Table 3 — Fitting Requirements (cont)

UNIT

ACCESS

HOLE NO.*

CONNECTION

TYPE

CIRCUIT

FITTINGS REQUIRED†

(in.)

40RMS

028, 034

5

Supply

Lower

2

1

⁄

8

Long Radius Elbow

2

1

⁄

8

Nipple, 3

1

⁄

2

L

2

1

⁄

8

Long Radius Elbow

6

Return

Lower

2

1

⁄

8

Long Radius Elbow

2

1

⁄

8

Nipple, 3 L

2

1

⁄

8

Long Radius Elbow

7

Return

Upper

2

1

⁄

8

Long Radius Elbow

2

1

⁄

8

Nipple, 6

7

⁄

8

L

2

1

⁄

8

Long Radius Elbow

8

Supply

Upper

2

1

⁄

8

Long Radius Elbow

2

1

⁄

8

Nipple, 11

7

⁄

8

L

2

1

⁄

8

Long Radius Elbow

40RM

034

1

Suction

Lower

1

3

⁄

8

Street Elbow

1

3

⁄

8

Nipple, 3 L

1

3

⁄

8

Long Radius Elbow

2

Liquid

Lower

5

⁄

8

Street Elbow

5

⁄

8

Nipple, 7

3

⁄

4

L

5

⁄

8

Long Radius Elbow

3

Liquid

Upper

5

⁄

8

Street Elbow

5

⁄

8

Nipple, 18

1

⁄

2

L

5

⁄

8

Long Radius Elbow

4

Suction

Upper

1

3

⁄

8

Nipple, 4

3

⁄

16

L

1

3

⁄

8

Long Radius Elbow

1

3

⁄

8

Nipple, 19

1

⁄

4

L

1

3

⁄

8

Long Radius Elbow

*See Fig. 4 for access hole location by number.

†Fittings are listed in order from header or tee stub connection out to access hole in corner support post.

Chilled Water Piping —

See Tables 1C and 1F for

chilled water connection sizes. For ease in brazing, it is rec-

ommended that all internal solder joints be made before unit

is placed in final position.

Knockouts are provided in the unit corner posts for 40RM

and 40RMQ refrigerant piping; additional field-fabricated ac-

cess holes are required for 40RMS chilled water piping. See

Fig. 4, which lists recommended knockouts and access holes

to use for each 40RMS unit size.

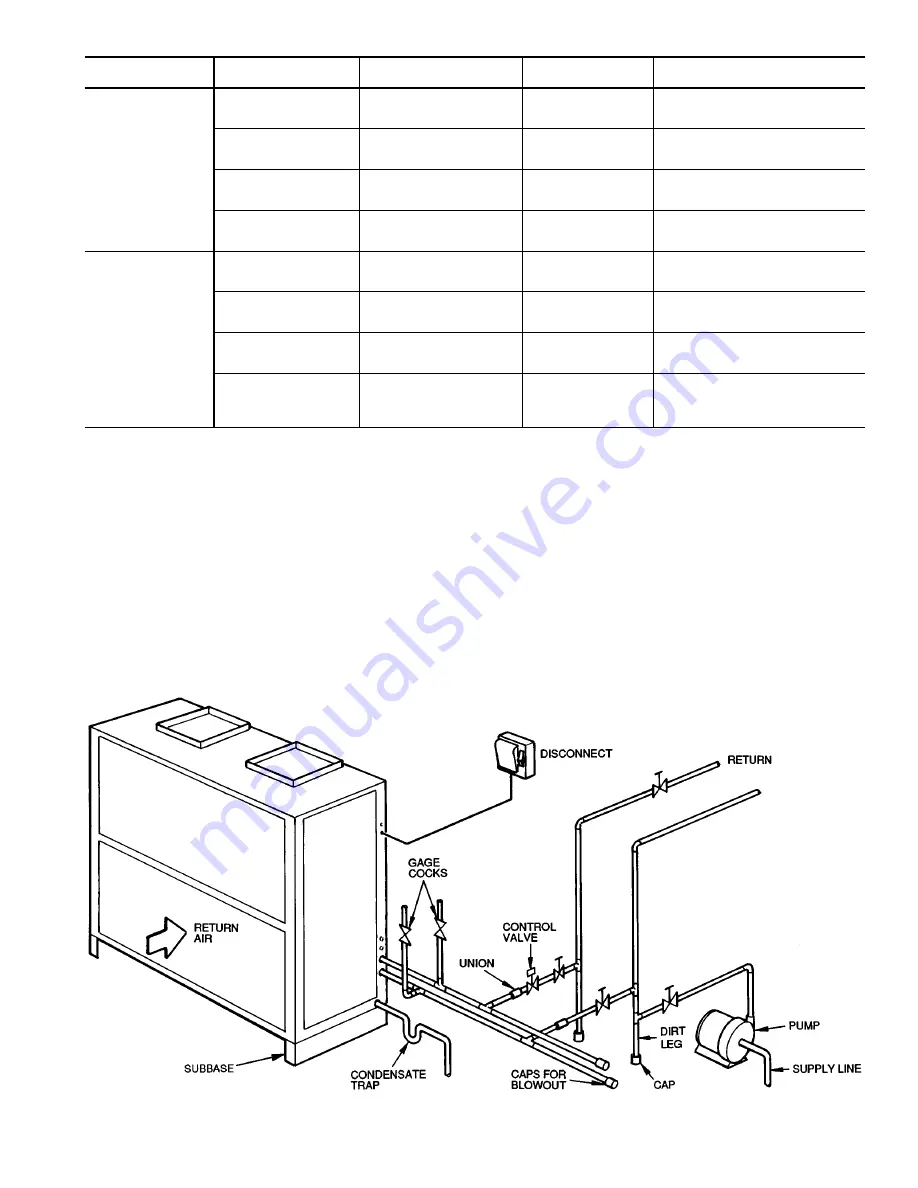

To size, design, and install chilled water piping, consult

the Carrier System Design manual. See Fig. 9 for an ex-

ample of a typical installation. Recommended fittings are listed

in Table 3.

To access 40RMS coil vents and drains, remove the unit

side panel over the coil header. Vent and drain plugs are on

the top and bottom of header, respectively. See the Service

section for information on preventing coil freeze-up during

winter.

Fig. 9 — Typical 40RMS Chilled Water Piping

17