8

9

3

Operation

3.1

Standard Operation

Check all external connections.

Load the material. Ensure that the locking system is locked

"Operator's Manual" of the printer.

Switch on the printer.

Press the

feed

key on the printer.

A synchronization feed is released. The processed labels have to be removed manually. After a few seconds the

printer carries out a short backfeed to position the front edge of the next label at the printing line.

i

Note!

The synchronization also has to be carried out when the print job has been interrupted with the cancel key.

Synchronizing is not necessary when the print head was not lifted between print jobs. This also applies if

the printer was powered down between print jobs.

Start a print job.

Start the labelling process via PLC interface.

Error messages during labelling process are shown in the display of the printer

Error Messages.

3.2

Cleaning

!

Attention!

Never use solvent and abrasive.

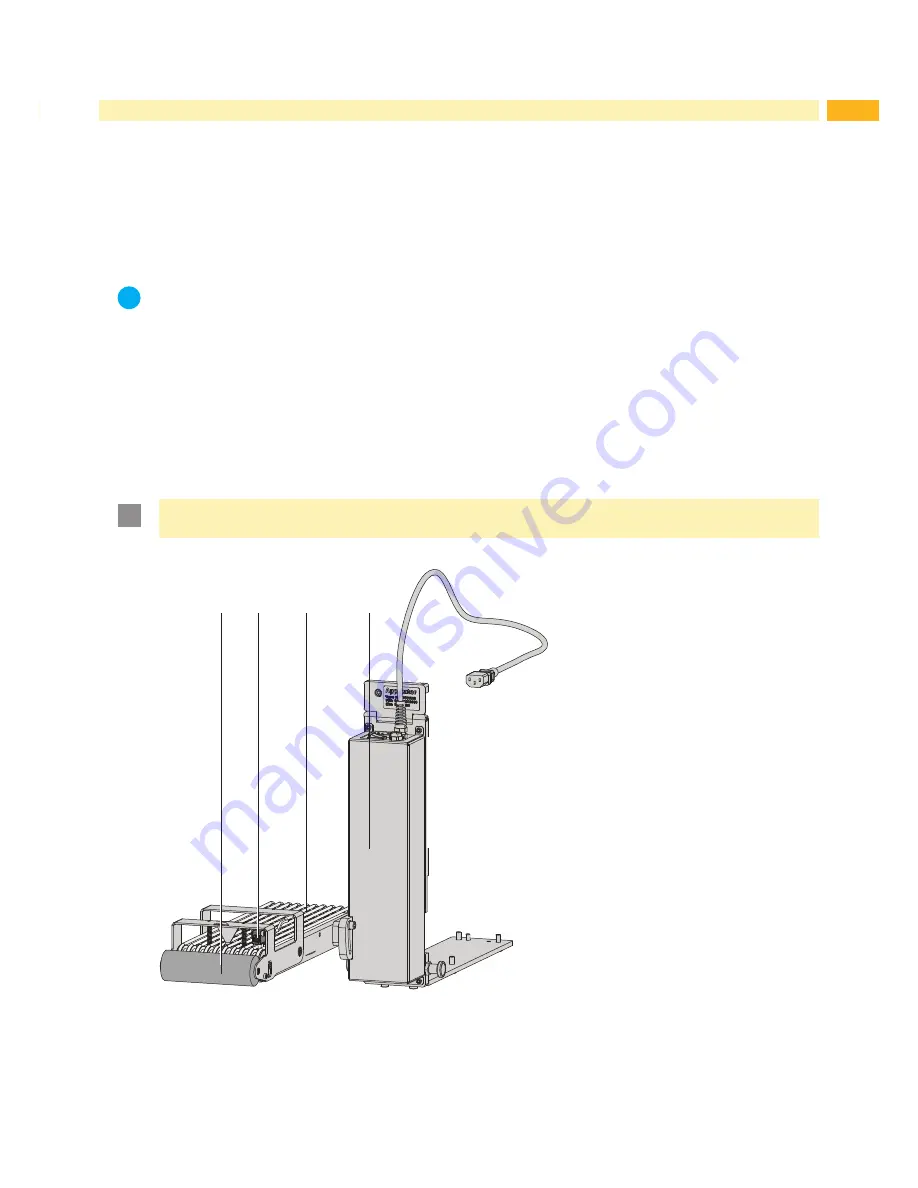

1

2

3

4

1: Clean the pressure roller with multi

purpose cleaner.

2: Use glass cleaner to clean the reflex

sensor.

3: Clean the fan area with a soft brush

and/or a vacuum cleaner.

4: Clean the outside surfaces and

transport belts with a multi purpose

cleaner.

Fig.4

Cleaning