output will usually burn-off any window deposits left by tarry or wet

fuels. After a period of use tiny hairline cracks may appear on the

window, this is not a fault and will not increase the risk of

breakage but is a characteristic of the toughest and most heat-

resistant material currently available.

OPENING THE DOOR

This stove is designed to be operated only

with the door closed. Open the door slowly when refuelling or de-

ashing to minimise fume emission.

FUELS

There is no 'perfect' fuel, so we strongly recommend that you try a

selection of fuels (or mixtures) to find which suits you best. Do

avoid dusty materials like sawdust, they can burn far to violently.

SMOKE CONTROL:

In certain areas special rules apply to reduce

smoke nuisance. Check with your local authority.

WOOD

only emits as much carbon to the atmosphere as the tree

took in when growing, so wood is considered the 'carbon neutral'

fuel. When wood is cut down its cells are full of water. Burning

such wet or 'green' wood wastes heat in making steam and

produces flammable, acidic tars which will cling to, and can

damage, your stove and chimney. Logs should be split lengthways

and dried for at least a year. The fine, white residue produced

when wood burns is not ash, but the remains of cell walls which

can burn if kept hot enough, so don't de-ash a wood fire until

absolutely

necessary.

Minimise smoke emission from wood by:

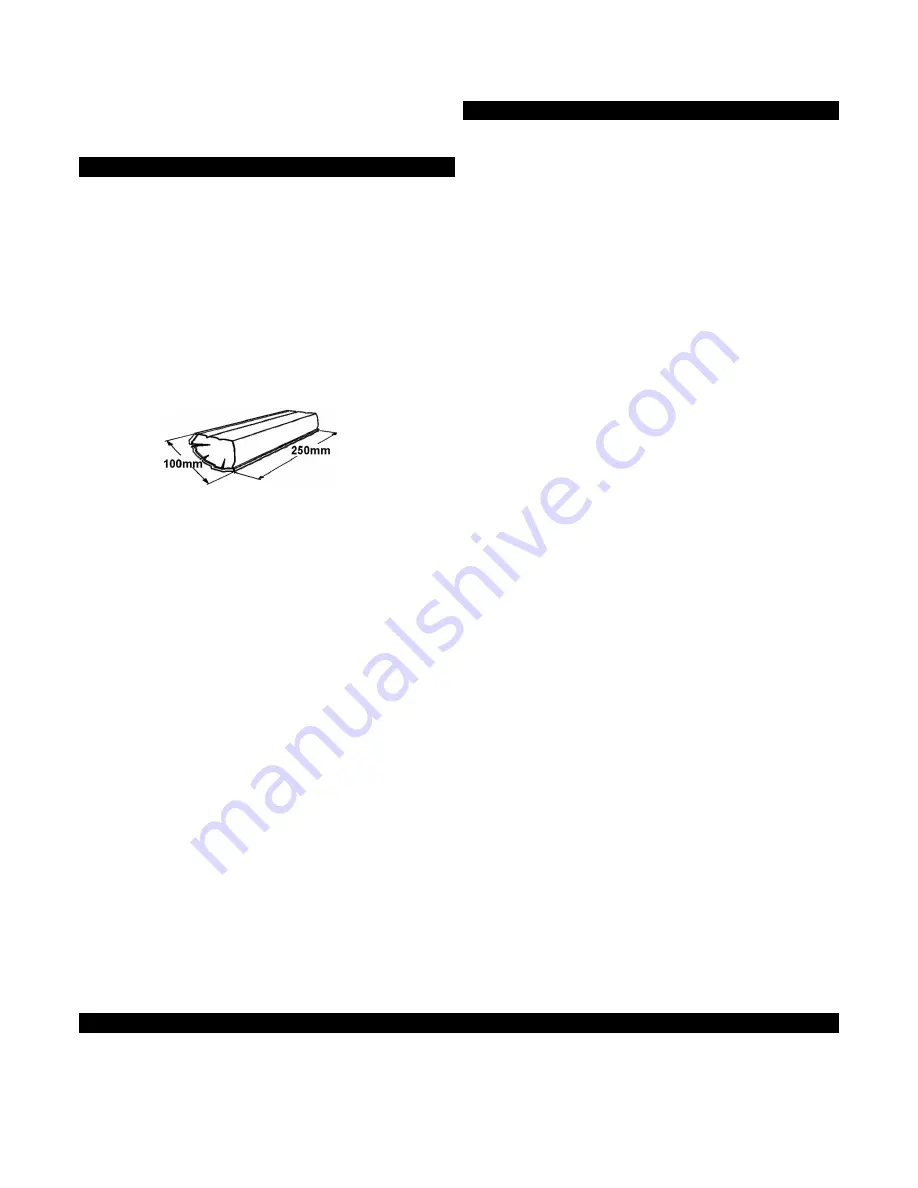

Split logs lengthways for drying

Use logs no bigger than about 100mm x 250mm

Ensure logs are

absolutely dry

(less than 15% moisture)

Fill the stove criss-cross, so air can circulate between logs.

Fill 'little and often'

Always have the airwash control (2) at least a little open.

When first lighting, or reviving a fire from embers, use only

very small, thin, dry, sticks.

Never operate with the door open.

Don't overfill the firebox – see the diagram above.

JOINERY WASTE

Dry wood offcuts will burn well, but don't expect

softwood waste to burn as cleanly or for as long as dry hardwood

logs.

PEAT:

Sod turf must be thoroughly dry. BNM peat briquettes are

approved for use in Smokeless Zones in the RoI.

LIGNITE

(not smokeless) is a natural mineral, between peat and

coal. It lights easily and burns well, but produces much ash

HOUSECOAL

or

BITUMINOUS COAL

(not smokeless) makes

lots of tarry smoke and large volumes of flammable gas which

make it difficult to control and risk explosions. Despite its low cost,

it rarely represents value for money. Don't use housecoal.

ANTHRACITE

(Smokeless) is a natural hard, shiny form of coal.

Slow to light, it can burn for very long periods with great heat.

Despite its high price-per-bag it generally works out to be one of

the cheapest of all fuels. Use the 'small nuts' size.

COKE

(Smokeless) is coal from which the smoke has been

removed. Sometimes difficult to light, it burns very cleanly.

BRIQUETTES

Are compressed blocks of fuel, generally able to

burn for long periods and remarkable for their consistency.

'Homefire' and 'Phurnacite' are smokeless types while other

brands are made from lignite, peat or housecoal.

PETROLEUM COKE

sold as 'Petcoke', 'Longbeach' and under

various proprietary names, is made from oil. Easy to light and to

control, its exceptional heat and lack of protective ash mean that it

MUST NOT be used.

HOUSEHOLD WASTES

Some plastics give off toxic fumes when

burned and remember that batteries and aerosols explode! The

stove is not an incinerator, so only ever use the recommended

fuels and NEVER use liquid fuels in any form.

PROBLEMS

Problems like those listed here are usually due to some difficulty

with the installation, chimney or fuels, so please check back

through this leaflet carefully. If necessary seek specialist advice.

SMOKE FROM THE CHIMNEY

It is quite normal for a little smoke

to be emitted from the chimney when the fire is cold, so, start the

fire using only a very little fuel. Make sure that the airwash

control is open and use only VERY dry wood or smokeless fuels.

DAMAGED LINERS

Your stove gets very, very hot inside, it is

quite usual for the replaceable liners to crack or craze. They need

only be replaced when they have almost completely disintegrated.

Help them last longer by using only

very

dry

fuel.

POOR HEAT OUTPUT:

A stove can heat a typical room of

about

12m³ volume for each kW of output, so a 5kW model can heat up

to (12 x 5) 63m³, a room of about 5m square. The actual size

depends on the insulation and air-change ratio of the room. To

attempt to heat a larger room will result in excessive fuel

consumption and damaging overheating.

LACK OF CONTROLLABILITY

This appliance is designed to

always burn vigorously enough to eliminate smoke - adjust the

heat output by how much fuel you put on, as well as by using the

controls.

DIFFICULTY BURNING FOR EXTENDED PERIODS

This stove is

not designed for extended burning but for quick heat-up and

occasional use. Longer burning can be achieved only using very

hard fuels such as anthracite.

CONDENSATION

onto cool surfaces inside the stove can be

severe if fuel is in any way damp.

Use only very dry fuel.

OVER-FIRING:

It is possible to leave the fire too long with the

controls set too high leading to 'over firing', seen as glowing metal

parts, excessive chimney temperature and risk of parts failing or

chimney fires. Always set controls to the lowest practical setting.

SMOKE COMING INTO ROOM

Fumes are poisonous- smoke

emission must NEVER be tolerated, causes might be:

NEW STOVE: There is often a smell and sometimes visible fumes

as the paint cures. This normally stops after an hour or so.

INADEQUATE SEALS: Are all flue pipes and connectors

absolutely

gas-tight? Even the tiniest crack or gap can spoil the

draught.

BLOCKED THROAT PLATE: Has soot and ash collected on the

'throat plate' above the inner back part of the firebox?

UNSUITABLE, BLOCKED OR UN-SWEPT CHIMNEY: The first

requirement for correct operation is a sound chimney. Check the

requirements earlier in this document and in any case of doubt

engage a professional sweep or chimney engineer.

POOR AIR SUPPLY: Lack of air to the fire is a common cause of

smoking and poor performance. Air supply problems may be

worse in certain wind conditions (often incorrectly ascribed to

'downdraught', which is in fact very rare), where air can be sucked

out of the room. The answer is to fit an air vent, as near to the fire

as possible, facing into the usual wind direction.

DOWNDRAUGHT: Wind can blow

down

a chimney if there is

something higher nearby such as a tree, hill or high building.

Fitting an anti-downdraught cowl to the chimney top can cure this.

Types which cannot be swept through are not recommended.

POOR CHIMNEY DRAUGHT- Chimney draught in use MUST be

at least 12Pa.

CHIMNEY FIRE:

In the rare event of deposits inside the chimney

igniting (roaring sound + dense smoke and sparks from the

chimney) immediately close the door, shut all air controls and call

the fire brigade. Prevent fires by using

very dry fuel

and having

your chimney swept regularly.

MAINTENANCE

MONTHLY- CLEAN THE THROAT PLATE and CHECK THE DOOR SEALS

The throat plate (sometimes called a baffle plate) is the

cast-iron plate inside the roof of the stove, item (9) in the diagram below. It serves to distribute flames towards the sides and top of the

fire and so increase heat output. Remove the plate when the stove is cool to brush off any deposits of soot or ash which might cause a

blocked chimney. Check that the door seals are undamaged, (replacing them if necessary) and that they fully seal against the stove

body. After a period of use the seals can become compressed - if this happens, open the door and lift it upwards to remove, screw in

3