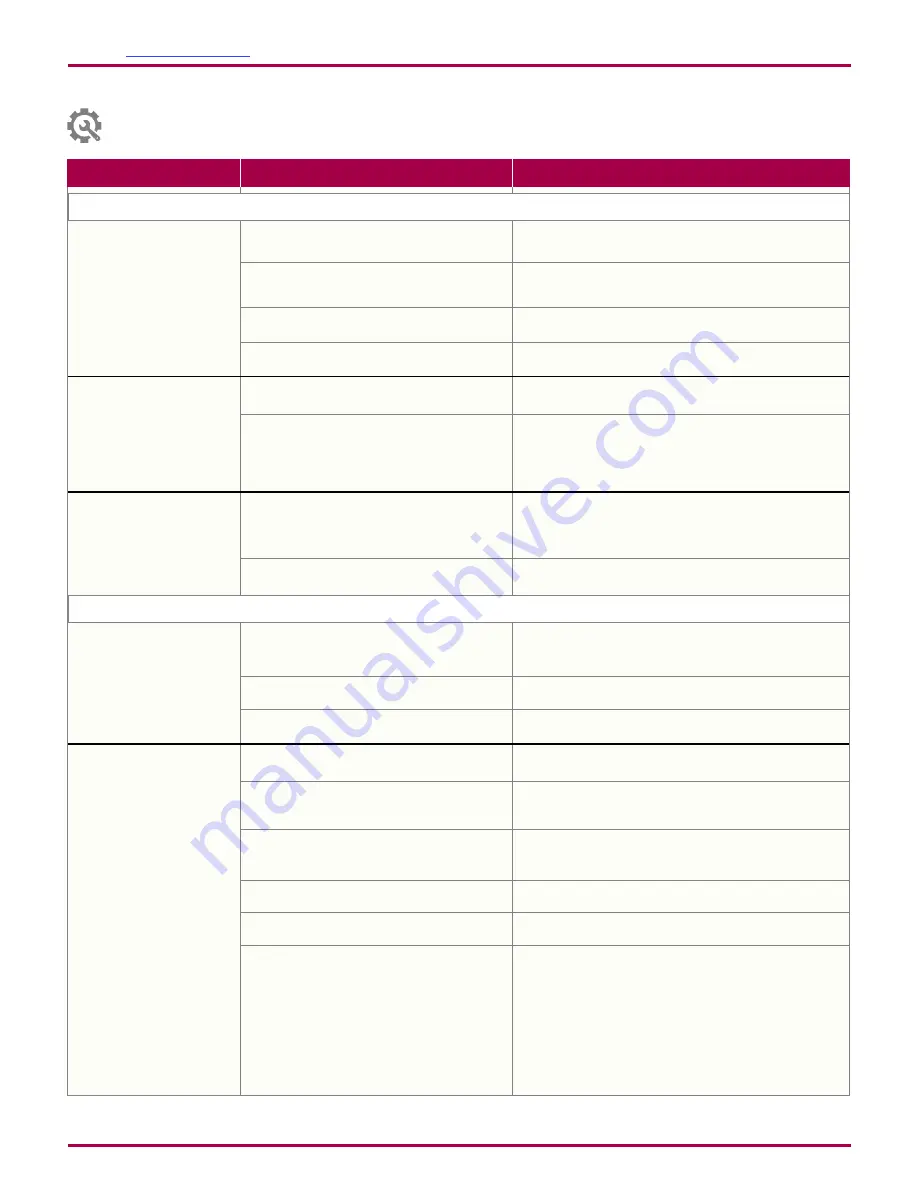

General Problem

Possible Cause

Solution

TROUBLESHOOTING GUIDE

(Cont.)

(Continued On Next Page)

INADEQUATE DELIVERY

Pattern Will Not

Shape

Clogged or faulty fan air valve

Air passages in applicator or air

line clogged

Worn, faulty, or clogged air cap

Barrel restrictor missing

Clean, repair, or replace.

Blow out, clean, or replace.

Clean or replace.

Replace barrel restrictor.

Pattern Heavy At

One End

Clogged or faulty air cap

Clogged or faulty fluid nozzle

Clean or replace.

Clean or replace.

Extremely Heavy

Spitting or Severely

Deformed Pattern

Wrong air cap/fluid nozzle

combination

Faulty air cap

Ensure proper fluid nozzle/air nozzle pressure

reducer combinations (see“Fluid Nozzle Tables” in

the “Installation” section).

Replace.

Air passages in applicator or air line

clogged

Inadequate air source

Paint in air passage

Blow out.

Increase pressure, flow capacity.

Clean and blow out.

Air

Fluid

Clogged or faulty fluid nozzle

Clogged passages in applicator fluid

tube or fluid line

Insufficient needle/electrode travel

Low fluid supply pressure

Clogged fluid filter

Clogged or obstructed valve or fluid

regulator

Flush or replace.

Flush.

Adjust (see “Trigger Adjustment Nut Dimension

Figure” in the “Maintenance” section).

Increase.

Clean or replace.

Clean as required or replace.

DEFECTIVE SPRAY PATTERN

AH-06-01-R17 (08/2019)

51 / 79

www.carlisleft.com

MAINTENANCE

EN