add wood while operating. Adding wood while

operating may splash hot water and cause

serious injury.

Use of accessories not intended for smoker is

not recommended and may lead to injury or

property damage.

An LP cylinder not connected for use should

not be stored in the vicinity of smoker or any

other appliance. Do not store spare LP cylinders

within 10 feet of smoker. LP cylinders must be

stored outdoors, out of reach of children.

Do not store a spare LP-gas cylinder under

or near this appliance. Never fill the cylinder

beyond 80 percent full. Failure to follow these

instructions exactly could result in a fire

causing death or serious injury.

The smoker should be shut off and all supply

valves (on piping or on fuel cylinders) should be

closed in the event that the odor of unburned

gas is detected. Do not attempt to use the unit

until any gas leaks are fixed.

Do not use the smoker if the burner fails

to light or fails to remain lit. Under such

conditions, gas should be shut off and fuel

cylinders should be disconnected. Do not

operate under high wind conditions.

LP tanks are intended for operation in the

upright position only.

Care should be taken to protect the fuel supply

hose from damage from either foot or vehicle

traffic.

If the appliance is not in use, the gas must

be turned off at the supply cylinder and the

cylinder should be disconnected from the

appliance.

Storage of the appliance indoors is only

permissible if the cylinder is disconnected and

removed from the appliance.

All installations are to conform to local codes.

In the absence of local codes, installation

should conform to the National Fuel Gas Code,

ANSI Z223.1/NFPA 54

Smoker should be installed with the hose

regulator assembly extended at full length of

hose directly away from the burner. Keep fuel

supply hose away from any heated surfaces.

When so configured, placement results in

maximum tank to smoker distance. When

smoker is operated, the hose/regulator and

gas tank should be on a line perpendicular to

wind direction. Placing tank closer than 24” to

the smoker can overheat the tank and cause

release of propane through relief openings and

can result in tank fire or explosion.

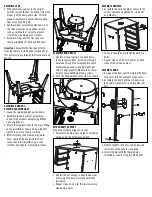

Connecting the LP Tank

1. The knob on the LP tank must be closed. See

that the knob is turned clockwise to a full stop.

2. Check that the control knob on the smoker is

turned off.

3. Remove the protective cap from the LP tank

valve and coupling nut, if present.

4. Hold the regulator in one hand and insert the

nipple into the valve outlet. Be sure the nipple

is centered in the valve outlet. The coupler

connects to the large outside threads on the

valve outlet.

5. Hand tighten the coupler clockwise until it

comes to a full stop. Firmly tighten by hand

only.

6. Place the tank to the side or rear of the

smoker. Make sure the hose does not touch any

part of the burner drum housing.

CAUTION:

In the connection process, the HVR

side of the connection will seal on the back

check in the valve,

resulting in a

slight resistance.

The connection

requires about

one-half to

three-quarters

additional turn

to complete

connection.

Any fuel supply cylinder used must be

constructed and marked in accordance with

specifications for propane cylinders of the U.S.

Department of Transportation (DOT)

CFR 49 or CAN/CSA B339. The appliance is

to be used only with the 20 pound, vertical

standing vapor withdrawal type tank.

This smoker is designed to operate on LP

(Liquefied Propane) gas only.

The 20 lb LP cylinder used with this smoker

must conform to the following requirements:

•Type 1 Connections

•Diameter - 12” (30.5cm)

•Height - 18” (45.7cm)

•Maximum capacity of 20 pounds

•The gas cylinder used must include a collar to

protect the cylinder valve.

The cylinder supply system must be arranged

for vapor withdrawal. Follow the instructions

stated on gas cylinder tanks when filling or

transporting tanks. Failure to do so could result

in problems relating to overfilling, excessive

venting release of gas and to regulator

freezing.

Never fill the cylinder more than

80 percent full.

Do not allow dirt or foreign material to get into

or onto tank connection when it is not attached

to the fuel supply system. Use the protective

cap provided.

Place dust cap on cylinder valve outlet

whenever the cylinder is not in use. Only install

the type of dust cap on the cylinder valve outlet

that is provided with the cylinder valve. Other

tpes of caps or plugs may result in leakage of

propane.

Cylinders must be filled before initial use.

All handling, transport, filling and storage

of LP gas cylinders must be in accordance

with NFPA 58 Storage and Handling of Liquid

Petroleum Gasses, or CAN/CSA b149.2 Propane

Installation Code. Cylinders must be suitably

tied down during transport. Do not place any

other items on top of cylinders at any time.

Cylinders are not to be exposed to excessive

temperatures or high heat. Refer to the data

plate for model identification. Units are

factory equipped for use on only one type of

fuel. These units cannot be, and should not

be used on other types of fuels. Doing so can

cause severe damage to the unit and the

installation area and the added risk of serious

injury. Any attempt to operate this product on

fuels for which it is not designed voids the

manufacturer’s warranty.

This unit is not to be utilized with a non-self-

contained LP-gas supply system.

The pressure regulator and hose assembly

supplied by the manufacturer with the

appliance must be used. Replacement pressure

regulators and hose assemblies must be those

specified by the appliance manufacturer. See

rating sticker on side of appliance for regulator

model number.