- 9 -

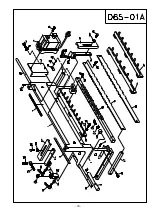

1. To replace the fixed chaser, remove the three M6

socket head cap screws and flat washers, using a

5mm hex wrench as shown in Figure 17. Remove the

fixed chaser.

2. Install the new fixed chaser and make sure it is level

with the main table.

3. Re-insert and tighten the socket head cap screws

against the flat washers.

After mounting the fixed chaser, make sure it will

correspond to your chosen pitch on the template bar.

With the

machine power off

, slide the headstock across

the length of the fixed chaser, allowing the cutter to

move in and out of the spaces. If there is any

interference between the cutter and one of the “fingers”

on the fixed chaser, then try a different fixed chaser, or

change the pitch of the template bar.

Horizontal and Vertical Fences

The workpieces will lie flush against the fences during

cutting to ensure squareness. Two buffer pads made of

polyethylene material are mounted to the fences - these

provide a “chip breaker” effect to prevent chip-out on the

left edges of the workpieces. They are designed so the

cutter can bite into them without any damage to the

cutter.

To adjust these fences, proceed as follows:

1. Place your

FRONT/BACK

workpiece on the

horizontal table and against the fence/buffer pad.

Move the headstock to the left edge of the workpiece,

then slide it to the right, allowing the tracer pin to slide

just a little into the template recesses, while observing

through the dust hood window the progress of the

cutter. This will give you an idea where the cuts will be

made and how they will be spaced across the width of

the workpiece.

2. For broad movement of the horizontal fence, loosen

both locking handles on the horizontal fence (A and B,

Figure 17) and slide the horizontal fence into position.

Tighten both locking handles (A & B, Figure 17).

3. There is also a micro adjustment on the horizontal

fence; loosen locking handle (A, Figure 17), but leave

locking handle (B) tight. Loosen the screw rotate the

knurled knob (D, Figure 17) as needed for precise

positioning of the horizontal fence.

4. When finished, locking handle (A, Figure 17).

Fingure 17