14/36

5.

ASSEMBLY AND INSTALLATION

5.1.

Packing list

Description

Amount

Reference

Equipment

1

See chapter 10.2

Operating manual

1

168TA2692

Spare parts list

1

See chapter 10.4

CE certificate

1

See chapter 10.1

5.2.

Safety instructions for assembly and installation of the product

• Wear safety gloves and safety shoes when assembling the equipment.

• The assembly and installation must be carried out by an expert.

• Make sure that the goods and packaging are in good condition.

• Before commissioning, carry out a risk analysis of the assembly of the CAM attachment on

the forklift.

• Before using the equipment , carefully read the instructions in the manual of your lifting

device.

5.3.

Assembly of the product

• Before installing the equipment, a thorough visual check must be carried out to make sure

that no damage occurred during the transportation and handling stage.

• If one or more components are damaged, it is necessary to notify CAM attachments and

agree on the measures to be taken.

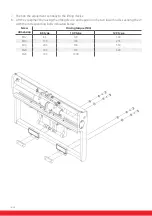

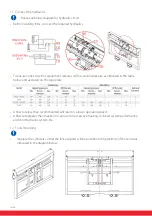

PL & PL-T

1. Remove the packing materials carefully.

2. Place the equipment on a flat surface.

3. Remove the lower hooks on both sides as indicated in the diagrams below.