3-6 LOADER MOUNTED SERIES CON-

TROL VALVE EQUIPPED WITH SINGLE

LEVER CONTROL HANDLE

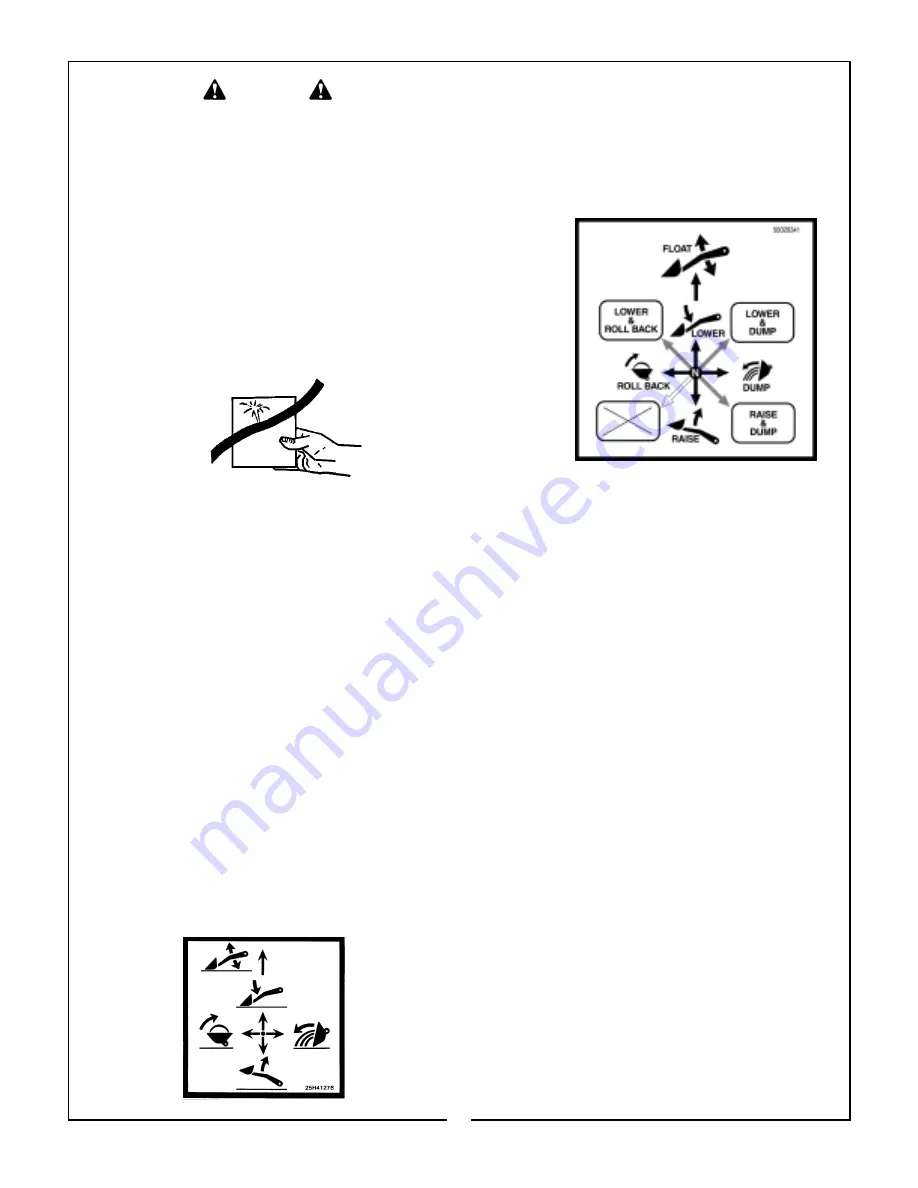

If your loader utilizes a loader mounted series con-

trol valve equipped with single lever control handle,

it will function as shown in Figure 3-2.

3-4 EXTERNAL LOADER AND/OR TRAC-

TOR VALVE.

NOTE

When properly installed, the tractor remote valve

or external valve control lever/levers will control

the loader hydraulic circuits as described below.

Refer to tractor Operator’s Manual for further

explanation of tractor remote control

lever/levers.

IMPORTANT

Contaminants in hydraulic fluid can cause valve

spools to stick. BE ALERT when operating

loader and follow your tractor Operator’s Manual

hydraulic fluid maintenance schedule.

3-5 LOADER MOUNTED CONTROL

VALVE EQUIPPED WITH SINGLE LEVER

CONTROL HANDLE OR TRACTOR

REMOTE VALVE EQUIPPED WITH SIN-

GLE LEVER CONTROL HANDLE

If your loader utilizes a loader control valve equipped

with single lever control handle or tractor remote

valve equipped with single lever control handle, it will

function as shown in Figure 3-1.

3-7 NEUTRAL POSITION

The loader external valve provided by Bush Hog has

a “neutral position” which prevents movement of the

loader or attachment. When the control handle is

manually released from the work position, the valve

spool will return to the neutral position.

3-8 FLOAT POSITION

The loader external valve provided by Bush Hog has

a “float position” incorporated into the lift cylinder cir-

cuit which allows the loader to float. This float fea-

ture is important for satisfactory operation when

scraping, sweeping, leveling, or any job where it is

necessary to follow the contour of the surface. To

activate the float position, lower the bucket or attach-

ment and push the control handle all the way for-

ward into detent. The valve will stay in float detent

position until the operator manually pulls the control

handle out of detent position to deactivate float.

3-9 LOAD SENSE LOADER VALVE.

IMPORTANT

If your loader is equipped with a load sense type

control valve it may demonstrate the following

operation characteristic. Attempting to raise the

boom by finely feathering the control lever may

actually allow the boom to lower very slowly. To

prevent this from happening, move the control

lever far enough to ensure that the boom raises.

14

ESCAPING HYDRAULIC FLUID UNDER

PRESSURE CAN HAVE SUFFICIENT FORCE

TO PENETRATE SKIN, CAUSING SERIOUS

PERSONAL INJURY. BEFORE APPLYING

PRESSURE TO SYSTEM, BE SURE ALL

CONNECTIONS ARE TIGHT AND THAT

LINES, TUBES, AND HOSES ARE NOT DAM-

AGED. FLUID ESCAPING FROM A VERY

SMALL HOLE CAN BE ALMOST INVISIBLE.

USE A PIECE OF CARDBOARD OR WOOD,

RATHER THAN HANDS, TO SEARCH FOR

SUSPECTED LEAKS. IF INJURED BY

ESCAPING FLUID, SEE A DOCTOR AT

ONCE. SERIOUS INFECTION OR REACTION

CAN DEVELOP IF PROPER MEDICAL

TREATMENT IS NOT ADMINISTERED IMME-

DIATELY.

Figure 3-1

Figure 3-2

WARNING