29

RTU OPEN CONTROL SYSTEM

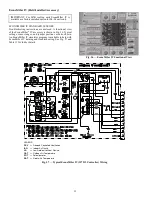

The RTU Open controller is an integrated component of the

Bryant rooftop unit. Its internal application programming

provides optimum performance and energy efficiency. RTU

Open enables the unit to run in 100% stand-alone control mode

or a Third Party Building Automation System (BAS). On-

board DIP switches allow the user to select your protocol (and

baud rate) of choice among the four most popular protocols in

use today: BACnet, Modbus

1

, Johnson N2 and LonWorks

2

.

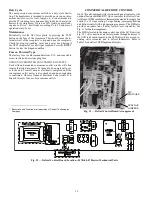

See Fig. 51.

The RTU Open control is factory-mounted in the unit’s main

control box, to the left of the UCB (unit control board). Factory

wiring is completed through harnesses connected to the UCB.

Field connections for RTU Open sensors will be made at the

PCB connectors on the RTU Open board. The factory-installed

RTU Open control includes the supply-air temperature (SAT)

sensor. The outdoor air temperature (OAT) sensor is included

in the FIOP/accessory EconoMi$er

®

2 package.

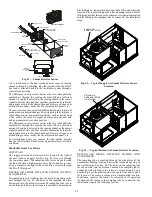

Sensory/Accessory Installation

There are a variety of sensors and accessories available for the

RTU Open. Some of these can be factory or field installed, while

others are only field installable. The RTU Open controller may

also require connection to a building network system or building

zoning system. All field control wiring that connects to the RTU

Open must be routed through the raceway built into the corner

post of the unit or secured to the unit control box with electrical

conduit. The unit raceway provides the UL required clearance be

-

tween high and low-voltage wiring. Pass the control wires through

the hole provided in the corner post, then feed the wires thorough

the raceway to the RTU Open. Connect the wires to the removable

PCB connectors and then reconnect the connectors to the board.

Fig. 51 — RTU Open Control Module

1. LonWorks is a registered trademark of Echelon Corporation.

2. Modbus is a registered trademark of Schneider Electric.

IMPORTANT: Refer to the specific sensor or accessory

instructions for its proper installation and for rooftop unit

installation refer to base unit installation instructions and the

unit’s wiring diagrams.

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury, death and/or equipment damage.

Disconnect and lockout/tag-out electrical power before

wiring the RTU Open controller.

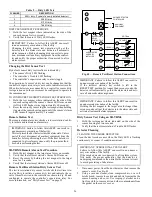

J4

J2

J1

J5

J5

J22

J17

J19

J14

J11

J22

J3

J13

J12

J15

J20

Network Comm

Configurable - Input_8

24 V

AC

Configurable - Input_5

24 V

AC

Configurable - Input_3

24 V

AC

Input_9 (Humidistat)

24 V

AC

24 V

AC

Input _8 (Enthalpy)

AO-1 (ECON)

Gnd

(OA

T)

Gnd

(SA

T)

Input_5 (SMK)

Input_4

(R)

BO-5

(Y1)

BO-4

(Y2)

BO-3

(W1)

BO-2

(W2)

BO-1

(G)

Gnd

Input_3

(X)

24 V

AC IN

+24 VDC

Input_2 (CO2/RH)

Gnd

+24 VDC

Input_1 (CO2/RH)

Gnd

Board Power

(AO-1)

0-10VDC

4-20mA

BO-6

(H) Dehumidification

BO-8

(Power Exhaust)

LonWorks

Option Card

Port

Example set for

BACnet MS/TP

and 76.8K baud

(1, 2, and 4 ON)

Protocol Selector

SPT (temp input)

BACnet, Modbus, or N2

(LON connection J15)

SPT (common)

SPT (offset input)

*Remove

both for 0-5V

AO-2

GND

(0-10V or 2-10V)

BO-7

(Reversing Valve/High Speed Fan/Y3)

3-Volt

Lithium

Battery

BO-1

BO-2

BO-3

BO-4

BO-5

BO-6

BO-7

BO-8

VFD Output/IDF Output

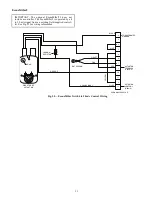

Содержание 547K

Страница 94: ...94 APPENDIX D WIRING DIAGRAMS Fig I 547K 04 06 Power Wiring Diagram 208 230 1 60 ...

Страница 95: ...95 APPENDIX D WIRING DIAGRAMS Fig J 547K 04 07 Power Wiring Diagram 208 230 3 60 ...

Страница 96: ...96 APPENDIX D WIRING DIAGRAMS Fig K 5047K 04 07 Power Wiring Diagram 460 575 3 60 ...