COPYRIGHT © CANON ELECTRONICS INC. 2012

CANON P-208 FIRST EDITION

3-13

CHAPTER 3 DISASSEMBLY & REASSEMBLY

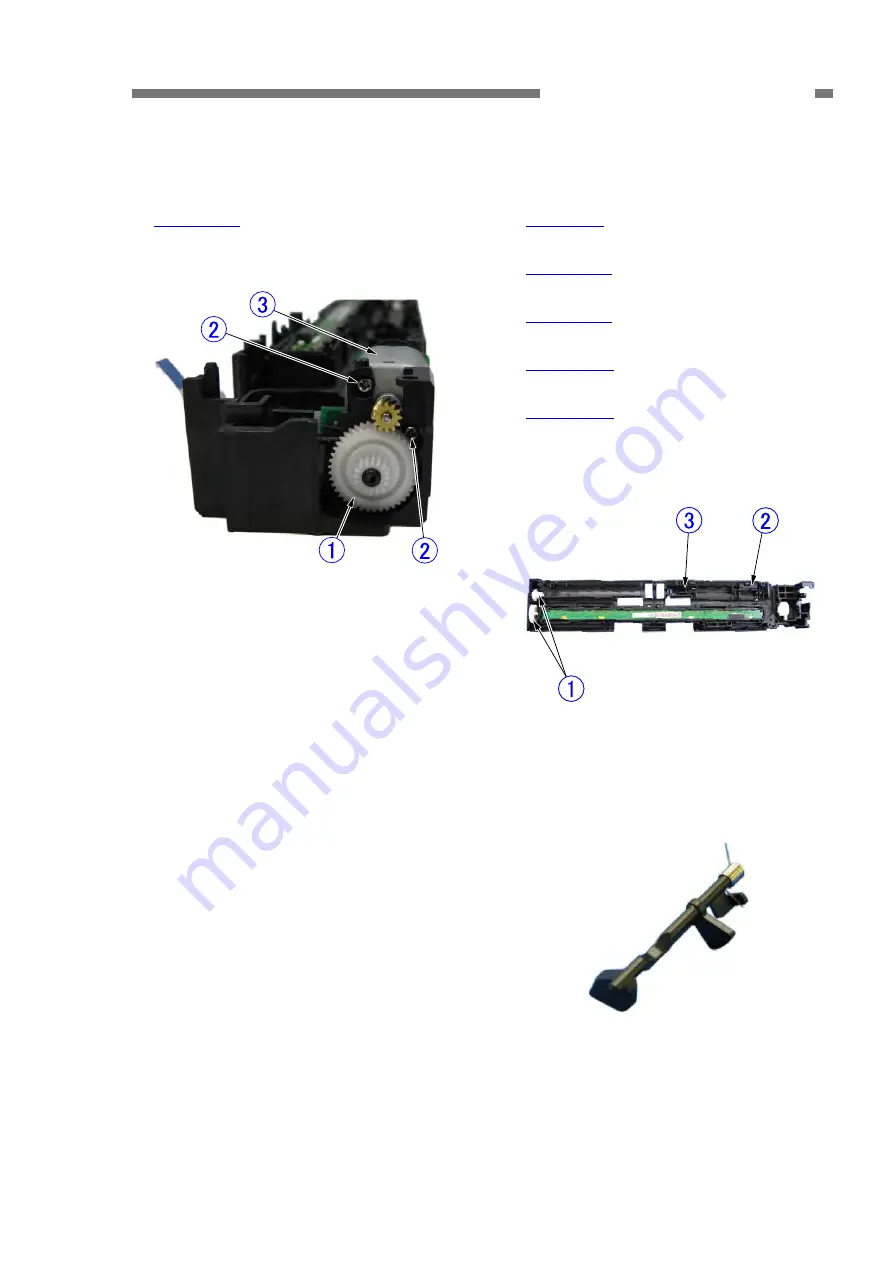

5. Motor

1) Remove the registration roller (drive).

2) Remove the gear

{

1

and 2 screws

{

2

(PH

M2x2) and remove the motor

{

3

.

Figure 3-309

Notes on assembling

Insert the gear while rotating it slightly

because it is in the form of helix.

Insert the cable into its original position

and install the motor.

6. Lower Reading Unit

1) Remove the entire upper unit.

2) Remove the eject roller (drive).

3) Remove the registration roller (drive).

4) Remove the feed roller.

5) Remove the motor.

6) Remove the 2 gears

{

1

, the open detec-

tion lever

{

2

and the document detection

lever

{

3

.

Figure 3-310

Note:

The document detection lever is as-

sembled with a spring. An assembling

drawing is shown below.

Figure 3-311

Содержание P-208

Страница 6: ......

Страница 8: ......

Страница 18: ......

Страница 20: ......

Страница 40: ......

Страница 42: ......

Страница 58: ......

Страница 64: ......

Страница 66: ......

Страница 110: ......

Страница 112: ......

Страница 117: ...COPYRIGHT CANON ELECTRONICS INC 2012 CANON P 208 FIRST EDITION A 5 APPENDIX 2 Upper Unit Figure 200...

Страница 119: ...COPYRIGHT CANON ELECTRONICS INC 2012 CANON P 208 FIRST EDITION A 7 APPENDIX 3 Base Unit Figure 300...

Страница 122: ......

Страница 124: ...1212TG...