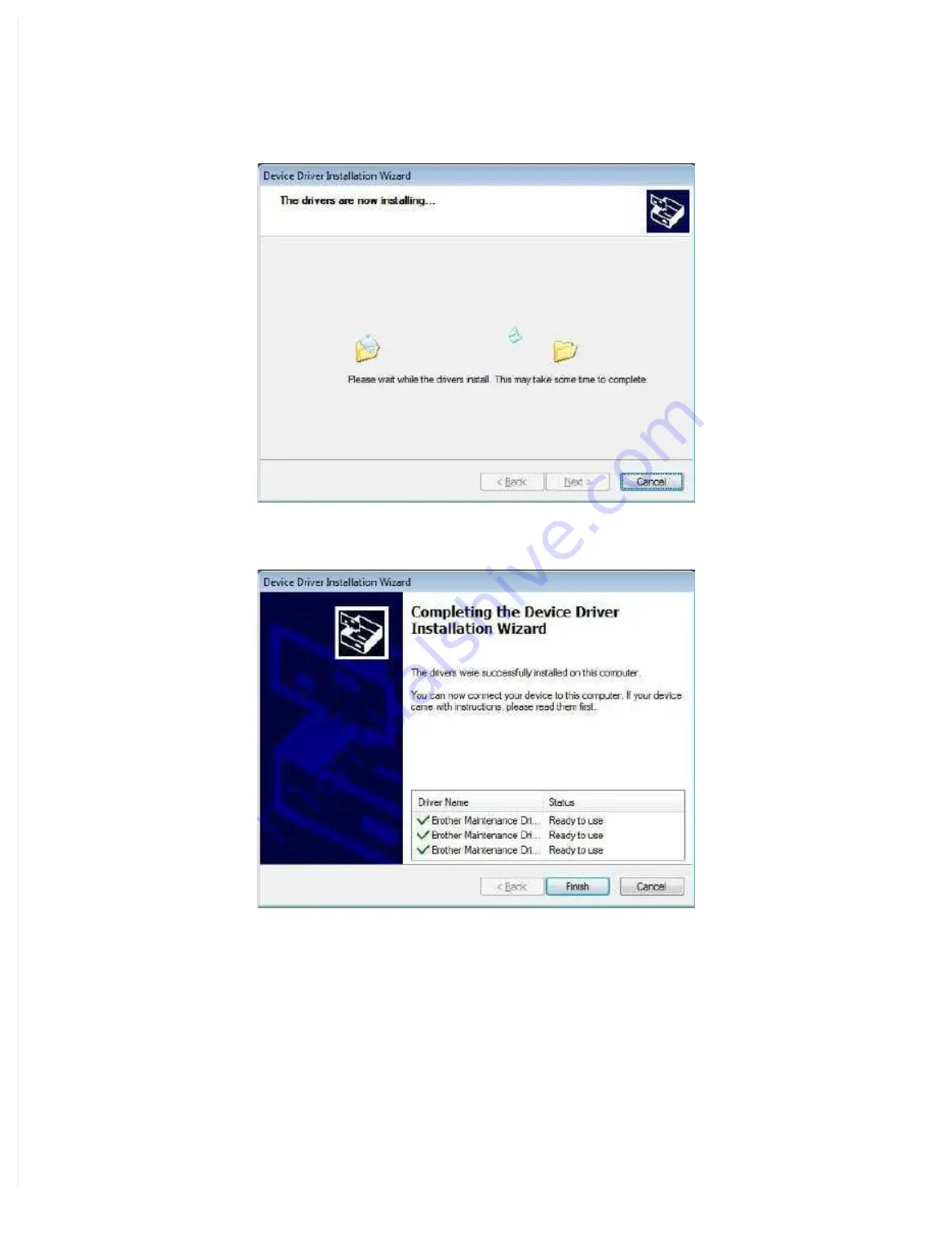

The following screen is displayed during installation.

(4) Wait for the following screen to appear and click [Finish].

(5) Plug the AC cord of the machine into an electrical outlet.

(6) Enter the maintenance mode.

(Refer to “1.1 How to Enter Maintenance Mode” in Chapter 5.)

(7) Connect the machine to your computer using a USB cable and the installation will be

performed automatically.

Содержание DCP-7090

Страница 28: ...2 10 Confidential MP models Fig 2 6 Feed from MP tray Eject to back side Back side Front side ...

Страница 29: ...2 11 Confidential 2 2 2 Scanner part Fig 2 7 Document feed path ...

Страница 42: ... Electrodes location of main body Fig 2 12 Electrodes location of the drum unit and process unit Fig 2 13 ...

Страница 64: ...2 PACKING Fig 3 1 Option carton Carton Polystyrene pad ASSY Spacer carton Option carton TBOX ...

Страница 106: ... Print adjustment test pattern Fig 5 11 ...

Страница 111: ... Test pattern Fig 5 19 ...

Страница 114: ......

Страница 115: ...CHAPTER 7 PERIODICAL MAINTENANCE 1 PERIODICAL REPLACEMENT PARTS There are no parts to be replaced periodically ...