Chapter 9

9-2

9.2 Various Control Mechanisms

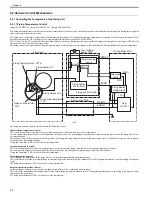

9.2.1 Controlling the Temperature of the Fixing Unit

9.2.1.1 Fixing Temperature Control

0019-5047

imageCLASS MF9170c / imageCLASS MF9150c / imageCLASS MF8450c

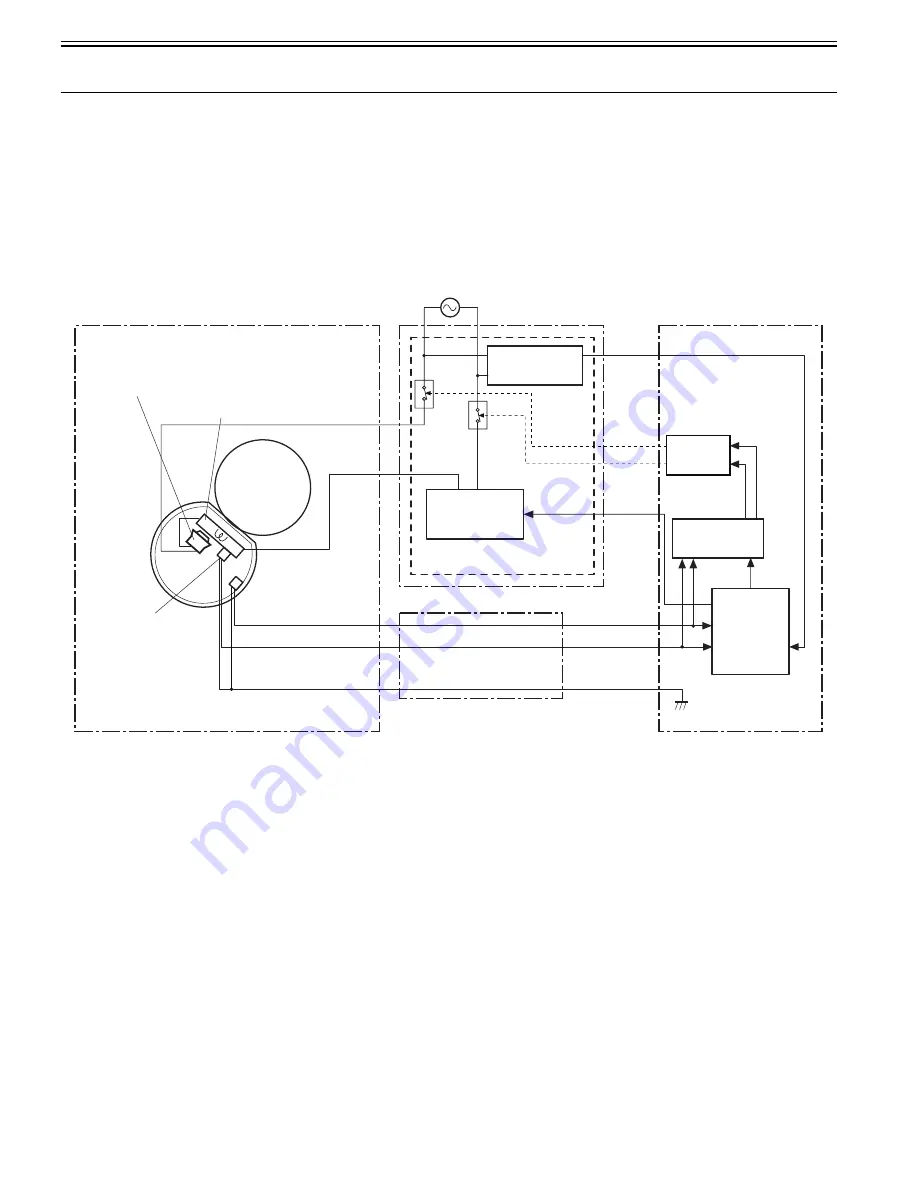

The fixing temperature control is to detect the surface temperature of the fixing sleeve and the fixing heater, and to maintain the fixing heater temperature at targeted

value according to the detected results.

The fixing sleeve temperature is monitored by the fixing main thermistor (TH1) and the fixing heater temperature is monitored by the fixing sub thermistor (TH2).

Results are output to the DC controller as the fixing temperature detection signal (MAINTH, SUBTH).

CPU (IC1001) on the DC controller PCB monitors the voltage of the fixing temperature detection signals and outputs the fixing heater drive signal (FSRD) to the

fixing control circuit based on the voltage value.

The fixing control circuit controls the fixing temperature based on the fixing heater drive signal so that the heater can be maintained at the targeted temperature.

F-9-2

The fixing temperature controls are divided into the following 4 types.

Initial rotation temperature control

CPU firstly turns ON the fixing heater for a specified period at power-ON and then, drives the fixing motor.

In a low temperature status such as at initial operation, the fixing sleeve may get damaged when the paper is fed because the grease inside the fixing sleeve is not

yet smooth enough.

This control is to melt the grease inside the fixing sleeve by heating the fixing heater before the fixing motor drives and to lubricate the sleeve in order to prevent

the fixing sleeve from being damaged.

Fixing sub thermistor (TH2) is used to detect the temperature.

Start-up temperature control

CPU heats the fixing heater to the start-up temperature in order to warm the fixing assembly up to the required temperature for fixing.

The start-up temperature varies depending on the elapsed time since previous print completion, paper types, and environments.

Fixing sub thermistor (TH2) is used to detect the temperature.

Print temperature control

CPU maintains the temperature of the fixing sleeve at its targeted temperature during print operation.

CPU gradually switches the target temperature in one printing process depending on the number of print. The targeted temperature varies depending on the paper

types.

The fixing main thermistor (TH1) is used to detect the temperature.

Between-sheets temperature control

At the continuous printing in low-speed mode, the pressure roller may be overheating between sheets.

CPU reduces the temperature of hexing heater below the normal fixing temperature between sheets. The targeted temperature varies according to the between-sheets

intervals and the paper types.

The fixing main thermistor (TH1) is used to detect the temperature.

RL3902

RL3901

Fixing sleeve unit

Fixing main thermistor

: TH1

Fixing heater

safety circuit

Low-voltage

power PCB

Fixing relay PCB

CPU

(IC1001)

DC controller PCB

Fixing sub thermistor

: TH2

FSRD

Fixing unit

MAINTH

SUBTH

FLD+

RLD-

ZEROX

Fixing control circuit

Fixing heater

drive circuit

Relay drive

circuit

Zero crossing

circuit

RLD+

Fixing thermal switch: TP1A

Fixing heater: H1

Содержание imageCLASS MF8450c

Страница 16: ...Chapter 1 Introduction ...

Страница 55: ...Chapter 2 Basic Operation ...

Страница 61: ...Chapter 3 Main Controller ...

Страница 75: ...Chapter 4 Original Exposure System ...

Страница 88: ...Chapter 5 Original Feeding System ...

Страница 105: ...Chapter 6 Laser Exposure ...

Страница 113: ...Chapter 7 Image Formation ...

Страница 150: ...Chapter 8 Pickup and Feed System ...

Страница 184: ...Chapter 9 Fixing System ...

Страница 200: ...Chapter 10 External and Controls ...

Страница 230: ...Chapter 11 Maintenance and Inspection ...

Страница 233: ...Chapter 12 Measurement and Adjustments ...

Страница 237: ...Chapter 13 Correcting Faulty Images ...

Страница 251: ...Chapter 13 13 13 13 3 5 PCBs 13 3 5 1 PCBs 0019 5065 imageCLASS MF9170c imageCLASS MF9150c imageCLASS MF8450c ...

Страница 256: ...Chapter 13 13 18 F 13 19 21 22 28 29 30 31 24 14 15 16 23 26 25 32 27 20 19 18 17 2 13 6 10 33 1 8 4 3 12 11 5 7 9 ...

Страница 260: ...Chapter 14 Error Code ...

Страница 272: ...Chapter 15 Special Management Mode ...

Страница 280: ...Chapter 16 Service Mode ...

Страница 322: ...Chapter 17 Upgrading ...

Страница 327: ...Chapter 17 17 4 3 Click Next F 17 4 4 Select a USB connected device and click Next F 17 5 ...

Страница 328: ...Chapter 17 17 5 5 Click Start F 17 6 6 Click Yes F 17 7 Download will be started F 17 8 ...

Страница 330: ...Chapter 18 Service Tools ...

Страница 334: ...Appendix ...

Страница 349: ......