Step 3

Dehydrate and Recharge Circuit

W h e n piping has been completed, leak test the assembly

and replace the filter drier, or core(s) for circuit no. 1.

On single-compressor chillers

15,025 and 030

for 60 Hz, 020,025 for 50 Hz; 30GT) the filter drier itself

must be replaced.

After core (or drier) replacement, evacuate, dehydrate

and recharge the circuit. Procedures for evacuation,

dehydration and charging are detailed in Carrier Stand-

ard Service Techniques Manual, Chapter 1, Refrig-

erants, Sections 6 and 7.

Step 4

Install Control Wiring

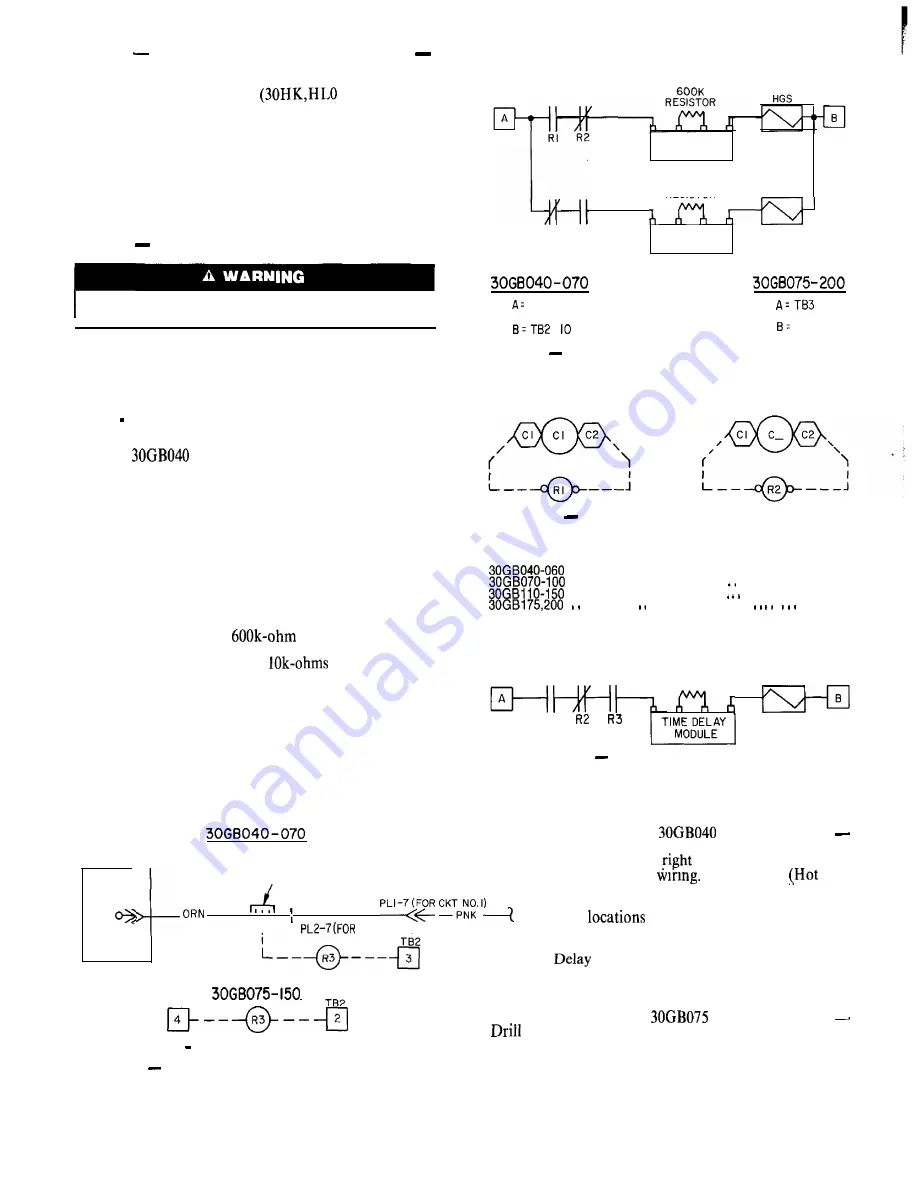

TIME DELAY

MODULE

6 0 0 K

RESISTOR

HGS

RI R2

TIME DELAY

MODULE

Be sure all power to the unit is off before proceeding.

1

Wires between field-installed components and unit

control box must be enclosed in conduit.

Wire size is

no. 16 AWG minimum. Wire-end terminals required on

field wires are indicated in the Combined Legend for

Fig. 3 8.

UNITS

THROUGH 070 FLOTRONIC (See

Fig. 3.)

Control logic allows the hot gas bypass to be

energized only on the first stage of capacity.

A unit with 2 unloaders has the automatic lead/lag

feature which allows starting of either circuit, and

thus must have 2 hot gas bypass packages, one per circuit

(see Fig. 4).

On the 040-060 units, R3 should energize with com-

pressor no. 2. On the 070 unit. R3 energizes with com-

pressor no. 3. In both instances, it is the lead compressor

on circuit no. 2 (see Fig. 5.)

The time delay module must be set for a one-minute

delay by connecting a

resistor between the

center terminals of the module (see Fig. 6). (One second

of time delay results from each

of resistance.)

NOTES:

1. Relays R 1 and R2 apply to all units.

2. R3 applies only to units with a single unloader. Units

with no unloaders or 2 unloaders do not require R3.

3. 30GB 175 and 200 units do not use unloaders.

RELAY

BOARD

J 6

FIELD

SPLICE

,

,

PIN 4

I

CKT NO.21

T B 4

NOTE: 3063175,200 R3 DOES NOT APPLY.

Fig. 3

R3 Coil Wiring (R3 used only with

units having a single unloader)

T B 2 4

c l

I

c l

q

T B 2 2

c l

Fig. 4

Hot Gas Solenoid Wiring, Units with

No Unloaders or

Two

Unloaders

Fig. 5

RI and R2 Coil Wiring, All Units

Connect R2 in parallel with lead compressor in circuit 2:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Comp 2

. . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . Comp 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Comp 4

. . . . . . . . , . . . . . . . . . . . . . . . . . . .

Comp 5

(Refer to Fig. 2 for compressor locations.)

RI

Fig. 6

Hot Gas Solenoid Wiring,

Single Unloader Units

6 0 0 K

RESISTOR

HGS

FLOTRONIC’” UNITS,

THROUGH 070

Drill a hole to accommodate a standard conduit fitting

in bottom of control box at

end, adjacent to existing

entrance hole for control

Locate HGR

Gas

Bypass Relay) in right side of control box adjacent to

existing relays. Using the HGR base as a template, mark

mountmg hole

and drill appropriate hole. Run

conduit from the bypass valve to the control box and wire

relays into control circuit as shown in Fig. 4. Relays

and Time

Module should be installed in the upper

left corner of the control box, above the transformer.

FLOTRONIC UNITS,

THROUGH 200

2 holes in the bottom right of the control box, next

to the compressor conduit holes, to accommodate stand-

ard conduit fittings. Run conduit from the bypass valve

to the control box and wire relays into control circuit

as shown in Fig. 4.