5-4 FORK LIFT ATTACHMENT

WARNING

TO AVOID SERIOUS INJURY OR DEATH:

★

NEVER LIFT LARGE ROUND HAY

BALES OR OTHER LOADS ON THE

FORK LIFT ATTACHMENT THAT

COULD ROLL BACK ONTO TRAC-

TOR OPERATOR AREA.

★

NEVER USE FORK LIFT ATTACH-

MENT TO LIFT OR SUPPORT

PEOPLE.

★

TRANSPORT LOADS LOW AND

SLOW.

★

AVOID CONTACT WITH POWER

LINES.

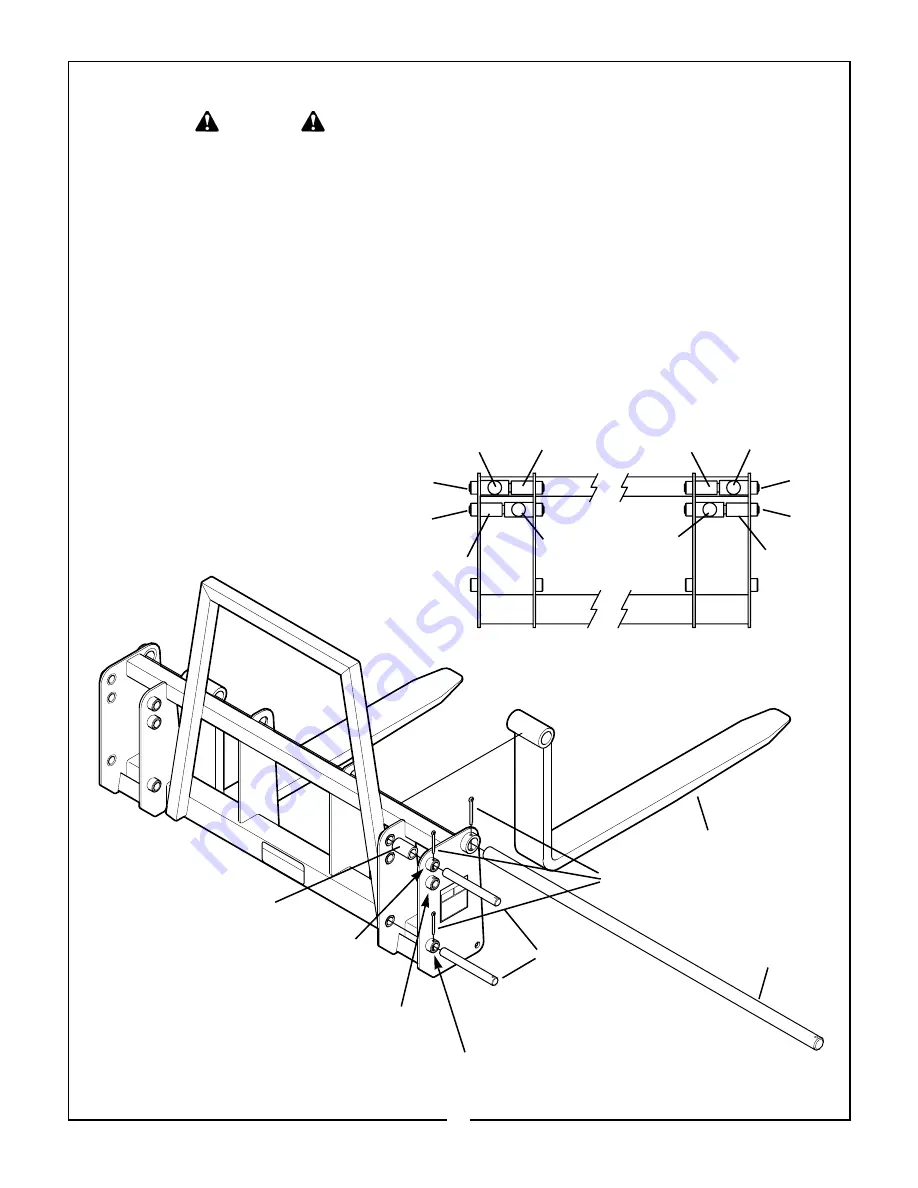

The fork lift attachment (Figure 5-4) is intended for

handling palletized material. It is recommended that

tractor be equipped with ROPS and seat belts. Use

ASSEMBLY

1. Remove all cotter pins.

2. Slide fork pin out enough to place fork tine

between bracket.

3. Slide fork pin through the fork tine and back

through bracket and bushing.

4. Aligh cotter pin holes on fork lift frame and fork

pin and replace bushing.

5. Spread cotter pin so it cannot work free.

6. The loader lifting capacity is approximately 75%

of the rated capacity at 24” from the face of the

fork tine.

Figure 5-4 Fork Lift Attachment

Hydraulic

Cylinder

Hydraulic

Cylinder

Hitch

Bushing

Hitch

Bushing

2246 QT

Position

1846 QT

Position

2246 QT

Position

1846 QT

Position

the loader dump cylinders to give the forks the

desired tilt. Position the forks on their support rods to

the desired width so that the load will be carried

approximately equal on each fork. Position load as

far back as possible.

Hitch

Bushing

Hitch

Bushing

Hydraulic

Cylinder

Hydraulic

Cylinder

NOTE: Position Hydraulic cylinder and Hitch Bushing as shown.

(Fork lift shown from back view)

Fork Tine

Fork Pin

Cotter Pins

Hitch Pins

Hitch Bushing

(See Note)

Place Hitch Pin in this hole to hook up

hydraulic cylinder on 2246 QT Loaders.

Requires Hitch Bushing to position cylinder.

(See Note)

Place Hitch Pin in this hole to hook up hydraulic on

1846 QT Loaders. Requires Hitch Bushing to posi-

tion cylinder. (See Note)

Place Hitch Pin in this hole on 1846 QT & 2246

QT Loaders. No Hitch Bushing required.

21