Storage | 4

0870549537_NC2000B_VR_A0004_IM_en

7 / 28

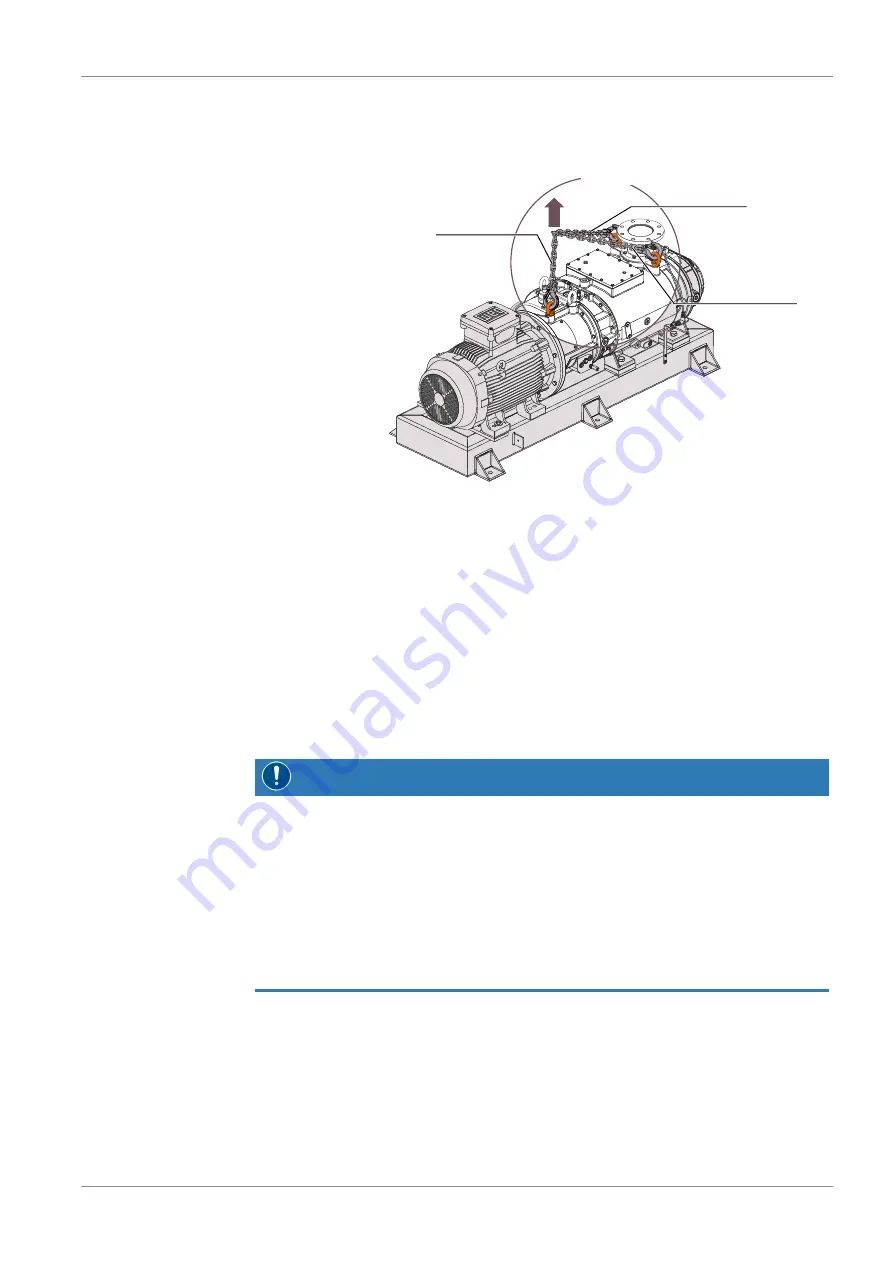

• Make sure that the eyebolt(s) (EB) is/are in faultless condition, fully screwed in and

tightened by hand.

Machine weight:

see the technical data or the nameplate (NP)

l3 = ~1030 mm

l1 = ~770 mm

l2 = ~1020 mm

• Check the machine for transport damage.

If the machine is secured to a base plate:

• Remove the machine from the base plate.

4

Storage

• Seal all apertures with adhesive tape or reuse provided caps.

If the machine is to be stored for more than 3 months:

• Wrap the machine in a corrosion inhibiting film.

• Store the machine indoors, dry, dust free and if possible in original packaging

preferably at temperatures between -20 ... 60 °C.

NOTICE

Long storage time.

Risk of damage to the machine!

• If the machine is equipped with oil lubricated mechanical seals, we recommend to

completely fill the oil chamber before a long storage, see “Oil filling” in chapter

. This protects the mechanical seals during a long storage. Use the

standard pump oil, see chapter

• Before restarting the machine, drain the oil to the normal oil level, see “Oil draining”

.