23

�

�

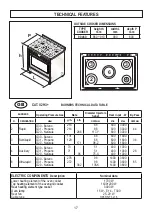

CONVERSIONS

REPLACING THE INJECTORS

Our burners can be adapted to different types of

gas by simply installing the injectors suitable for the

gas you want to use. To help the installer, the table

(see paragraph «TECHNICAL FEATURES

») gives

the burner nominal heat input, injector diameter and

operating pressure of the different gas types.

Comply with the following instructions:

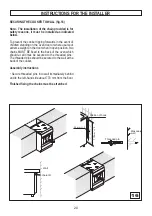

Injector replacement - Hob burners.

To change the injectors on the hob, remove

the burner cup and head and with a 7 mm

Ø socket spanner replace them (fig. 20).

After having replaced the injectors, it will be

necessary to proceed with burner adjustment

as explained in the previous paragraphs. The

technician must replace any seals after the

adjustments have been made.

20

ADJUSTMENTS

• All seal must be replaced by the technician

following any adjustment or regulation.

• The adjustment of the reduce rate (simmer)

must be undertaken only with burners

functioning on natural gas while in the case of

burners functioning on L.P.G, the screw must

be locked down fully (in clockwise direction).

• “Primary air adjustment” on hob gas burners

is unnecessary.

TAPS

All gas taps are male cone type with only one way of

passage. Adjustment of the

“Reduced rate”

position

as follows:

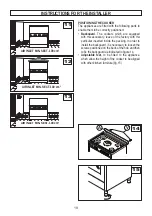

• Turn the burner on and place the knob on the

“Reduced rate” position (small flame).

• Remove the knob of the tap which is attached by

simply applying pressure to the rod.

• Insert a small screwdriver (C) into screw (V) side

of the stem (fig. 19) and turn to the right or left

the throttling cone until the flame of the burner is

conveniently regulated to the Low position.

• Check that the flame does not go out when the knob

is sharply switched from the “Full on” to “Reduced

rate” positions.

•

ATTENTION!!

This operation can be carried out

also with the front panel fitted, but if the technician

finds some difficulties to reach the adjustment

screw, remove the front panel unscrewing the fixing

screws (Vf) (fig. 24), which are positioned in the

inferior part of the same.

INSTRUCTIONS FOR THE INSTALLER

19

CHANGING THE FLEXIBLE GAS HOSE

In order to guarantee that the gas hose is always in

excellent condition we strongly recommend changing

it on the date you will find printed on it.

�

�

21

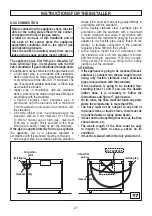

REPLACING THE ELECTRICAL COMPONENTS

• The rear protection will have to be removed in order

to change the electrical heating elements, spit

motor, terminal board and power cable.

•

If you have to change the power cable (see the

cross section on table paragraph «TECHNICAL

FEATURES

»)

, always keep the earth wire longer

than the phase wires and, in addition, follow

all the instructions given in the «ELECTRICAL

CONNECTION» paragraph.

• To change the oven lamp see the instructions on

the REPLACING THE OVEN LAMP paragraph

.

•

To change the lamp holder

, remove the side

panels and then use a screwdriver to push the two

locking tabs (fig. 21) and remove the lamp holder

from the inside of the oven.