AIR CAP

Removal

1. While holding the barrel with one hand, loosen the

retaining nut using the other hand.

2. Unscrew the retaining nut completely and remove the

air cap.

Cleaning and Inspection

1. Use a suitable solvent to clean the air cap. (Refer

to "Suitable Solvents for Cleaning Vector R90/70

Applicators" in the "Maintenance" section.)

2. Examine the air cap for damage to the air horns, face,

and any air passages. If any of these areas are damaged

or worn, the air cap should be replaced.

Reinstall

1. Check the fluid nozzle to ensure that it is tightly screwed

into the barrel.

2. Place the air cap over the electrode wire of the needle/

electrode and set it onto the fluid nozzle.

3. Place the retaining nut over the air cap and begin

screwing it onto the barrel.

4. Before securing the retainer nut to the barrel, position

the air cap for the desired spray pattern position.

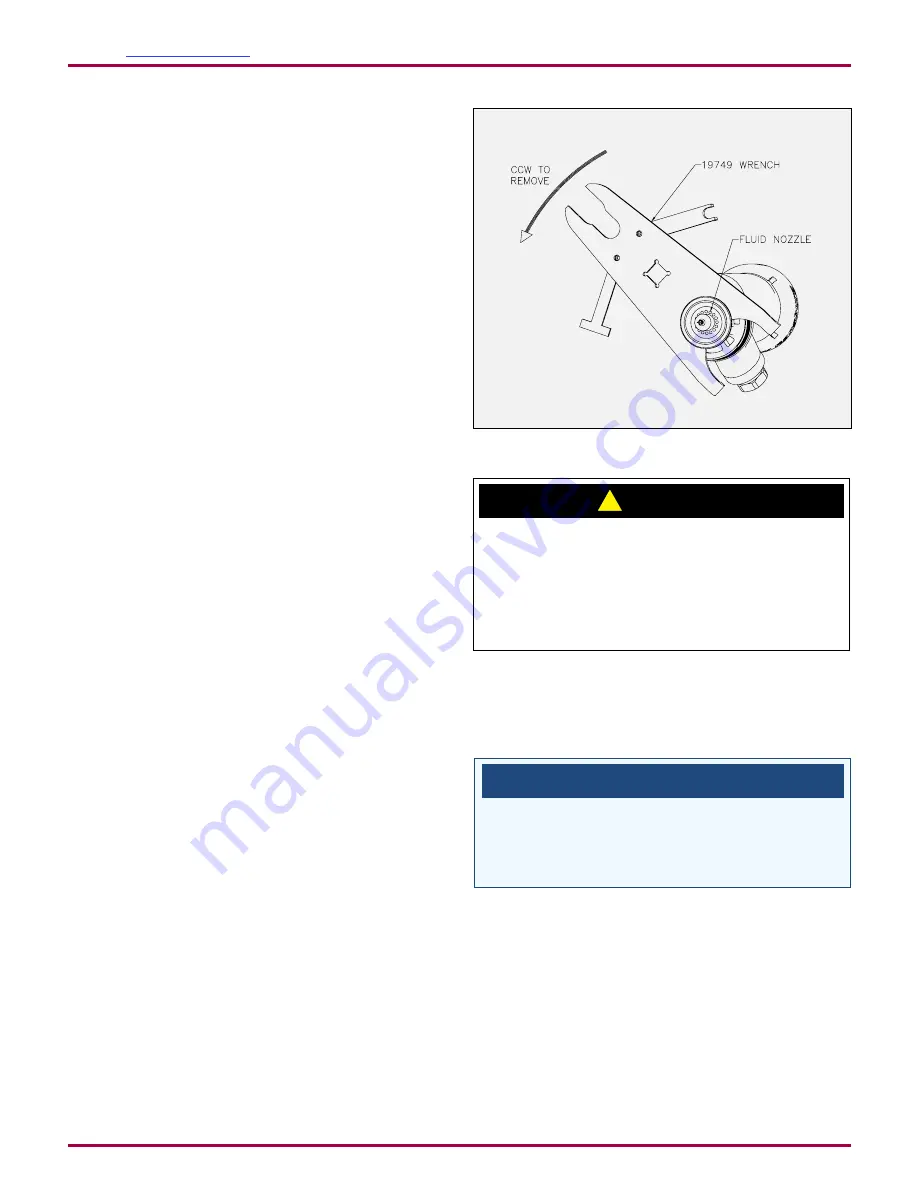

FLUID NOZZLE

(Refer to Figure 18)

Removal

1. Remove the air cap from the applicator (refer to "Air

Cap - Removal" in the "Maintenance" section).

2. Tilt the applicator forward and pull the trigger to make

sure that all fluid in the applicator is drained out.

Figure 18: Removal of Fluid Nozzle

CAUTION

!

The applicator barrel

MUST

be tilted front down

to remove the fluid nozzle. Failure to do so may allow

paint to enter the air passages, thereby reducing air-

flow and damaging the applicator barrel. Applicators

may be flushed in lieu of tilting. However, they

MUST

be either flushed or tilted during nozzle removal!

NOTE

3. While holding the applicator assembly with the trigger

pulled back, remove the fluid nozzle with the open-end

of the special multi-purpose wrench.

To keep the needle/electrode from unscrewing

from the needle shaft, the applicator's trigger should

be actuated to pull the needle/electrode away from

the fluid nozzle.

Cleaning and Inspection

1. Use a suitable solvent to clean the fluid nozzle

2. Examine the fluid nozzle for damage to the air passages

and the fluid nozzle tip. Also, examine the needle seat

for damage or wear. If any damaged or any worn areas

are found, the fluid nozzle must be replaced.

AH-06-01-R17 (08/2019)

40 / 79

www.carlisleft.com

MAINTENANCE

EN