6

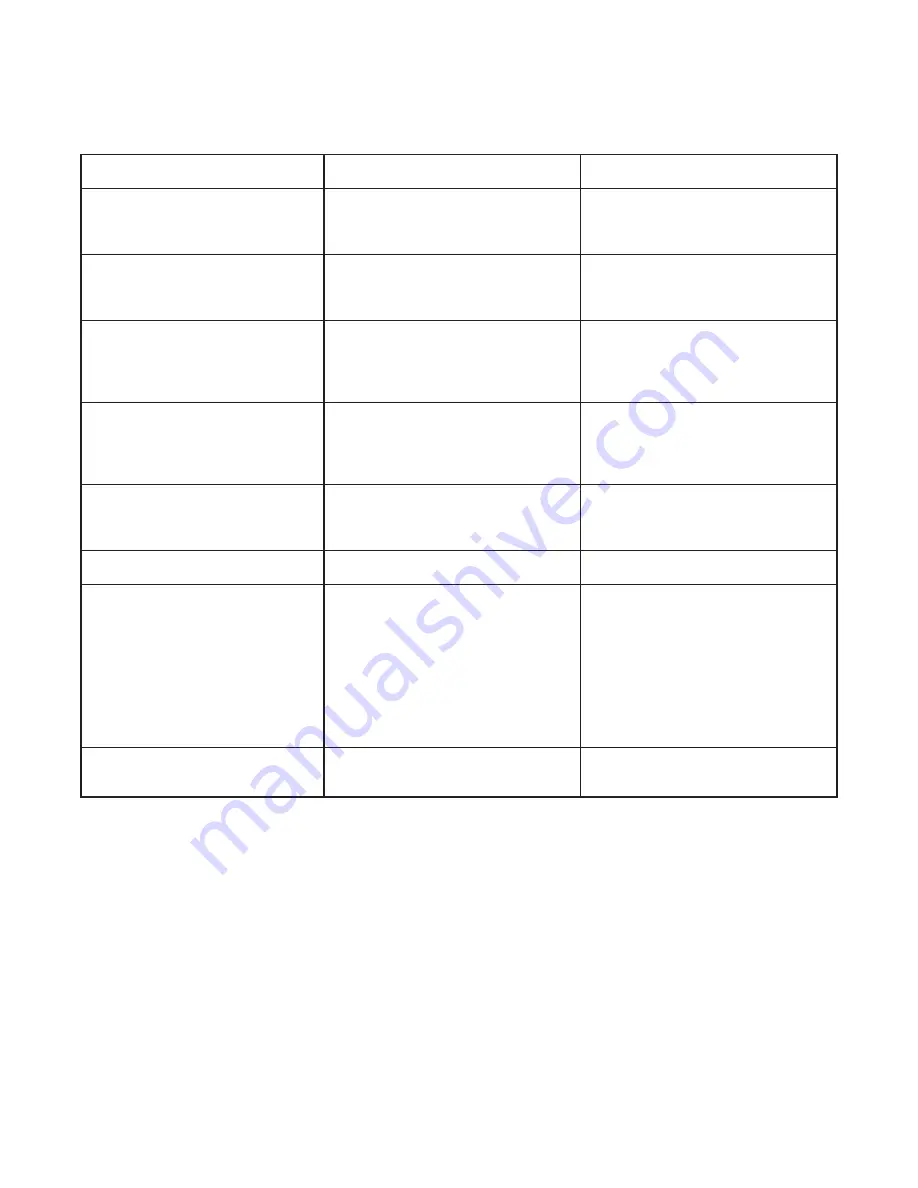

TROUBLESHOOTING GUIDE

The following information is intended as an aid in determining if problem exists. Pump and ram should be repaired only by

authorized BVA Service Center. For repair service, contact service center in your area.

Symptom

Possible Causes

Corrective Action

Erratic action

•

Air in system or pump cavitation.

• External leakage in ram.

• Ram sticking or binding.

• Vent the system.

• Contact service center.

• Contact service center.

Ramr will not extend, or

respond to pressurized fluid

•

Overload condition.

• Loose/Faulty couplers.

• Oil level in pump is low.

• Remedy overload condition.

• Tighten/Replace couplers.

• Fill and bleed the system.

Ram extend only partially

• Oil level in pump is low.

•

Overload condition.

• Ram is sticking or binding.

• Pump malfunction.

• Fill and bleed the system.

• Remedy overload condition.

• Contact service center.

• Contact service center.

Ram move slower than normal

• Loose connection or coupler.

• Restricted hydraulic line or fitting.

• Pump not working correctly.

• Ram seals leaking.

• Tighten connection or coupler.

• Clean and replace if damaged.

• Check pump’s operating instructions.

• Contact service center.

Ram responds to pressurized fluid, but

system does not maintain pressure

• Overload condition.

• Pump malfunctioning.

• Ram seals leaking.

• Remedy overload condition.

• Contact service center.

• Contact

service center.

Oil leaking from ram

• Worn or damaged seals.

• Contact service center.

Ram will not retract or retracts slower

than normal

• Malfunctioning coupler, damaged

application.

• Pump reservoir overfilled.

• Ram damage internally.

•

Secure load by other means

.

Depressurize

pump and hoses,

remove application and replace

coupler.

•

Secure load by other means

.

Depressurize

pump and hoses,

remove application, then drain fluid to

proper level.

• Contact service center.

Poor performance

• Oil level in pump is low.

• Air trapped in system.

• Ensure proper oil level.

• Vent the system.