INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 15 of 67

10.2 Lighting

The machine does not require its own lighting for

normal working operations. However, it must be used

in an adequately lit environment.

In case of poor lighting use lamps having total power

of 800/1200 Watt.

10.3 Working area modification

After the delivery, the machine is prearranged to op-

erate on wheel of 50” maximum diameter and a rim

diameter (10” - 30”). It’s also possible to move the tools

column to enlarge the working area from 52” (with rim

diameter of 12” - 32”) and up to 54” (with rim diameter

of 14” - 34”) (see

Fig. 12

)

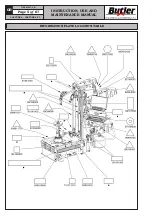

Fig. 12

The column is moved by unloosing the fixing screws of

the base (

Fig. 12 ref. A

) to the column (

Fig. 12 ref. B

)

and by sliding the base (

Fig. 12 ref. A

) itself into the

proper slots until the required measure.

MAKE SURE THAT THE TYRE-

CHANGER COLUMN IS STABLE:

USE A CABLE HELD BY A HOIST

AND HOOK IT TO THE APPROPRI-

ATE LIFTING TRAVERSE (FIG. 13

REF. 7).

1. Remove the lateral guards (

Fig. 13 ref. 1-2

) of the

machine.

2. Unscrew the screws (

Fig. 13 ref. 3

) and the nuts

near the central slots (

Fig. 13 ref. 4

) paying atten-

tion not to remove the nuts from the proper screws.

3. Remove the six remaining screws (

Fig. 13 ref. 5

).

4. Move the base (

Fig. 13 ref. 6

) into the required

position (to 52” or 54”) and if necessary, use a lifting

device (

Fig. 13 ref. 7

).

5. Lock the base three screws (

Fig. 13 ref. 3

) with a

couple of 80 Nm.

6. Place six screws (

Fig. 13 ref. 5

) previously removed

and lock them on the bases side with a couple of

80 Nm.

7. Assemble again the lateral guards (

Fig. 13 ref. 1-2

)

of the machine.

AFTER THE ASSEMBLY, CHECK

THE CORRECT POSITION OF THE

TOOLS. LOCK THE RIM ON THE

MANDREL CENTRE. WITH THE

LOWER BEAD BREAKER ARM,

CHECK THAT THE DISTANCE BE-

TWEEN THE ROLL AND THE RIM

EDGES (UPPER AND LOWER) IS

ALMOST THE SAME. REPEAT ALL

THE PROCEDURES STARTING

FROM POINT 1 IF THE DISTANCE

IS NOT THE SAME.

Fig. 13

CAPTURE 4 - CAPTURE 4 FI

7104-M007-4_B