38

Fluid installation

Type 8745 Ethernet, 8745 Analogue

7.4

Product variant with NPT-internal-

threaded connections

WARNING

risk of injury that is due to leakage.

▶

At a low mass flow rate and a high pressure, make sure

that the installation is tight. The tightness prevents incorrect

measurements or the leakage of the operating fluid.

To make sure that the installation is tight, observe the following

instructions:

▶

Use compression fittings. Mount the compression fittings, in

a way that they are not subject to any stresses.

▶

Use pipes with a diameter that is adapted to the fluid con

-

nection of the product, and with a smooth surface.

No inlet section is required.

→

Remove all dirt from the pipes and from the fluid carrying

components of the installation.

→

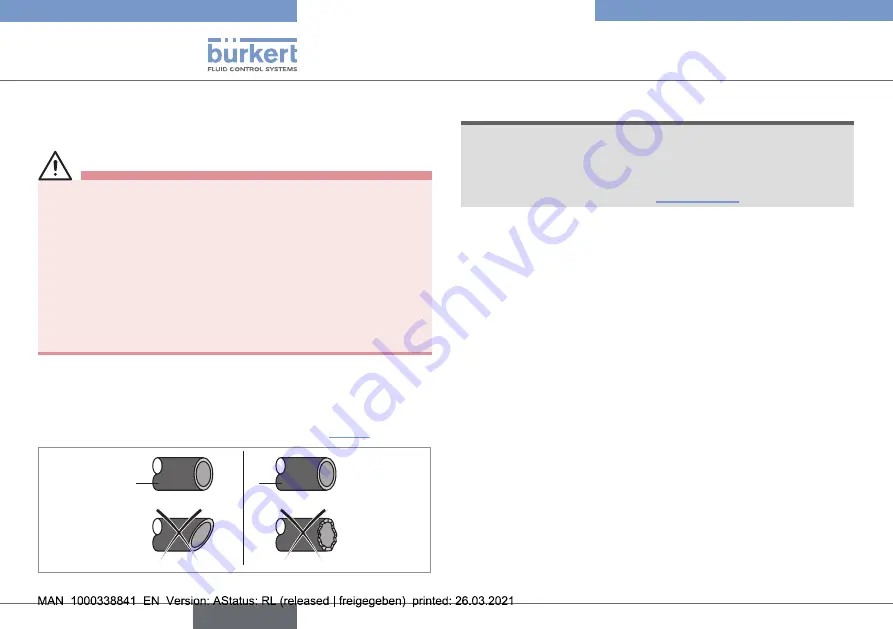

Cut the pipe squarely [

1

] and deburr [

2

1

2

Fig. 22: Pipe cut and deburred

NOTICE

malfunction that is due to contamination.

▶

If a contaminated operating fluid is used, then install a

filter upstream of the product. The filter mesh-size must be

smaller than 25 µm. The filter ensures problem-free function

-

ing of the product. See chpt.

→

Observe the installation position that is given on the cali

-

bration plate or in the calibration protocol.

→

Remove the protective cap that closes the threaded

connection.

→

Do the fluid connection on one side of the product.

→

Obey the instructions that are given by the manufacturer of

the fitting used.

→

Obey the torques that are given by the manufacturer of the

fitting used.

→

Do the fluid connection on the other side of the product in the

same way.

English

Содержание 8745 MFC Ethernet

Страница 69: ......

Страница 70: ...www burkert com...