6

© BTB Auto Glass & Body Shop Tools

2. Cut-Out Guidelines & Examples

2.1 Blade Types, Blade Usage, Blade Depth

Control

Details of BTB's full product range can be found in our dedicated

Removal System catalogue supplied with the power tool, and

available for viewing or downloading from BTBTOOLS.COM.

A training video can also be viewed from this website.

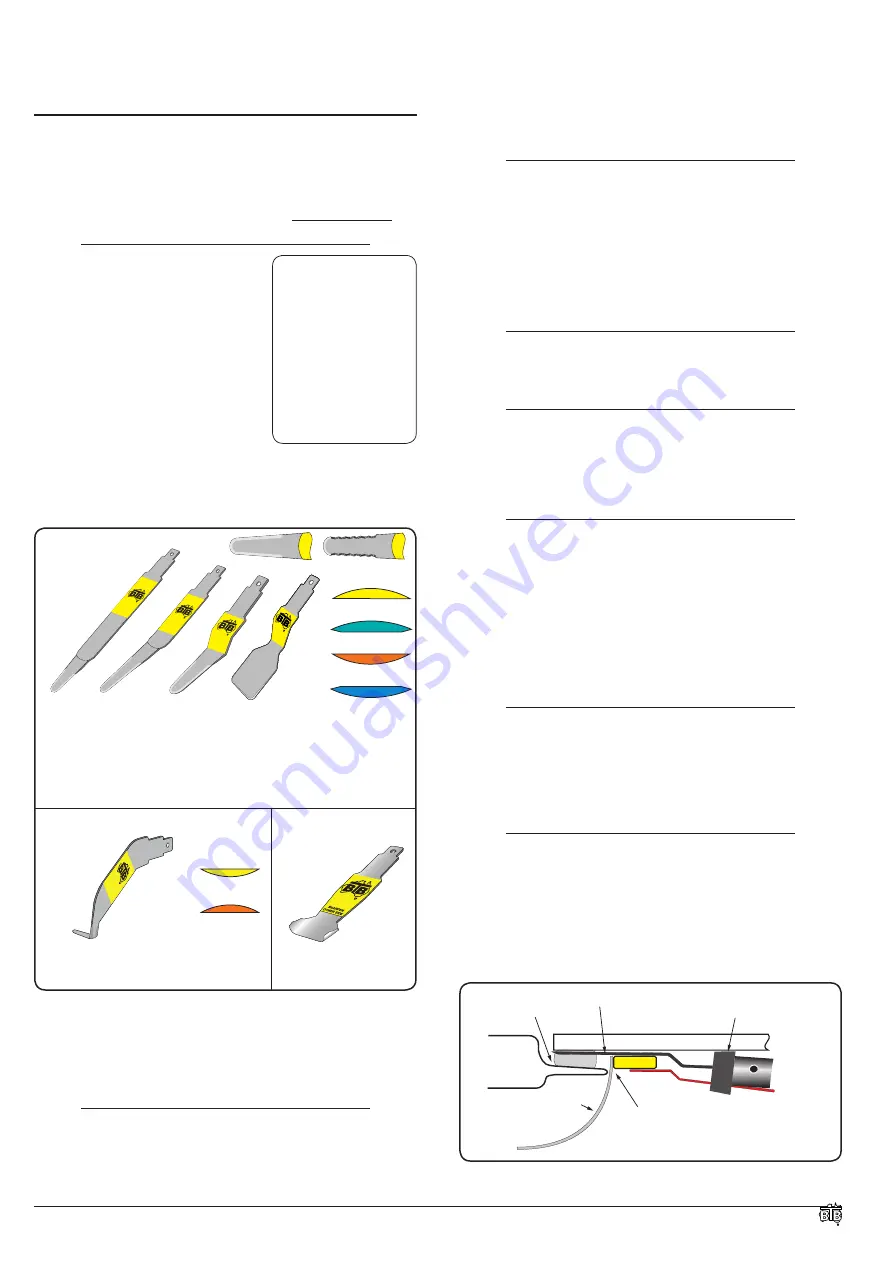

2.1.1 SIX BASIC BLADE TYPES

• Standard Straight Blades

• Standard Bent Blades

• Standard "Z" Blades

• Standard Spade "Z" Blades

• Powered Cold Knife Blades

• Winged Scraper Blades

Variations of these include:

• Length up to 375 mm

• Flexibility of blade tip

• Serrated or Non-Serrated

• Cutting Tip Length of PCK blades

• Wing Width of Scraper Blades

• Cutting Tip Profile (

designated by colour, see below

)

serrated

GREEN 'V'

ORANGE 'R'

YELLOW

BLUE 'VR'

straight

bent

Z style

spade

Yellow

or

Green

blades have the flat side of their cutting tip down.

Green

'V' blades are a safety edge version of the yellow blades

Orange

or

Blue

(reverse) blades have the flat side of their cutting

tip up (bent opposite to Yellow and Green blades).

Blue

'V' blades

are a safety edge version of the orange blades.

ORANGE 'R'

YELLOW

Powered Cold Knife (PCK) Blades Winged Pinchweld

Scraper Blades

Yellow

blades have the flat side of their

cutting tip up.

Orange

blades have the

flat side of their cutting tip down.

Radius grind of cutting

tip won't scratch

vehicle paintwork.

non-serrated

Standard Blades

Diagram D

2.1.1.1 STANDARD NON-SERRATED AND SERRATED BLADES

Non-Serrated

blades can be used in all glass and panel applications.

Serrated

blades are optional and can provide a faster more

aggressive cutting action.

2.1.2 Fitting and Changing Blades in the Power Tool

To fit blades, always turn power switch to the OFF (right) position

or disconnect the power cord. Using the 4.0mm

WKKEY

Allen key

provided, unscrew the

SPB33

cone point retaining screw (located

Refer to Diagram A

on page 2 and Section

2.2 on

page 7

to plan

your cut out.

Refer to Hints, Tips and

Operating Techniques

on

page

14

for further

blade use guidelines.

A full blade list can be

found on

page

15

.

via the hole in the controller cap) two full rotations counter

clockwise. Insert the blade as far as it will go into the chuck and

firmly re-tighten retaining screw in clockwise motion. Check that

the blade is securely held before reconnecting or turning on power.

NOTE:

All blades will also fit in the WK7 and WK7L manual handles.

2.1.3 Sharpening Blades

The best cutting results are obtained with sharp blades. The

procedure for sharpening the blades is as follows:

1. Sharpen blades from radiused (rounded) side only.

2. Keep flat side of blade smooth to allow sliding motion on the

glass surface.

WARNING:

COARSE GRINDING OR BLUNT BLADES WILL SERIOUSLY

REDUCE PERFORMANCE, EFFICIENCY AND SAFETY.

2.1.4 Replace Worn Blades

If shape / length of blade tip reduces from repeated sharpening, or

is varied from its original shape, replace blade to regain efficiency.

2.1.5 Cutting Lubricant is Important

Using Cutting lubrication is important for blade movement. Always

spray both the inside and the outside of the glass where possible.

Use water or a cutting lubricant / additive mixed with water that has

been

approved

by your adhesive manufacturer.

2.1.6 Blade Vibration When Cutting Internally

If a blade vibrates or flaps against the glass, the operator is doing

something wrong. Refer to the following points 1, 2 and 3 below

and also

Diagrams J, K

and

Diagram L

.

1. Check blade tip is flat against the glass or panel.

2. Ensure blade and tool are held firm, the angle is correct, and the

controller cap is against the glass.

3. When cutting below dashboard with long blade, keep tool and

blade in straight line. See

Diagram L

and

Diagram M

.

2.1.7 Protect Glass and Painted Panel Surfaces

As an extra precaution to avoid scratching the glass with the back

of the cutting blade, you can apply a small Velcro® pad (supplied

in kits) to the offending section of the blade. Ensure the blade is

dry. The

WK11PP

paint protector controller arm can be used in

conjunction with external Powered Cold Knife blades.

2.1.8 Rest the Nylon Controller Cap Against the Glass

The nylon controller cap will not scratch glass or panel and is to

be held against the glass surface for internal cutting. This also

guarantees efficient cutting and operator control because the blade

and cutting tip is held at the correct angle and hugging the glass

surface. It is also designed to attach blade cutting depth controller

arms. See also

2.1.9 Adjustable Cutting Depth Controller Arms (page 7).

WK11BW5 CONTROLLER ARM

WHEEL STOPS AT PILLAR TRIM

INTERIOR ROOF LINER

OR PILLAR TRIM

CAR

BODY

Z BLADE

GLASS

NYLON CONTROLLER CAP

RESTS AGAINST GLASS SURFACE

ADHESIVE

Diagram E