MTF 9/15

4.11 Stopping the Timer

To stop the timer at any time while it is running, change the

StAt

parameter to

OFF

. This is the

same as reducing

tmr

to zero. The controller then acts as though at has reached the end of the time

period.

4.12 End of Time Period

Modes 1 and 3: heating stops at the end of timing; the

m-A

parameter changes to

mAn

.

Modes 2 and 4: heating continues at the end of timing; the

m-A

parameter remains at

Auto

.

Mode 5: heating starts at the end of the timing period; the

m-A

parameter remains at

Auto

.

In modes 1 to 4 the alarm message

EnD

flashes on the display at the end of timing; the

StAt

parameter remains at run.

In mode 5 there is no

End

message; the

StAt

parameter changes to

OFF

at the end of timing.

4.13 Cancelling the Alarm

To acknowledge (cancel) the

EnD

alarm, press Page and Scroll together; the

StAt

parameter

changes to

OFF

.

Alternatively the alarm may be cancelled by directly changing the

StAt

parameter from

run

to

OFF

.

4.14 User Calibration

The controller is calibrated for life at manufacture against known reference sources, but there may

be sensor errors or other system errors. User calibration allows compensation for such errors, and

the 2132 allows for a user 2-point calibration. This setting is password protected to avoid

accidental alteration.

Page

to

iP

, scroll to

CAL.P

, and use Up

S

to alter the password. The password is

3

. If the correct

password is entered, the display shows

PASS

. Scroll to

CAL

and use

T

or

S

to observe the setting

FACt

(factory values, as manufactured) or

USEr

(user values). Change to

USEr

.

NOTE: before checking the calibration of the controller, or of the complete system, remember to

reset the 2132 to factory calibration values by setting the

CAL.P

parameter to

FACt

.

To enter a user calibration, scroll to each or the following parameters in turn and set the desired

values.

Pnt.L

low temperature for which an offset is to be entered

OFS.L

offset value for the low temperature

Pnt.H

high temperature for which an offset is to be entered

OFS.H

offset value for the high temperature

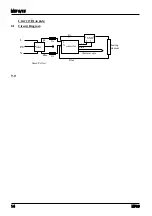

Example: the controller reads 3°C low at 400°C, and 5°C low at 1000°C. The parameter values

should be

Pnt.L

=

400

,

OFS.L

=

3

,

Pnt.H

=

1000

,

OFS.H

=

5

.

Negative or positive values can be entered: if

the controller is reading high, negative offsets

would be appropriate.

Fig 4 gives a graphical representation of the 2-

point calibration.

5.0

MF09

9