26

Dirty Sensor Test Using an SD-TRK4

1. Turn the key switch to the RESET/TEST position for two

seconds.

2. Verify that the test/reset station’s Trouble LED flashes.

Detector Cleaning

CLEANING THE SMOKE DETECTOR

Clean the duct smoke sensor when the Dirty LED is flashing

continuously or sooner if conditions warrant.

1. Disconnect power from the duct detector, then remove the

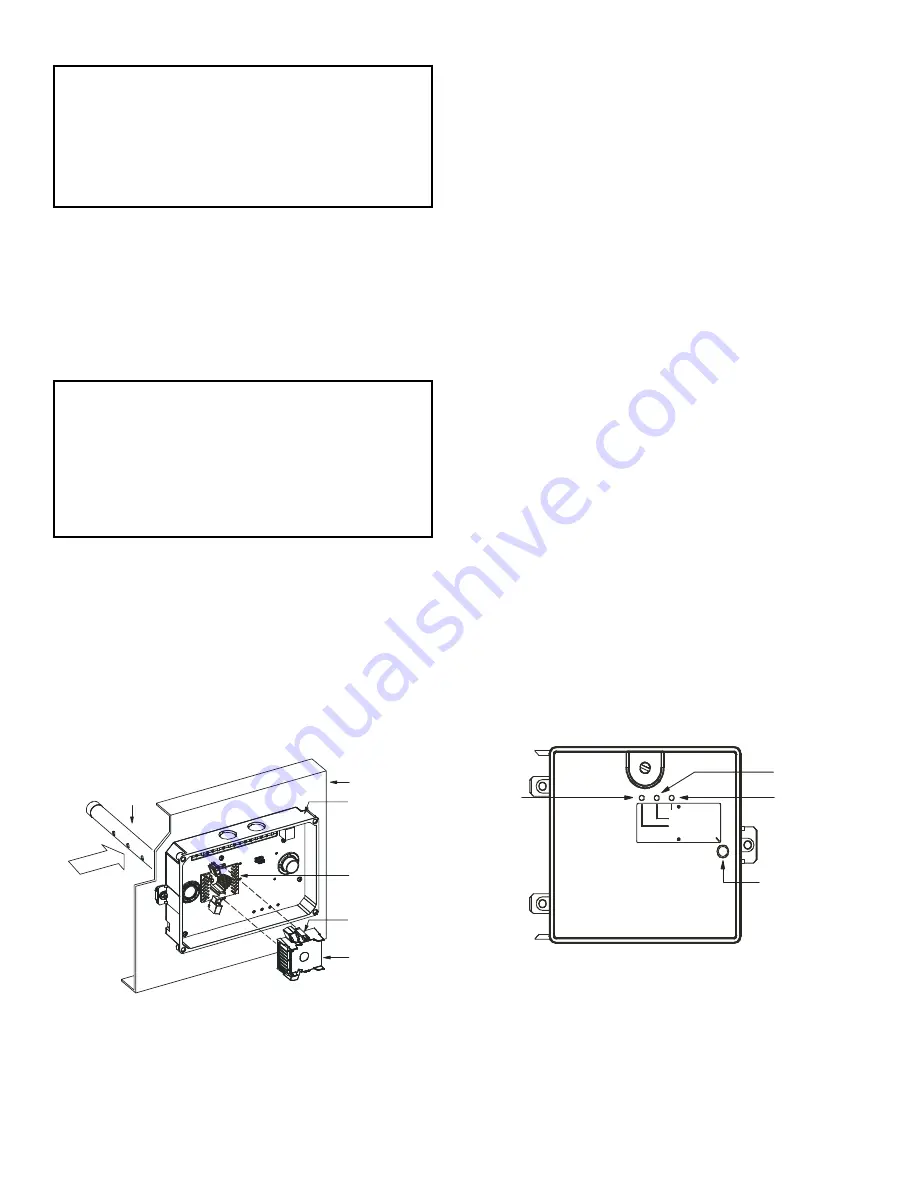

sensor’s cover (see Fig. 44).

2. Using a vacuum cleaner, clean compressed air, or a soft

bristle brush, remove loose dirt and debris from inside the

sensor housing and cover. Use isopropyl alcohol and a

lint-free cloth to remove dirt and other contaminants from

the gasket on the sensor’s cover.

3. Squeeze the retainer clips on both sides of the optic housing.

4. Lift the housing away from the printed circuit board.

5. Gently remove dirt and debris from around the optic plate

and inside the optic housing.

6. Replace the optic housing and sensor cover.

7. Connect power to the duct detector, then perform a sensor

alarm test.

Fig. 44 — Sensor Cleaning Diagram

Indicators

NORMAL STATE

The smoke detector operates in the normal state in the absence

of any trouble conditions and when its sensing chamber is free

of smoke. In the normal state, the Power LED on both the sen-

sor and the controller are on and all other LEDs are off.

ALARM STATE

The smoke detector enters the alarm state when the amount of

smoke particulate in the sensor’s sensing chamber exceeds the

alarm threshold value. (See Table 8.) Upon entering the alarm

state:

• The sensor’s Alarm LED and the controller’s Alarm LED

turn on.

• The contacts on the controller’s two auxiliary relays switch

positions.

• The contacts on the controller’s alarm initiation relay

close.

• The controller’s remote alarm LED output is activated

(turned on).

• The controller’s high impedance multiple fan shutdown

control line is pulled to ground Trouble state.

The SuperDuct smoke detector enters the trouble state under

the following conditions:

• A sensor’s cover is removed and 20 minutes pass before it

is properly secured.

• A sensor’s environmental compensation limit is reached

(100% dirty).

• A wiring fault between a sensor and the controller is detected.

An internal sensor fault is detected upon entering the trouble

state:

• The contacts on the controller’s supervisory relay switch

positions (see Fig. 45).

• If a sensor detects trouble, the sensor’s Trouble LED the

controller’s Trouble LED turns on.

• If 100% dirty, the sensor’s Dirty LED turns on and the

controller’s Trouble LED flashes continuously.

• If there is a wiring fault between a sensor and the control-

ler, the controller’s Trouble LED turns on, but not the sen-

sor’s LED.

Fig. 45 — Controller Assembly

NOTE: All troubles are latched by the duct smoke detector. The

trouble condition must be cleared and then the duct smoke detec-

tor must be reset in order to restore it to the normal state.

IMPORTANT: OPERATIONAL TEST ALERT

Failure to follow this ALERT can result in an unnecessary

evacuation of the facility.

Holding the test magnet against the sensor housing for

more than seven seconds will put the duct detector into the

alarm state and activate all automatic alarm responses.

IMPORTANT: OPERATIONAL TEST ALERT

Failure to follow this ALERT can result in an unnecessary

evacuation of the facility.

If the smoke detector is connected to a fire alarm system,

first notify the proper authorities that the detector is under-

going maintenance, then disable the relevant circuit to

avoid generating a false alarm.

HVAC DUCT

SAMPLING

TUBE

RETAINER

CLIP

OPTIC

PLATE

OPTIC

HOUSING

SENSOR

HOUSING

AIRFLOW

ALARM

POWER

TEST/RESET

SWITCH

TROUBLE

RESET

ALARM

TROUBLE

POWER

Содержание Preferred 581J04-14

Страница 36: ...36 Fig 60 Integrated Gas Control IGC Board RED LED STATUS ...

Страница 44: ...44 Fig 65 RTU Open Overlay for Economizer Wiring ...

Страница 45: ...45 Fig 66 VFD Overlay for W2770 Controller Wiring ...

Страница 96: ...96 Fig B 581J 04 06 YAC Control Diagram 208 1 60 208 230 3 60 460 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 99: ...99 Fig E 581J 07A B C YAC Control Diagram 208 230 3 60 460 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 100: ...100 Fig F 581J 08 09 YAC Control Diagram 208 230 3 60 460 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 101: ...101 Fig G 581J 11YAC Control Diagram 208 230 3 60 460 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 102: ...102 Fig H 581J 12 YAC Control Diagram 208 230 3 60 460 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 103: ...103 Fig I 581J 04 06 YAC Power Diagram 208 230 1 60 APPENDIX D WIRING DIAGRAMS ...

Страница 104: ...104 Fig J 581J 04 06 YAC Power Diagram 208 230 3 60 460 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 105: ...105 Fig K 581J 04 06 YAC Power Diagram 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 106: ...106 Fig L 581J 07 12D F YAC Power Diagram 208 230 3 60 460 3 60 6 Ton 2 Stage with Cooling APPENDIX D WIRING DIAGRAMS ...

Страница 108: ...108 Fig N 581J 07 12A B C YAC Power Diagram 208 230 3 60 460 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 109: ...109 Fig O 581J 07 12A B C YAC Power Diagram 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 110: ...110 Fig P 581J 08 09 YAC Power Diagram 230 460 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 111: ...111 Fig Q 581J 08 09 YAC Power Diagram 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 112: ...112 Fig R 581J 11 YAC Power Diagram 208 230 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 113: ...113 Fig S 581J 11 YAC Power Diagram 460 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 114: ...114 Fig T 581J 11 YAC Power Diagram 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 115: ...115 Fig U 581J 12 YAC Power Diagram 230 460 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 116: ...116 Fig V 581J 12 YAC Power Diagram 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 117: ...117 Fig W 581J 14 YAC Control Diagram 208 230 3 60 460 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 118: ...118 Fig X 581J 14 YAC Power Diagram 208 230 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 119: ...119 Fig Y 581J 14 YAC Power Diagram 460 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 120: ...120 Fig Z 581J 14 YAC Power Diagram 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Страница 121: ...121 Fig AA 581J 04 06 YAC Control Diagram 230 1 60 230 460 575 3 60 with Dehumidification APPENDIX D WIRING DIAGRAMS ...

Страница 122: ...122 Fig AB 581J 07A B C YAC Control Diagram 230 1 60 230 460 575 3 60 with Dehumidification APPENDIX D WIRING DIAGRAMS ...

Страница 123: ...123 Fig AC 581J 08 09 YAC Control Diagram 230 460 575 3 60 with Dehumidification APPENDIX D WIRING DIAGRAMS ...

Страница 124: ...124 Fig AD 581J 11 YAC Control Diagram 230 1 60 230 460 575 3 60 with Dehumidification APPENDIX D WIRING DIAGRAMS ...

Страница 125: ...125 Fig AE 581J 12 YAC Control Diagram 230 460 575 3 60 with Dehumidification APPENDIX D WIRING DIAGRAMS ...

Страница 126: ...126 Fig AF 581J 04 06 YAC Power Diagram 208 230 1 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 127: ...127 Fig AG 581J 04 06 YAC Power Diagram 230 460 3 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 128: ...128 Fig AH 581J 04 06 YAC Power Diagram 575 3 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 129: ...129 Fig AI 581J 07A B C YAC Power Diagram 230 460 3 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 130: ...130 Fig AJ 581J 07A B C YAC Power Diagram 575 3 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 131: ...131 Fig AK 581J 08 09 YAC Power Diagram 230 460 3 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 132: ...132 Fig AL 581J 08 09 YAC Power Diagram 575 3 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 133: ...133 Fig AM 581J 11 YAC Power Diagram 208 230 3 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 134: ...134 Fig AN 581J 11 YAC Power Diagram 460 3 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 135: ...135 Fig AO 581J 11 YAC Power Diagram 575 3 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 136: ...136 Fig AP 581J 12 YAC Power Diagram 230 460 3 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 137: ...137 Fig AQ 581J 12 YAC Power Diagram 575 3 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 138: ...138 Fig AR 581J 14 YAC Control Diagram 230 460 575 3 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 139: ...139 Fig AS 581J 14 YAC Power Diagram 208 230 3 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 140: ...140 Fig AT 581J 14 YAC Power Diagram 460 3 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 141: ...141 Fig AU 581J 14 YAC Power Diagram 575 3 60 with Perfect Humidity System APPENDIX D WIRING DIAGRAMS ...

Страница 142: ...142 Fig AV YAC Direct Digital System Control Wiring Diagram System 50HE500891 F APPENDIX D WIRING DIAGRAMS ...

Страница 143: ...143 Fig AW RTU Open Wiring Diagram APPENDIX D WIRING DIAGRAMS ...