CAUTION

!

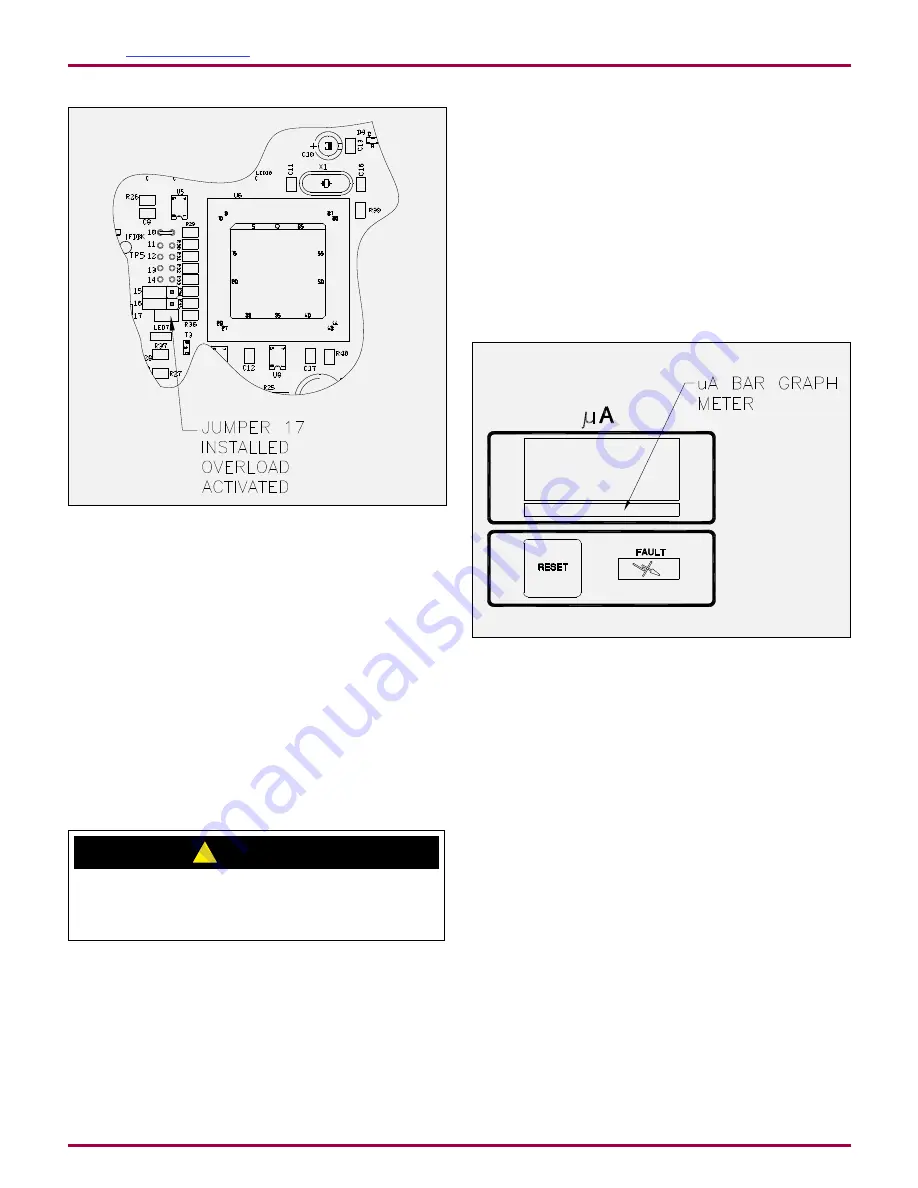

Figure 11: Jumper Location - Overload Activation

BASIC OPERATION

Triggering

High voltage is actuated by pulling the trigger to start the

flow of atomizing and fan control air through the applicator.

When the applicator is triggered, an air flow switch is ac-

tivated, the kV setpoint is displayed on the kV display, the

actual current draw on the µA display and the high voltage

light illuminates. Under the µA display is a bar graph meter

that illuminates according to the actual current draw.

Figure 12: µA Bar Graph Display

The green and yellow regions of the bar graph meter indi-

cate output current is in the optimum range for maximum

transfer efficiency. The red region of the bar graph indicates

high output current causing decreased transfer efficiency.

The display at the rear of the applicator also doubles as a

microamp bar graph meter when high voltage is on (see

Figure 13). Its function is similar to that of the control unit

bar graph display.

KV TEST JUMPER

To assist in testing and troubleshooting, a jumper (J8) has

been added to the main PC board. By covering (shorting)

both terminals of this jumper, the high voltage to the spray

applicator can be activated. Thus, for testing and trou-

bleshooting, high voltage output can be obtained without

the need to trigger air through the spray applicator. After

testing, the jumper must be repositioned so that it covers

only one terminal (open) or the high voltage will stay on

all the time. (See Figure 8 for location of test jumper J8.)

If jumper J8 is left covering (shorting) both termi-

nals, high voltage will be on whenever AC power is

turned on.

AH-06-01-R17 (08/2019)

33 / 79

www.carlisleft.com

OPERATION

EN