935CA: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

22

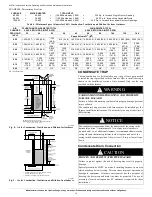

1.Nominal 350 CFM/ton cooling airflow is delivered with SW1-5 and SW4-3 set to OFF.

Set SW1-5 to ON for nominal 400 CFM/ton (+15% airflow).

Set SW4-3 to ON for nominal 325 CFM/ton (-7% airflow).

Set both SW1-5 and SW4-3 on ON for nominal 370 CFM/ton (+7% airflow).

The above adjustments in airflow are subject to motor horsepower range/capacity

This applies to Cooling and Low-Cooling airflow, but does not affect continuous fan airflow.

2.Maximum cooling airflow is achieved when switches SW2-3, SW2-2, SW2-1 and SW1-5 are set to ON, and SW4-3 is set to OFF.

3.All heating CFM's are when comfort/efficiency adjustment switch (SW1-4) is set to OFF

4.Ductwork must be sized for high-heating CFM within the operational range of ESP. Operation within the blank areas of the chart is not recommended because heat operation will be above

1.0 ESP.

5.All airflows on noted 21" (533 mm) casing size furnaces are 5% less on side return only installations.

6.Side returns for noted models, require two sides, or a side and bottom to allow sufficient airflow at the return of the furnace.

7.Airflows over 1800 CFM require bottom return, two-side return, or bottom and a side return or excessive watt draw may result. A minimum filter size of 20 x 25” (508 x 635 mm) is

required.

COOLING

4

AND HEATING AIR DELIVERY - CFM (Bottom Return With Filter)

(SW1-5 and SW4-3 set to OFF, except as indicated. See notes 1 and 2)

Unit Size:

30080C21

5

Clg/CF Switch settings

External Static Pressure (ESP)

Clg Switches:

SW2-3

SW2-2

SW2-1

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Clg Default:

OFF

OFF

OFF

1825

1830

1830

1825

1825

1825

1815

1810

1805

1785

CF Switches

SW3-3

SW3-2

SW3-1

Low-Clg Default:

OFF

OFF

ON

695

700

Note 4

Cooling

(SW2)

Low-Cooling

(SW3)

OFF

ON

OFF

870

885

880

880

Note 4

OFF

ON

ON

1045

1060

1070

1070

1070

1070

Note 4

ON

OFF

OFF

1310

1315

1315

1315

1310

1300

1290

1280

Note 4

ON

OFF

ON

1470

1475

1480

1480

1480

1475

1465

1460

1450

1440

ON

ON

OFF

1825

1830

1830

1825

1825

1825

1815

1810

1805

1785

ON

ON

ON

2170

2180

2180

2175

2170

2150

2080

1995

1915

1825

Maximum Clg Airflow

2

2230

2225

2235

2230

2195

2165

2110

2020

1935

1845

CF Switches

SW3-3

SW3-2

SW3-1

Cont. Fan Default:

OFF

OFF

OFF

695

700

Note 4

Continuous Fan

(SW3)

OFF

OFF

ON

695

700

Note 4

OFF

ON

OFF

870

885

880

880

Note 4

OFF

ON

ON

870

885

880

880

Note 4

ON

OFF

OFF

870

885

880

880

Note 4

ON

OFF

ON

870

885

880

880

Note 4

ON

ON

OFF

870

885

880

880

Note 4

ON

ON

ON

870

885

880

880

Note 4

Heating (SW1)

Heat Airflow

3

1425

1430

1435

1435

1435

1425

1420

1410

1400

1390

Unit Size:

66100C21

6

Clg/CF Switch settings

External Static Pressure (ESP)

Clg Switches:

SW2-3

SW2-2

SW2-1

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Clg Default:

OFF

OFF

OFF

1765

1775

1790

1805

1810

1820

1820

1820

1820

1820

CF Switches

SW3-3

SW3-2

SW3-1

Cooling

(SW2)

Low-Cooling

(SW3)

OFF

OFF

ON

630

Note 4

OFF

ON

OFF

805

830

Note 4

OFF

ON

ON

1065

1075

1080

1085

Note 4

ON

OFF

OFF

1240

1250

1265

1270

1270

Note 4

ON

OFF

ON

1410

1415

1435

1445

1450

1455

1460

Note 4

ON

ON

OFF

1765

1775

1790

1805

1810

1820

1820

1820

1820

1820

ON

ON

ON

2115

2115

2125

2140

2145

2150

2145

2140

2080

1985

Maximum Clg Airflow

2

2165

2185

2200

2215

2225

2240

2250

2210

2120

2030

CF Switches

SW3-3

SW3-2

SW3-1

Cont. Fan Default:

OFF

OFF

OFF

630

Note 4

Continuous Fan

(SW3)

OFF

OFF

ON

630

Note 4

OFF

ON

OFF

805

830

Note 4

OFF

ON

ON

1020

1040

1050

Note 4

ON

OFF

OFF

1020

1040

1050

Note 4

ON

OFF

ON

1020

1040

1050

Note 4

ON

ON

OFF

1020

1040

1050

Note 4

ON

ON

ON

1020

1040

1050

Note 4

Heating (SW1)

Heat Airflow

3

1790

1800

1815

1830

1835

1845

1850

1850

1855

1855

Table 11 – Air Delivery - CFM (With Filter) (Continued)