7

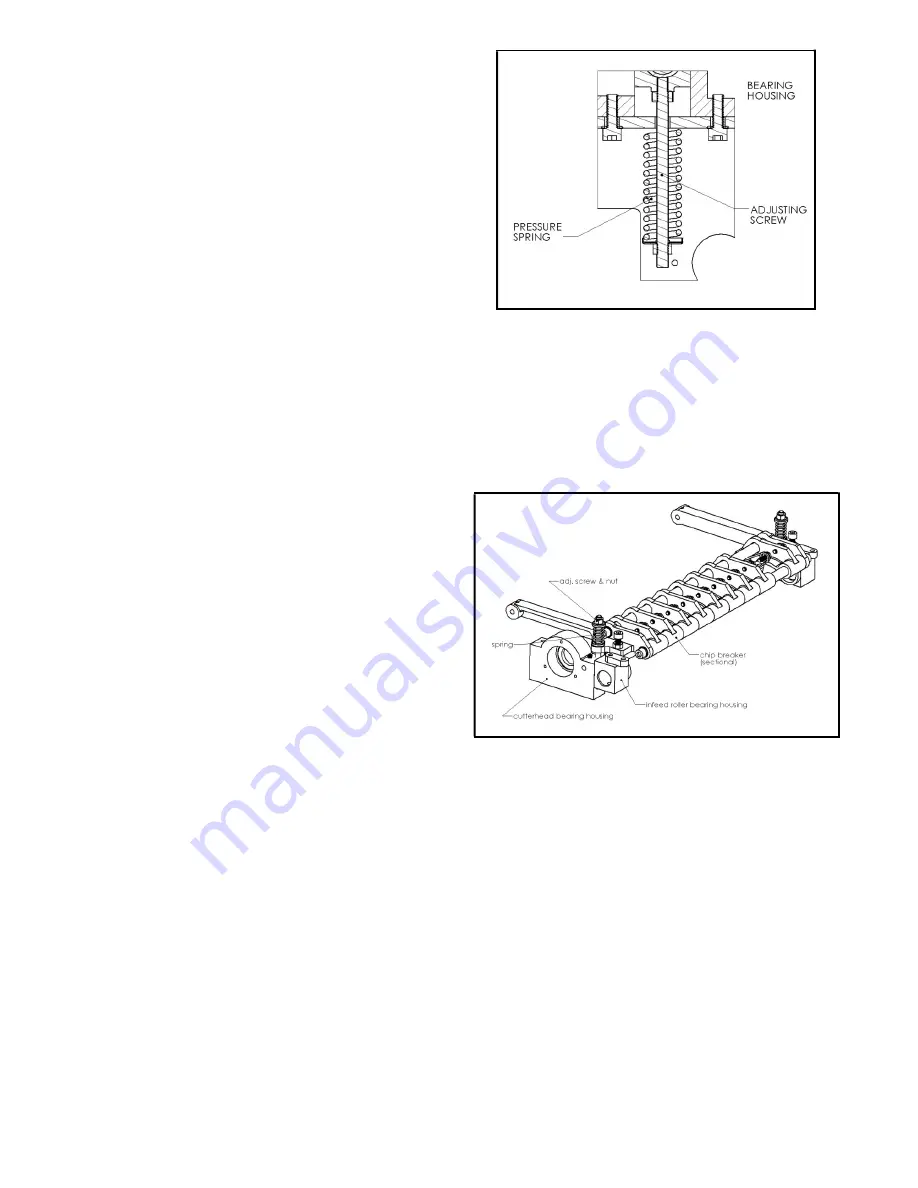

Recheck the right side and then lock the adj. screw with the nut

provided. The most accurate method of setting the infeed roll is

with the bed and feed roll gage. Find the low point of the knife arc

to the end of the gage then set the infeed roll to 0.062 for

sectionalized infeed rolls below the zero point. It is important that

the setting on both sides of this infeed roll be close to the same

height to help avoid skewing of the material as it is fed through the

machine. Infeed roll pressure is controlled by springs and is

adjusted by use of screws located under the side panels (Fig. 8)

pressure should be slightly higher on the drive side to help avoid

skewing of board as it feeds through.

Fig. 8

5-3 Chip Breaker:

The sectionalized chip breaker is constructed of 2"(50.8mm) wide spring-loaded sections mounted on a bar. Each sation has approximately

1/4"(6.4mm) independent yield. The functions of the chip breaker are to help avoid splintering out of the wood, to break chips into small

pieces, to help avoid board bounce thinner board bounce on thinner boards, to direct the flow of chip out of the machine. And to permit

multiple boards surfacing up to 1/4"(6.4mm) difference in thickness on the sectionalized type.

The chip breaker in its free position should 1/32" (0.8mm) below

the cutting arc of the knives, the same as the infeed roll, using the

same method as indicated for the infeed roll, remove the cover over

the top scction of the planer, adjust the chip brcaker free position

using a 2 x 4 gage block and shop scale of the proper thickness and

adjusting screws at each end. It is important that each end be close

to the same height to help avoid skewing of the material as it is fed

through the machine (Fig. 9)

(Caution: A chip breaker set too low may prevent stock from

feeding into the machine.)

Fig. 9

5-4 Outfeed Roll:

The outfeed roll is smooth and of one-piece construstion to help avoid marring the finished surface of the material being cut. Its function is to

continue to feed the material through the machine after it leaves the infeed roll. The correct free position setting is 1/32" (0.8mm) below the

arc of the cutterhead knives. Using the gage block or a finished 2 x 4 on edge with a 1/32" (0.8mm) shop scale on top under the cutterhead,

raise the table and rock the cutterhead to establish the low point of the knife arc. Remove the scale and position the gage or 2 x 4 under the

right side of the outfeed roll. Raise or lower its right hand bearing support with the adj. screws provided (Fig.8) to a light drag fit. Move the

gage or 2 x 4 under the left hand end and adjust in the same way. The most accurate method of setting the outfeed roll is with the bed and

feed roll gage. Zero the gage to the low point of the cutterhead arc and set each end of the outfeed roll to .031(0.787mm) below the zero on

both sides. Lock the adj. screws with the nuts provided. Out feed roll presure is controlled by springs and is adjsuted by use of screws located

under the side panels (Fig. 8). Unblanced pressure can result in skewing of the board as it feeds through.