imageFORMULA DR-G1130/DR-G1100 Series Service Guide

imageFORMULA DR-G1130/DR-G1100 Series Service Guide

April 2013

Rev. 1

Page 9

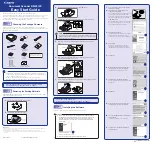

E. Periodic Maintenance

Some parts of the machine must be checked and/or replaced on a periodic basis

by the service technician and/or the end-user to ensure a specific level of machine

performance.

These parts are likely to affect the performance once they fail even in the absence

of external change or damage. Whenever possible, the service technician should

plan their replacement and/or cleaning as scheduled in the below table.

Service Technician Periodic Maintenance (Table 6)

Location/Parts

Every

4,500,000

sheets

Every

6,000,000

sheets

Remarks

Reading Unit

Replace /

Adjust

Replace /

Adjust

Needs adjustments when replacing.

Rollers for document

Replace

Bearings also need replacement at the

same time as when the rollers are

replaced.

Inside

Clean

Clean

Clean these areas at the same times

as the above Periodic Maintenance are

performed.

Feed Path

Clean

Clean

End-User Periodic Maintenance (Table 7)

Location/Parts

As

Necessary

Other

Remarks

Pickup Roller

Clean

Replace

Wipe with a soft cloth that is slightly

moistened with after, then wipe dry.

Approximate life for rollers: 600,000

sheets.

Approximate life for separation front

cover: 6,000,000 sheets

Feed Roller

Retard Roller

Separation Front Cover

Other Rollers

Wipe with a soft cloth that is slightly

moistened with after, then wipe dry.

Reading Glass

Wipe with a dry soft cloth.

Feed Path

Using a blower, remove dust and paper

powder from the pickup area and the

feed path including the sensors.