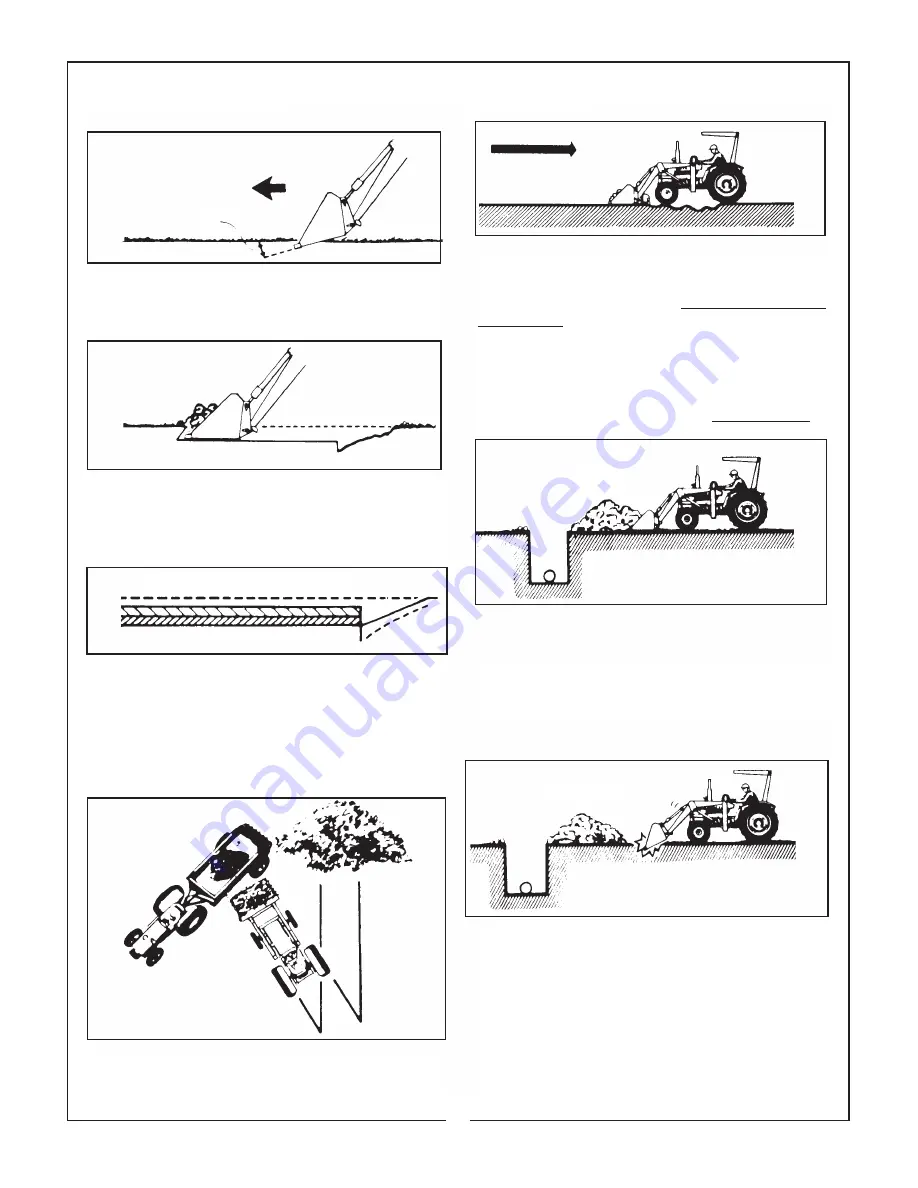

PEELING AND SCRAPING

BACKFILLING

6”

Use a slight bucket angle, travel forward, and hold the

lift control forward to start the cut. Make a short, angle

cut approximately 6” deep and break-out cleanly.

With the bucket level, start a cut at the notch approx-

imately 2” deep. Hold the depth by feathering the

bucket control to adjust the cutting lip up or down.

When the front tires enter the notch, adjust the lift

cylinder to maintain proper depth.

3RD CUT , 4TH CUT, ETC.

Make additional passes until the desired depth is

reached. During each pass, only use the bucket con-

trol while at working depth. This will allow you to

concentrate on controlling the bucket angle to main-

tain a precise cut.

LOADING LOW TRUCKS OR SPREADERS FROM

A PILE

For faster loading, minimize the angle of turn and

length of run between pile and spreader.

Backgrade occasionally with a loaded bucket to

keep the working surface free of ruts and holes.

Hold the lift control forward in float position so the

full weight of the bucket is scraping the ground.

Use only the heel of the bucket while backgrading.

IMPORTANT: To prevent damage to cylinders:

(1) Do not backgrade with bucket cylinders extended.

(2) Always backgrade with valve in float position.

DO THIS

Approach the pile with a flat bucket.

NOT THIS

Poor methods actually move no more dirt and make

it more difficult to hold a level grade.

Do not use the bucket in the dumped position for

bulldozing or backgrading. This method, shown

above, will impose severe shock loadings on the

dump linkage, the bucket cylinder, and the tractor.

16