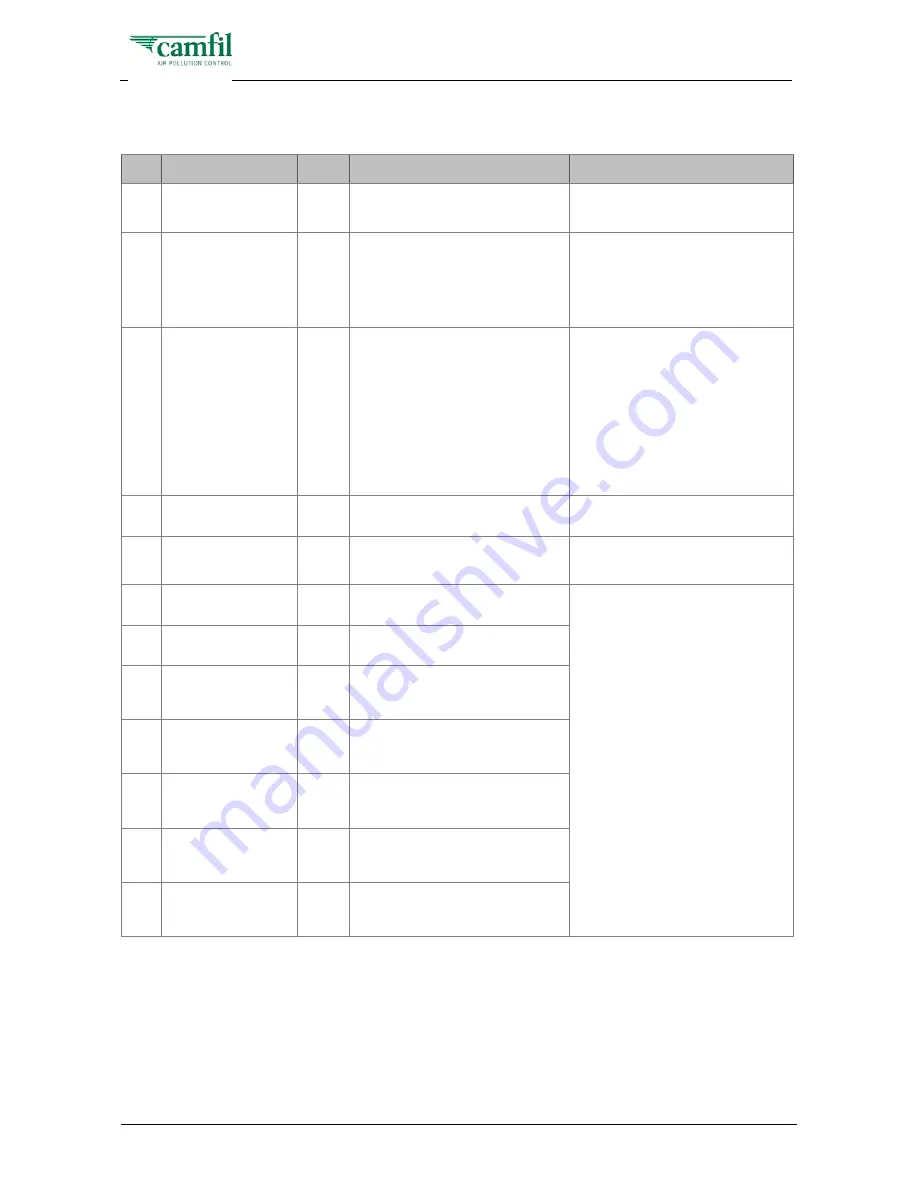

Intervals:

D

=

daily,

W

=

weekly,

M

=

monthly,

3M

=

every 3

months,

6M

=

every 6

months,

Y

=

yearly

Item

Maintenance

point

Interval

Type

of

check/maintenance

task

Comments

3

Water

tank

Drain

or

pump

out

the

contents

of

the

water

tank.

3.1

Sealing

band

W

CLEANING:

7.

Clean

the

sealing

faces

and

then

degrease

them

using

acid

‐

free

grease.

IF

NECESSARY:

8.

Replace

the

rubber

band

if

it

is

defective.

9.

If

necessary,

adjust

the

clamp

fastener.

3.2

Water

tank

D/W

CLEANING:

10.

Drain

or

pump

out

the

sludge/dirty

water.

11.

Shovel

out

any

remaining

sludge

and

clean

the

tank

with

a

high

‐

pressure

cleaner.

12.

Fill

with

clean

water.

IF

NECESSARY:

13.

Replace

the

rubber

band

if

it

is

defective.

14.

Retouch

the

paintwork.

Water

quality

Regularly

replace

the

scrubbing

wa

‐

ter.

Please

observe

the

instructions

in

our

brochure

on

water

as

an

oper

‐

ating

resource.

3.3

Drain

ball

valve

M

FUNCTIONAL

INSPECTION:

15.

Check

the

mobility

of

the

ball.

IF

NECESSARY:

1.

Replace

the

defective

ball

valve.

4

Level

regulation

equipment

4.1

Control

box

W

CLEANING:

2.

Clean

the

control

box.

Once

cleaning

has

been

completed

and

the

scrubber

has

been

filled

with

water

again,

the

level

regulator

setting

must

be

checked.

The

regu

‐

lator

must

be

adjusted

if

necessary.

4.2

Float

W

CLEANING:

3.

Clean

the

float.

4.3

Floater

rod

(mech.

LR)

W

FUNCTIONAL

INSPECTION:

4.

Check

the

mobility

of

the

float

‐

er

rod.

4.4

Magnetic

switch

W

FUNCTIONAL

INSPECTION:

5.

Check

the

switch

function

of

the

magnetic

switch.

4.5

Solenoid

valve

W

FUNCTIONAL

INSPECTION:

6.

Check

the

switch

function

of

the

solenoid

valve.

4.6

Valve

block

W

FUNCTIONAL

INSPECTION:

7.

Check

the

mobility

of

the

valves.

4.7

Surface

cleaner

(optional)

W

VISUAL

INSPECTION:

8.

Check

the

position

of

the

sliding

plate.