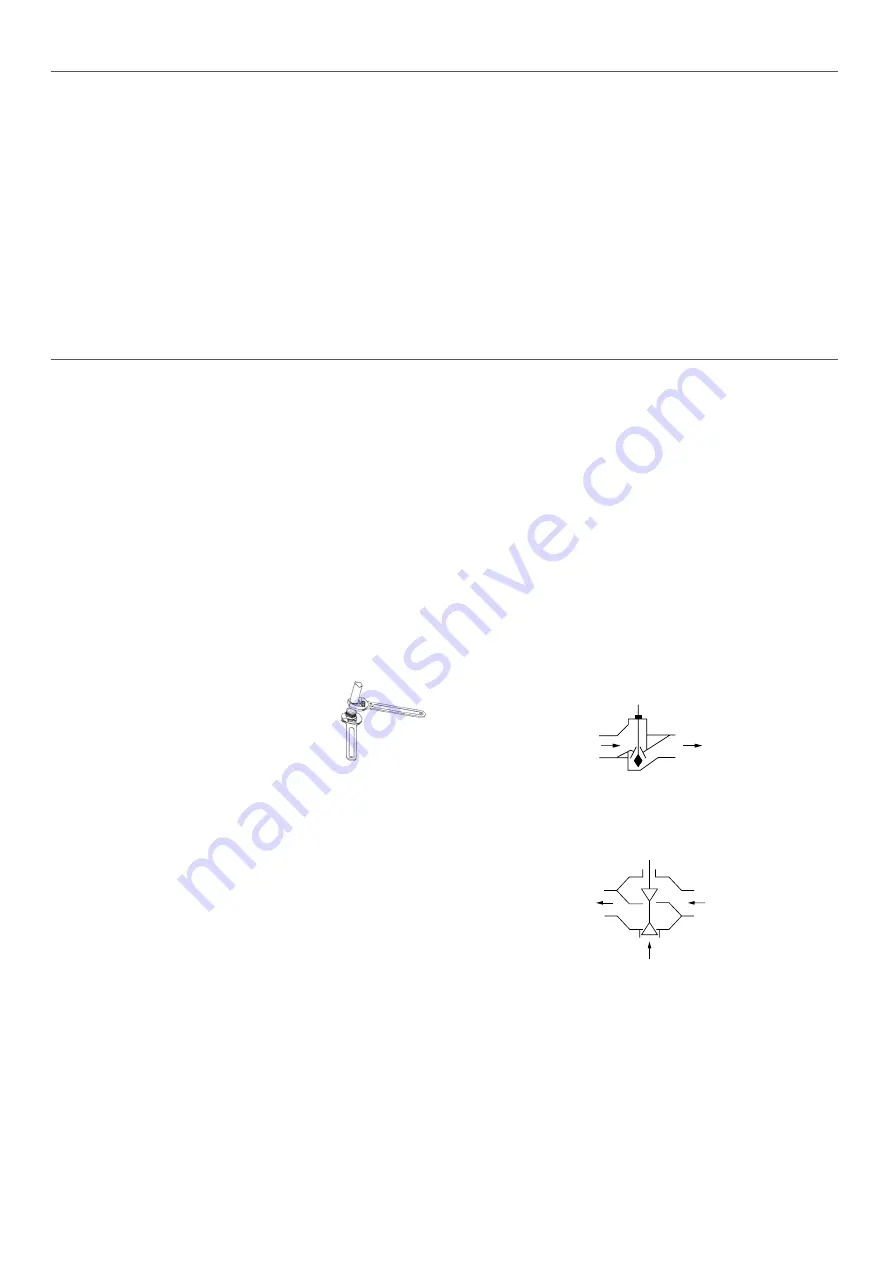

To install a control valve with a flat face

(fig. 8)

:

l

Two-way valve:

screw the valve and gasket provided directly

on the hydraulic connections at the coil intake (at the bottom):

- 2-way valve, 2 pipe version (fig. 8a)

- 2-way valve, 4 pipe version (fig. 8b)

l

Three-way valve with integral bypass:

add the copper pipe

before fitting the valve:

4-way valve, 2 pipe version (fig. 8c)

4-way valve, 4 pipe version (fig. 8d), onto the coil cooling

connection.

Installation

l

To avoid damaging this coupling or the

CARRIER

valve, never tighten to more than

1.8 daN.m of torque. Use 2 spanners, one to

hold and the other to tighten, to ensure the

valve connection seal is maintained.

Always fit the valve in the right direction. The direction of flow for

these

CARRIER

valves should be

A

>

AB

(A being connected

to the coil and AB to the hydraulic network). The maximum

allowable differential pressure for our valves (open or closed) is

100 kPa.

CARRIER

recommends not exceeding 60 kPa.

Recommendations on hydraulic connections

The design of a hydraulic network is crucial to the correct

operation of the system. Drain valves should therefore be placed

at the appropriate points and in sufficient number. In addition,

strainers should be fitted, as well as drains at circuit high points,

balancing tees on each unit and, if necessary, discharge valves.

Pressure safety:

The installation must be protected against any risk of pressure

surges. Special care must be taken to protect against the risks

linked to expansion of the energy transfer fluid and to the total

hydrostatic pressure.

Filtration:

An efficient filtration system (recommended mesh size of 0.5

mm) should be fitted on the supply water and return water lines.

Flushing:

The system must be flushed completely and filled with treated water

to prevent the build-up of scale or sludge in the circuit. When flushing

the system, open the valve on the unit to prevent any sludge or scale

entering the coil:

l

Thermostatic valves: remove the servomotor to fit the cap,

which will cause pressure to be applied to the shaft, thereby

opening the passage, or request that the valve is opened by

the control.

A

AB

l

3-position modulating valves: if the power has not yet been

switched on, the valve will be open by default. If the control

has already been powered up, remove the servomotor to

release the rod and open the passage.

AB

A

B

Filling:

Drain the coils during system start-up.

12

Содержание 42NC

Страница 2: ...2...

Страница 5: ...1 2 3 4 5 6 7 8 9 10 11 12 3 a c a b 4 100 mm mini a b 5 6 5...

Страница 6: ...7 a 8 b c 6...

Страница 7: ...d 09 a 10 c b a d e 7...

Страница 8: ...11 b a e c d a b c 12 a b 13 b 14 a c d e 8...

Страница 9: ...b a b a 15 16 a 17 b c d 18 e 9...

Страница 18: ...18...

Страница 19: ...19...