3

Following each use, clean and dry tank and lid in accordance with maintenance

nstru

cti

ons.

Ensure ports to safety valve, gauge and outlet are free of hardened paint or

other materials which could prevent free movement of air.

5.

Tampering with the safety valve could allow tank pressure to rise to dangerous levels. Never

a

tt

empt to adjust safety valve to change its pressure se

tti

ng, or defeat its func

ti

on in any way.

Operate the valve before each use to assure that it func

ti

ons properly.

6.

Removal of the lid while the tank is under pressure could result in the lid being propelled

violently from the tank. Before releasing clamp force to remove the lid, shut o

ff

the supply of

tank inlet air and turn the regulator knob counter-clockwise to relieve air pressure. Check by

pulling the safety valve ring.

7.

Use of reac

ti

ve chemicals could a

tt

ack the lid gasket and safety valve seal, allowing tank

pressure to rise to dangerous levels.

If this reac

ti

on occurs within an enclosed structure such as this tank, it may cause explosion. Do not use

reac

ti

ve chemicals in your tank such as acids, caus

ti

c solu

ti

ons, or halogenated hydrocarbon

solvents.

8.

Over

ti

ghtening clamps, causing them to weaken and fail could result in the lid being

propelled violently from the tank. If the lid gasket leaks, relieve the tank pressure and clean

or replace the gasket.

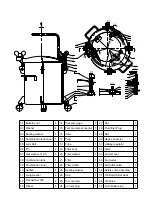

Assembly

1.

Attach the s

wivel

wheels (4) to the base legs on the tank.

2.

Attach the air hose to the inlet fitting located on the tank regulator (right or left side optional).

3

.

Connect material hose to t

he flu

id outlet adapter located on the tank lid.

Using an air pressure regulator on paint tank

The pressure regulator on the paint tank regulates the amount of pressure applied to the

paint in the paint tank. This controls the pressure of the paint being delivered to the spray gun .

Important: Before turning on air pressure, completely loosen the regulator T-handle adjus

ti

ng

screw to shut o

ff

the air pressure. Turn on the air, then, adjust the regulator to the required

pressure

.

Содержание 365C

Страница 7: ......