11

Customer Support: 1-866-409-4581

AIR COMPRESSOR

Test Run

Before using the air compressor for the first time, complete a test

run as follows:

1.

Turn the power switch to the OFF position. Plug the power

supply cord into a power supply socket. Start the air

compressor by turning the power switch to the ON position.

The air tank pressure gauge reading will slowly rise as

pressure increases inside the air tank. When the gauge

reading reaches 135 PSI (plus or minus 5 PSI), the pressure

switch will automatically turn the power off. This indicates the

compressor is working normally.

2.

Daily Operation

Starting the compressor:

1.

Turn the power switch to the OFF position.

2.

Attach the air hose to the 1/4” Industrial Male Quick Connector

3.

Close the drain valve.

4. Have air filter attached

5.

Plug the power supply cord into a power supply socket.

6.

Turn the power switch to the ON position.

7.

Let the motor run and tank fill until motor turns off.

8.

To regulate the air flow.

While the air compressor is running, turn “On” your tool and

turn the regulator knob to the right PSI position for the tool..

9.

Operate air tool normally.

10.

Do Not run continuously (non-stop) for more than 1/2-1 hour.

Shutting down the compressor:

1.

Turn the power switch to the OFF position.

2.

Unplug the power supply cord.

3.

Remove the pressure and water in the air tank through drain

valve.

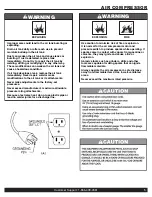

Air compressor surfaces become hot during

operation.

DO NOT touch hot surfaces, because they can cause

severe burns.

Do not touch the air compressor’s cylinder head.

During operation, the cooling fins of the cylinder

head and delivery pipe become hot.

Allow the air compressor to cool before touching it.

DO NOT place a storage cover on the unit during

operation. Only place a cover on the air compressor

after it has thoroughly cooled down.

FIRE

HOT SURFACE

WARNING

Flying objects can cause injury to the eyes, head and

other parts of the body.

Air-powered equipment and power tools are capable

of propelling items (metal chips, fasteners and

particulates) at high speed into the air and could

result in injury.

Always wear approved head and eye protection.

Never point the air stream at any part of your body,

or at another person or animal.

When operating the air compressor, make sure all

other people and animals maintain a safe distance.

Do not move the air compressor when the air tank is

under pressure.

Never use the air hoses to pull or move the air

compressor.

Keep the air compressor on a flat surface.

WARNING

FLYING OBJECTS

Note:

If the Air Compressor is not working properly, the

pressure gauge will indicate that there is a decrease in

pressure in the air tank. If there is an air leak from the

compressor the pressure in the air tank decreases, the

pressure switch resets and the motor automatically turns

back on.

If you detect an air leakage, turn the power switch to the

Off position, release the air from the tank by pulling on

the safety valve. Unplug the power supply cord and contact

Customer Support for Assistance.

Turn the power switch to the Off position, unplug the power

supply cord and release the air in the air tank by opening the

drain valve at the bottom of the tank. At this point proceed to

the next step (daily operations).