*1: When 24 to 60 hours have elapsed since the previous Black cleaning, timer cleaning - 0 is

performed. However, this cleaning will be conducted up to 5 times from the printer installation,

and no further timer cleaning - 0 will be performed.

*2: The period of time since the previous cleaning is counted by Black and Color separately. For

this reason, the cleaning mode may differ according to Black or Color.

*3: When only the black ink tank is replaced, Black cleaning is performed. One of the color ink

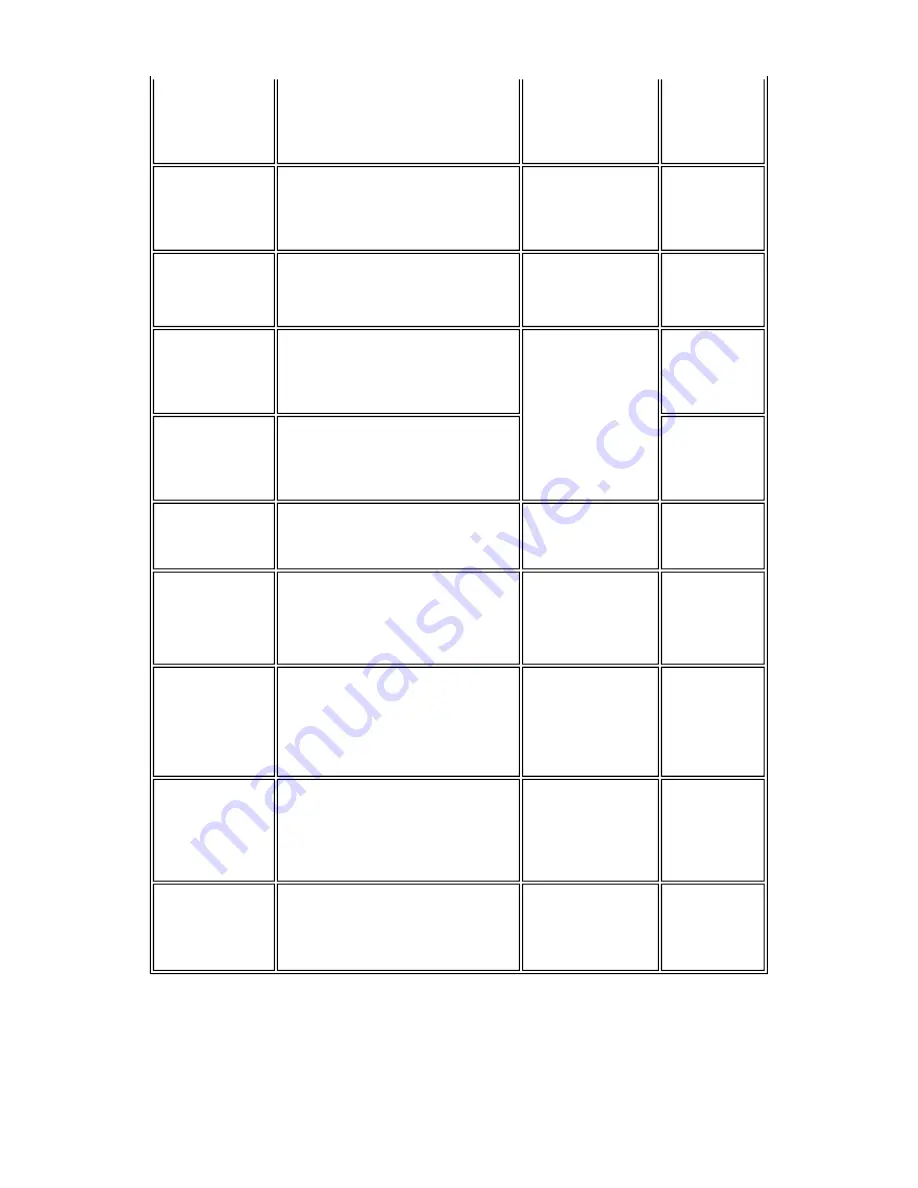

Timer cleaning - 6

(All in sequence)

If 720 to 1,080 hours have elapsed

since the previous Black/Color

cleaning till the start of the next

printing.

80

Timer cleaning - 7

(All in sequence)

If 1,080 to 2,160 hours have elapsed

since the previous Black/Color

cleaning till the start of the next

printing.

1.27 (Black)

1.06 (Color)

85

Timer cleaning - 8

(All in sequence)

If 2,160 to 4,320 hours have elapsed

since the previous Black/Color

cleaning till the start of the next

printing.

1.95 (Black)

1.06 (Color)

90

Timer cleaning - 9

(All in sequence)

If 4,320 to 8,640 hours have elapsed

since the previous Black/Color

cleaning till the start of the next

printing.

1.95 (Black)

1.06 (Color)

90

Timer cleaning -

10

(All in sequence)

If 8,640 or longer hours have elapsed

since the previous Black/Color

cleaning till the start of the next

printing.

90

At print head

replacement

(All in sequence)

When the print head is removed and

installed.

0.57 (Black)

2.25 (Color)

100

At ink tank

replacement

*3

(Black/Color/All in

sequence)

When an ink tank is replaced (without

the print head removal or re-

installation)

0.38 (Black)

1.06 (Color)

80 (All in

sequence)

40 (Black)

65 (Color)

Manual cleaning

(Black/Color/All at

the same time)

- Via the operation panel (All at the

same time only)

- Via the printer driver (Selectable

from Black, Color, or All at the

same time)

0.20 (Black)

0.65 (Color)

45 (All at the

same time)

35 (Black)

40 (Color)

Deep cleaning

(Black/Color/All at

the same time)

Via the printer driver (Selectable from

Black, Color, or All at the same time)

1.95 (Black)

1.06 (Color)

90 (All at the

same time)

45 (Black)

65 (Color)

If the print head

has not been

capped before

power-on

(All in sequence)

0.38 (Black)

1.06 (Color)

80 (All in

sequence)

2-3

Содержание iP5200R - PIXMA Color Inkjet Printer

Страница 5: ...Part 1 MAINTENANCE ...

Страница 25: ...To the top Part 1 3 REPAIR 3 2 1 20 ...

Страница 27: ...2 CL base CL gear 1 22 ...

Страница 28: ...3 PR shaft LF roller bushing To the top Part 1 3 REPAIR 3 3 1 to 2 1 23 ...

Страница 40: ...Part 2 TECHNICAL REFERENCE ...

Страница 45: ...3 PRINT MODE 3 1 Resolution 1 Normal color printing 2 Grayscale printing 3 Borderless printing 2 5 ...

Страница 46: ... 4 Duplex printing 5 Camera Direct printing To the top Part 2 3 PRINT MODE 2 6 ...

Страница 53: ...Part 3 APPENDIX ...