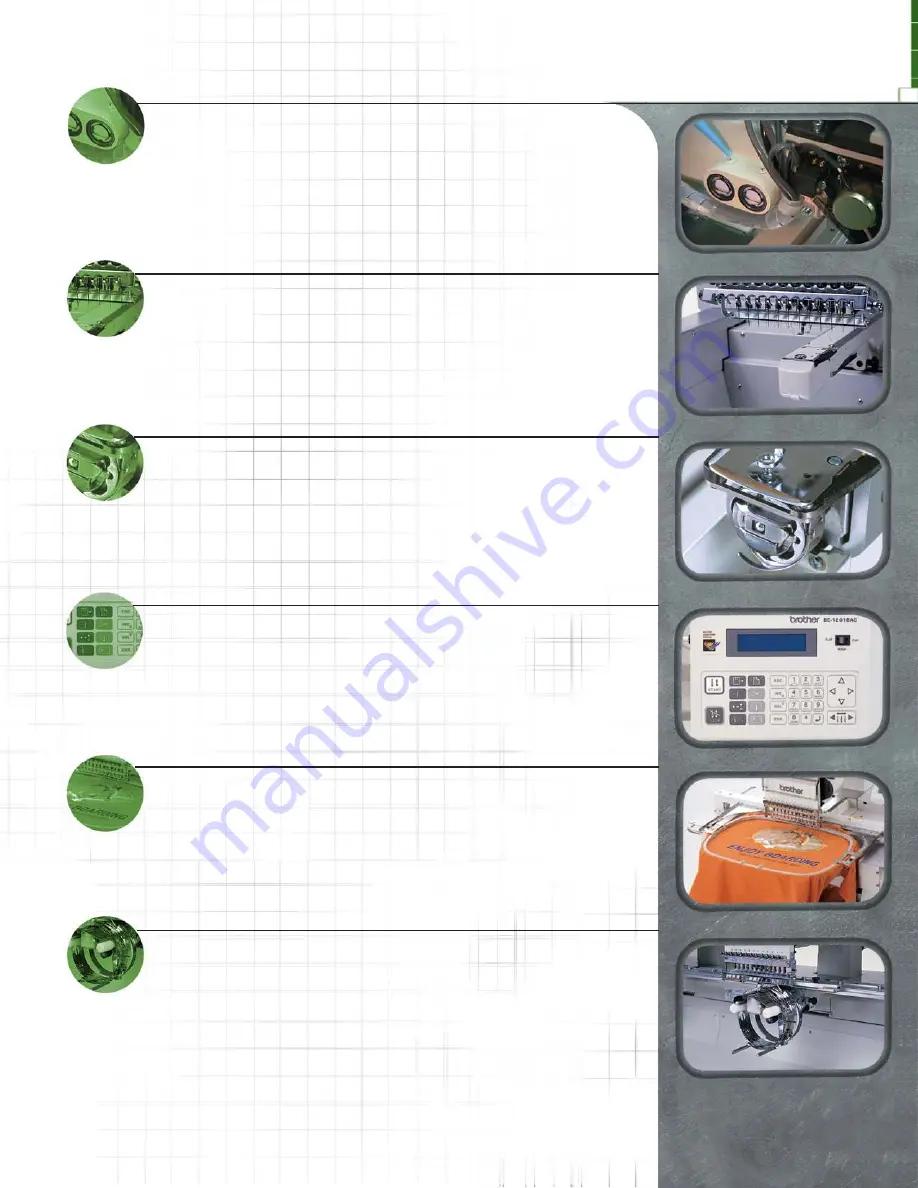

AUTOMATIC LUBRICATION SYSTEM

EASY-TO-USE CONTROL PANEL

Brother’s unique wick oiling system significantly reduces machine maintenance

downtime. Oil is poured into a conveniently located reservoir on the machine, and a

wick that is threaded through the internal workings of the sewing head delivers oil

when and where it is needed, eliminating the time-consuming task of oiling

numerous hard-to-reach locations.

Developed by Brother, the cam-driven presser foot allows the machine to run faster and

quieter. The precise movement of the cam reacts faster than the previous spring-loaded

technology and reduces the noisy pounding of the presser foot on the throat plate. The

single presser foot also facilitates increased machine speed and less maintenance.

JUMBO BOBBIN

Maximize system productivity with fewer bobbin changes with the larger capacity,

jumbo “M” style bobbins. Brother perfected the performance of the jumbo bobbin by

designing the cams and gears inside the sewing head to accommodate the longer

rotation of the larger bobbin.

Start sewing faster with the simple, logical commands found on the control panel. For

example, the hoop feed button moves the pantograph out from under the needles for

trouble-free applique placement and easier loading and unloading of hoops.

MEMORY RETENTION

Resume stitching a partially complete design after the machine has been turned off,

unplugged, or even after power failure. Shut the machine off to work with a customer,

go home for the evening, or even move the machine across town and never lose a

stitch or go off registration — another Brother first.

SINGLE CAM-DRIVEN PRESSER FOOT

INDIVIDUAL CAP FRAME ADJUSTMENT

Adjust the center point of the cap on each head independently while it’s in the frame

and mounted on the machine. Eliminate off-center designs and time-consuming

framing adjustments with this advanced cap frame driver design.

Содержание BE-0901E-AC

Страница 1: ...BROTHER EMBROIDERY SYSTEMS ...