18

TROUBLESHOOTING

C-Dax Ltd and their distributors have a comprehensive parts inventory and capable service staff.

Repairs should only be undertaken by C-Dax, or an authorised C-Dax service center.

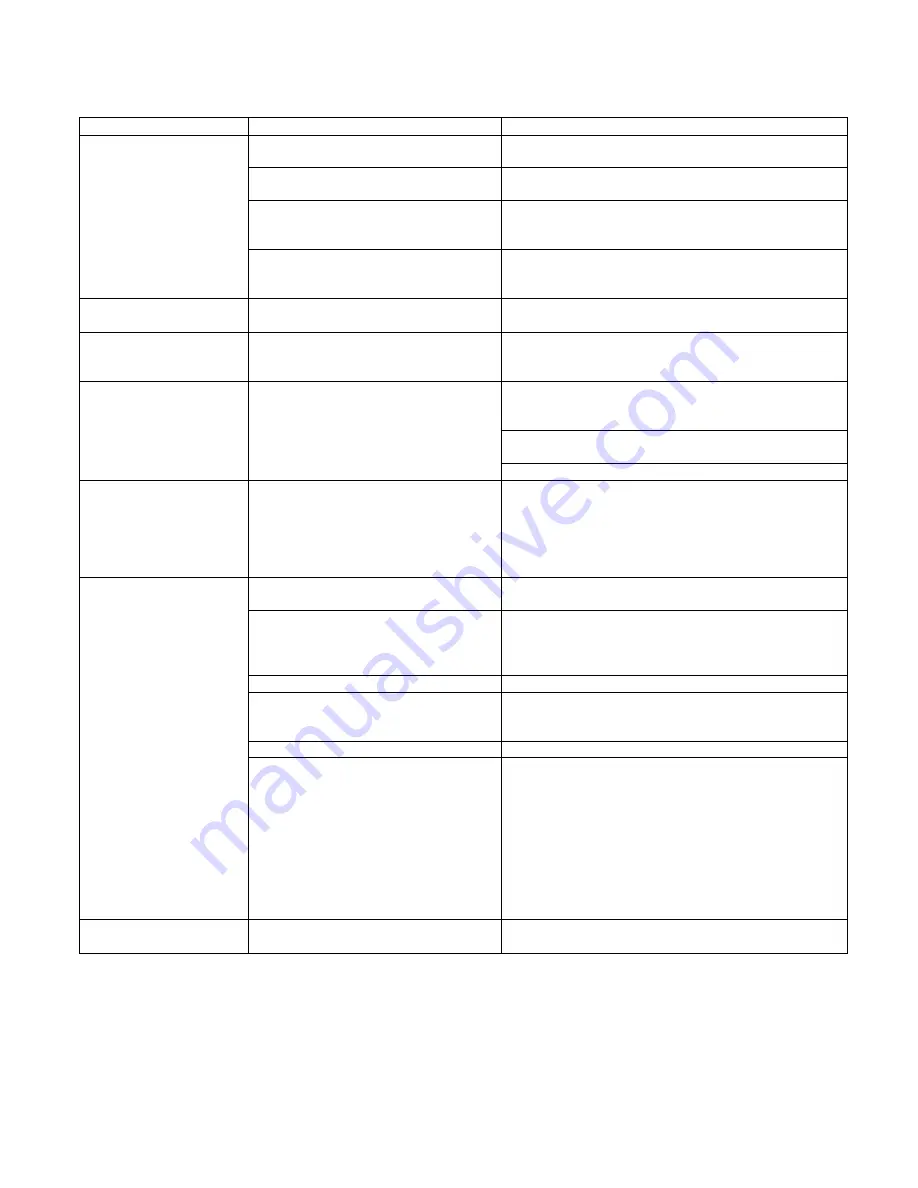

Symptom

Possible causes (procedure)

Probable solution

Pump does nothing

(makes no noise)

Blown fuse (check wiring for shorting

and inspect fuse)

Repair/replace faulty wiring or 15A fuse as

necessary

Loose/intermittent connection (check

all wiring and connections)

Check all wiring and connectors to ensure solid

connection

On/Off switch failed (remove switch

from handle bar, bridge the 2 spade

terminals using a screw driver)

Replace switch if using the screw driver causes

pump to work

If all above fails, likely cause is pump

failure

Take in to local dealer or send to C-Dax for repair.

Be sure to include sufficient paperwork detailing the

problem.

Pump runs for few

seconds then stops

Pump has primed and pressure

switch has activated (this is normal)

No fault, squeeze spray trigger and use as per usual

Fluid leaks from drain

holes in pump

Internal leak within pump head

Take in to local dealer or send to C-Dax for repair.

Be sure to include sufficient paperwork detailing the

problem.

Tank empties from

one leg only

One of the filter valves are not sealing

off properly (Inspect the filter valve at

the base of each leg)

1. Unscrew the nut that holds the filter valve on to the

bottom of the leg. Clean filter thoroughly but carefully

using hose.

2. Check the hose that connects to the filter valve for

splits at bottom. If split found: replace hose.

3. If all above fails, replace filter valve(s)

Tank only partially

empties

One of the internal suction hoses has

developed a leak.

Remove lid and inspect internal suction hoses. The

split/hole will be at the same level as the fluid. You

may need to detach the hoses from the black cross-

fitting at the top of the tank and extract by removing

the filter valve at the bottom of the leg (be sure to

empty tank first).

Pump runs but does

not spray (or sprays

but with little

pressure)

Air lock in pump

Operate spray gun trigger until all air is expelled from

the pump and hose (may take a few moments)

Air leak in suction line

Inspect the suction line (between the tank and pump)

for signs of split hoses and loose clamps. Replace

split hose if required and ensure all clamps are done

up tight.

Blocked suction filter valves

Inspect filter valves and clean if necessary

Air lock in suction line

Pop up the blue/white vacuum release valve on top

of the tank and press it down again (ensure this

valve is screwed on to the black fitting tightly).

Dirt or spray residue in pump valves

Replace valves inside pump

Pump fails to prime (usually on very

first use)

Remove the blue/white vacuum release valve on top

of the tank by carefully unwinding it from the black

fitting (ensure the black fitting stays attached to the

tank). Now force water (from a garden hose) down

the black fitting while the pump is running, this

should force the pump to prime. Screw the

blue/white vacuum release valve back on to the

black fitting tightly and pop the valve down. This

should prime the pump and make the sprayer

operate as per normal.

Pump sprays but does

not stop spraying

Spray gun trigger open

No fault, close trigger

Содержание SPRAYRIDER Generation 2

Страница 19: ...19 SR50 80 PARTS DIAGRAM...

Страница 22: ...22 SR35 PARTS DIAGRAM...