50

2.

Cooling Mode

The thermostat “calls for cooling.”

a. Single--Speed Cooling

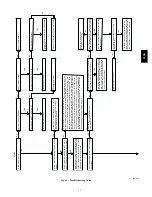

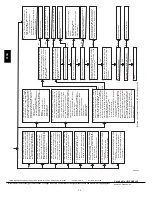

(See Fig. 25 -- 32 for thermostat connections)

The thermostat closes the R--to--G--and--Y circuits. The

R--to-- Y circuit starts the outdoor unit, and the

R--to--G--and--Y/Y2 circuits start the furnace blower

motor BLWM on COOL speed.

The electronic air cleaner terminal EAC--1 is energized

with 115 vac when the blower motor BLWM is operating.

When the thermostat is satisfied, the R--to--G--and--Y

circuits are opened. The outdoor unit will stop, and the

furnace blower motor BLWM will continue operating on

the COOL speed for an additional 90 seconds. Jumper

Y/Y2 to DHUM to reduce the cooling off--delay to 5

seconds. (See Fig. 24.)

b.

Two--Speed Cooling

(See Fig. 25 -- 32 for thermostat connections.)

The thermostat closes the R--to--G--and--Y1 circuits for

low--cooling or closes the R--to--G--and--Y1--and--Y2

circuits for high--cooling. The R--to--Y1 circuit starts the

outdoor unit on low--cooling speed, and the

R--to--G--and--Y1 circuit starts the furnace blower motor

BLWM on low--cool speed (same speed as FAN). The

R--to--Y1--and--Y2 circuits start the outdoor unit on

high--cooling speed, and the R--to--Gand-- Y/Y2 circuits

start the furnace blower motor BLWM on COOL speed.

The electronic air cleaner terminal EAC--1 is energized

with 115 vac whenever the blower motor BLWM is

operating.

When the thermostat is satisfied, the R--to--G--and--Y1 or

R--to--G--and--Y1 and Y2 circuits are opened. The

outdoor unit stops, and the furnace blower BLWM and

electronic air cleaner terminal EAC--1 will remain

energized for an additional 90 seconds. Jumper Y1 to

DHUM to reduce the cooling off--delay to 5 seconds. (See

Fig. 24.)

3.

Thermidistat Mode

(See Fig. 26--29 for Thermidistat connections.)

The dehumidification output, DHUM on the Thermidistat

should be connected to the furnace control thermostat

terminal DHUM. When there is a dehumidify demand, the

DHUM input is activated, which means 24 vac signal is

removed from the DHUM input terminal. In other words,

the DHUM input logic is reversed. The DHUM input is

turned ON when no dehumidify demand exists. Once 24

vac is detected by the furnace control on the DHUM input,

the furnace control operates in Thermidistat mode. If the

DHUM input is low for more than 48 hours, the furnace

control reverts back to non--Thermidistat mode.

The cooling operation described in item 2. above also

applies to operation with a Thermidistat. The exceptions

are listed below:

a. When the R--to--G--and--Y1 circuit is closed and there is

a demand for dehumidification, the furnace blower motor

BLWM will continue running at low--cool speed (same

speed as FAN).

b. When the R--to--G--and--Y/Y2 circuit is closed and there

is a demand for dehumidification, the furnace blower

motor BLWM will drop the blower speed from COOL

to HEAT for a maximum of 10 minutes before reverting

back to COOL speed. If there is still a demand for

dehumidification after 20 minutes, the furnace control

CPU will drop the blower speed back to HEAT speed.

This alternating 10-- minute cycle will continue as long

as there is a call for cooling.

c. When the “call for cooling” is satisfied and there is a

demand for dehumidification, the cooling blower--off

delay is decreased from 90 seconds to 5 seconds.

4.

Continuous Blower Mode

When the R--to--G circuit is closed by the thermostat, the

blower motor BLWM will operate on continuous--blower

speed (can be adjusted to FAN, HEAT, or COOL speed) at

the thermostat. Factory default is FAN speed. Terminal

EAC--1 is energized as long as the blower motor BLWM is

energized. During a call for heat, the blower BLWM will

stop during igniter warm--up (17 seconds), ignition (7

seconds), and blower--ON delay (25 seconds), allowing

the furnace heat exchangers to heat up more quickly, then

restarts at the end of the blower--ON delay period at HEAT

speed.

In heating, the furnace control CPU will hold the blower

motor BLWM at HEAT speed during the selected

blower--OFF

delay

period

before

reverting

to

continuous--blower speed. When the thermostat “calls for

low--cooling,” the blower motor BLWM will switch to

operate at low--cool speed (same speed as FAN). When the

thermostat is satisfied, the blower motor BLWM will

operate an additional 90 seconds on low--cool speed (same

speed

as

FAN)

before

reverting

back

to

continuous--blower speed.

When the thermostat “calls for high--cooling”, the blower

motor BLWM will operate at COOL speed. When the

thermostat is satisfied, the blower motor BLWM will

operate an additional 90 seconds on COOL speed before

reverting back to continuous--blower speed.

When the R--to--G circuit is opened, the blower motor

BLWM will continue operating for an additional 5

seconds, if no other function requires blower motor

BLWM operation.

Continuous Blower Speed Selection from Thermostat

--To select different continuous--blower speeds from the

room thermostat, momentarily turn off the FAN switch or

pushbutton on the room thermostat for 1--3 seconds after

the blower motor BLWM is operating. The furnace control

CPU will shift the continuous--blower speed from the

factory setting of FAN to HEAT speed. Momentarily

turning off the FAN switch again at the thermostat will

shift the continuous--blower speed from HEAT to COOL.

Repeating the procedure will shift the continuous--blower

speed from COOL to FAN speed. The selection can be

changed as many times as desired and is stored in the

memory to be automatically used following a power

interruption.

313A

Содержание 313AAV

Страница 41: ...41 Table 13 Orifice Size and Manifold Pressure In wc for Gas Input Rate A08220 313A...

Страница 42: ...42 Table 13 Orifice Size and Manifold Pressure In wc for Gas Input Rate CONT A08220A 313A...

Страница 44: ...44 Table 14 Orifice Size And Manifold Pressure In wc For Gas Input Rate A08221 313A...

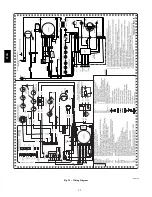

Страница 52: ...52 A08176 Fig 59 Wiring Diagram 313A...