0

0

0-3

0-3

Explanation of Symbols

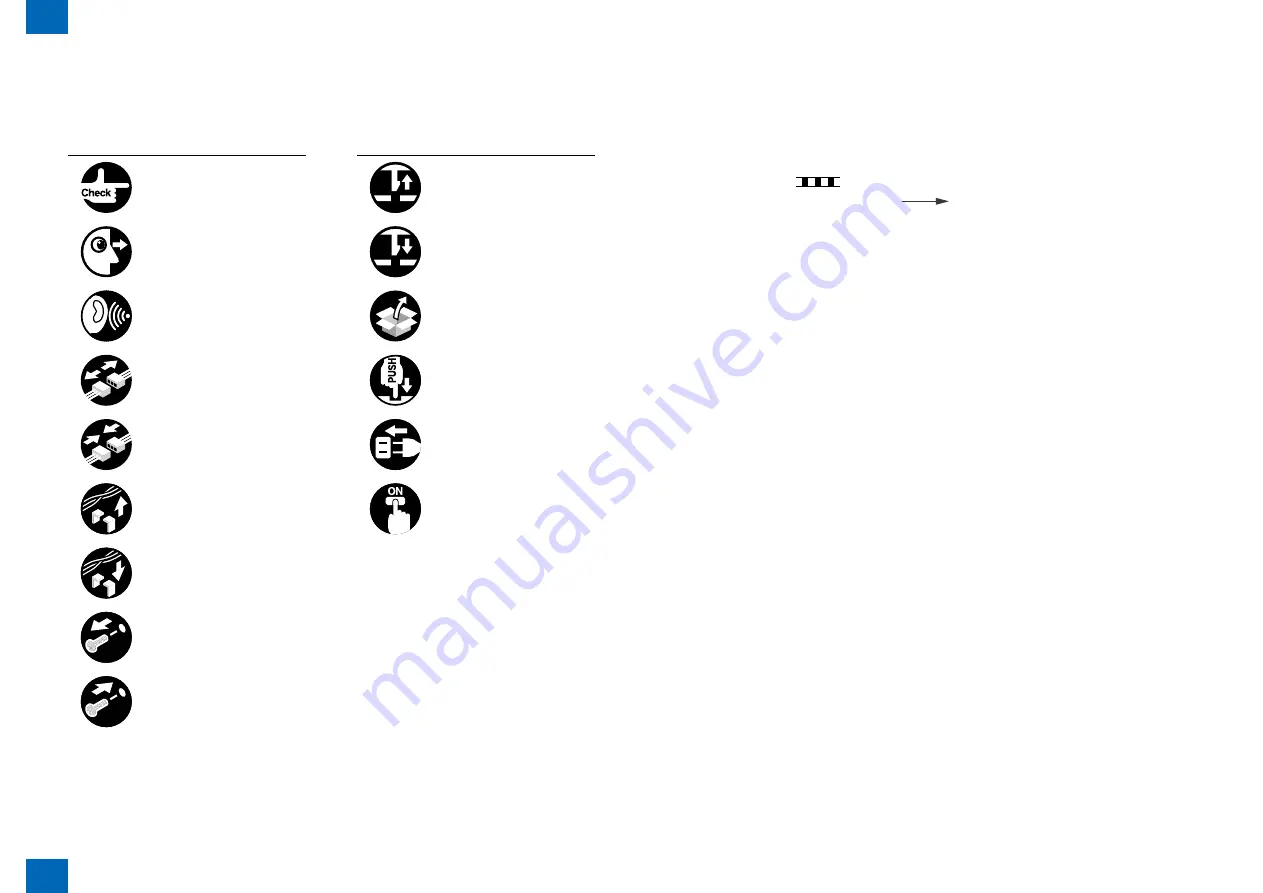

The following symbols are used throughout this Service Manual.

Symbols

Explanation

Symbols

Explanation

Check.

Remove the claw.

Check visually.

Insert the claw.

Check the noise.

Use the bundled part.

Disconnect the connector.

Push the part.

Connect the connector.

Plug the power cable.

Remove the cable/wire

from the cable guide or wire

saddle.

Turn on the power.

Set the cable/wire to the

cable guide or wire saddle.

Remove the screw.

Tighten the screw.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the

relationship between electrical and mechanical systems with reference to the timing of

operation.

In the diagrams,

represents the path of mechanical drive; where a signal name

accompanies the symbol, the arrow

indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the

front door, and closing the delivery unit door, which results in supplying the machine with

power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is

"High", while '0' is used to indicate "Low". (The voltage value, however, differs from

circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the field. Therefore, the operations of the microprocessors used in the machines

are not discussed: they are explained in terms of from sensors to the input of the DC

controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service

Manual and all relevant Service Information bulletins and be able to identify and isolate faults

in the machine.

Содержание Puncher Unit-BF1

Страница 4: ...空白ページ ...

Страница 6: ...0 0 0 6 0 6 ...

Страница 7: ...0 0 0 7 0 7 ...

Страница 8: ...Safety Precautions Notes Before it Works Serving ...

Страница 10: ...1 1 Product Outline Features Specifications Names of Parts ...

Страница 14: ...2 2 Technology Basic Configuration Controls ...

Страница 24: ...3 3 P a r t s R e p l a c e m e n t a n d C l e a n i n g Procedure Removing this Equipment List of Parts ...

Страница 33: ...4 4 Installation Checking the Contents Installation Procedure ...

Страница 47: ...5 5 Appendix General Circuit Diagram ...