4.

OPERATION RECOMMENDATIONS

Important

A drainage system must be installed in the floor at the lowest point of the equipment room to drain away

water that could be introduced in the event of failure of, or leakage from, a component of the hydraulic

system. This system must be capable of draining away the water in a reasonable amount of time given the

type of equipment installed in the room

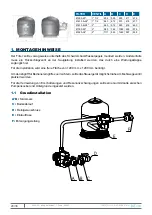

When starting up the filter for the first time, observe the direction in which the water is flowing: in the

“Filtration” position, water should pass though the filter from the top to the bottom. If the pipes were

inverted during assembly, or the multiport valve is defective, water could cross the filter from the bottom to

the top. This would rapidly lead to damage to both the tank and the laterals. The following indicate inverted

assembly:

•

a low pressure reading on the pressure gauge.

•

a flow rate that drops rapidly even after back washing the filter even though the filter basket is clean.

•

persistently cloudy pool water.

Filter run times

The filter run time corresponds to the theoretical time taken for all the pool water to pass through the filter.

In family pools, the recommended run time is 6 hours minimum.

We recommend the following as a function of water temperature:

•

below 14° C: 5 to 6 hours per day.

•

from 15° to 23° C: 6 to 8 hours per day.

•

above 23° C: 10 to 12 hours per day.

The filter run time should be increased with increasing temperature and/or with increasing pool use.

To optimise filtration, run the filter only during the day (between 8 am and 9 pm), and generally while the

pool is in use. (One swimmer pollutes 3m

3

of water).

4.1

Backwashing the filter

Before using the filter for the first time, carry out a backwash to clean it and remove any excess sand or

impurities.

After backwashing the filter, change the valve position to filtration and switch the pump on. The black hand

on the pressure gauge will indicate the filter's nominal pressure. This pressure varies depending on the

pump flow rate, static pressure and pressure drops across the piping.

To preserve a record of this nominal pressure, turn the dial of the pressure gauge until the blue

hand is aligned with the black one.

After a certain time, a drop in the flow rate may be noted at the return fittings. This is caused by the gradual

build up of impurities in the filter or the filter basket.

20/36

CONSTRUCTION & RÉNOVATION

2021/01 - Indice de révision : I - Code : 26680