5

3. ERROR DIAPLAY

Errors are displayed by the LEDs, and ink low warnings are displayed by the status monitor.

3-1. Operator Call Error (Orange LED blinking)

LED Display

Content

Corrective Action

Blinking 2 times

Paper out

Set paper, and press the RESUME

button to feed the paper.

Blinking 3 times

Paper jam

Remove the jammed paper, and press

the RESUME button.

Blinking 4 times

Ink tank not installed

Re-install the ink tank, and close the

access cover.

Blinking 5 times Print head not installed or failure has

occurred in the print head.

(Not-supported print head (see page 5) is

installed or print head EEPROM data is

abnormal.)

Re-install the print head, and close the

access cover. Or confirm the print

head is “QY6-0044-000” and perform

re-installation. If not recovered with the

cartridge installed, power the printer off

and on.

Blinking 8 times Waste ink full or platen waste ink full warning

(Approx. 95% of acceptable amount)

Recoverable by pressing the RESUME

button.

3-2. Service Call Error (Orange and green LEDs blink alternately)

LED Display

Content

Corrective Action

Blinking 2 times

Carriage error

Replace the printer as it has failed.

Blinking 6 times

Internal temperature abnormal error

Replace the printer as it has failed.

Blinking 7 times

Waste ink full or platen waste ink full error

Replace the printer as it has failed.

Blinking 8 times

Abnormal temperature rise

Replace the printer as it has failed.

Blinking 9 times

EEPROM error

Replace the printer as it has failed.

Blinking 10 times No cartridge detected excepting print head

replacement (during printing)

Replace the printer as it has failed.

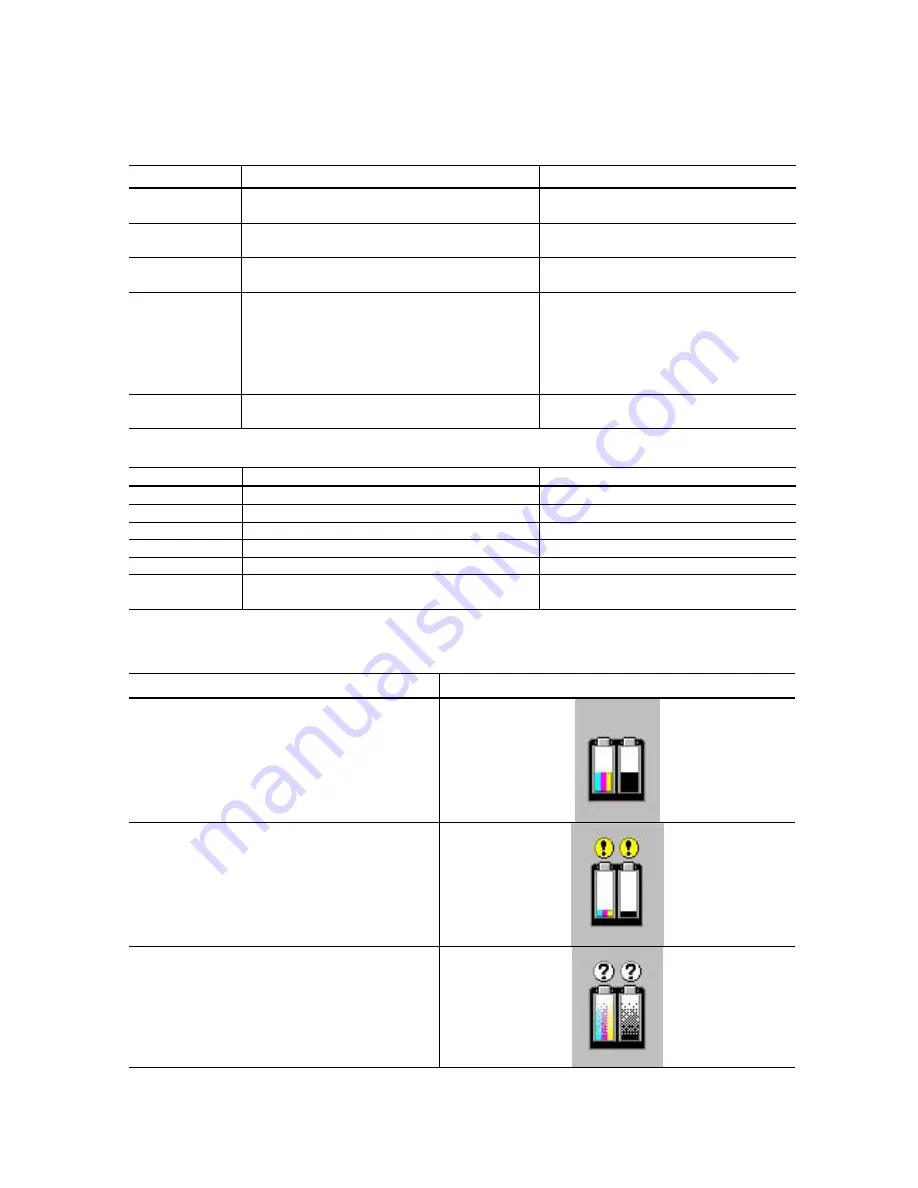

3-3. Ink Low Warning (Ink low warnings are displayed by the status monitor only when the remaining

ink level detection is on, and no status monitor display when off.)

Content

Display by status monitor

Ink low warning 1 (approx. half level)

Ink low warning 2 (low remaining ink)

Ink low warning 3 (ink level unknown)